Sizing dispersion

A slurry and composition technology, applied in the field of preparing the aqueous dispersion, can solve problems such as limiting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

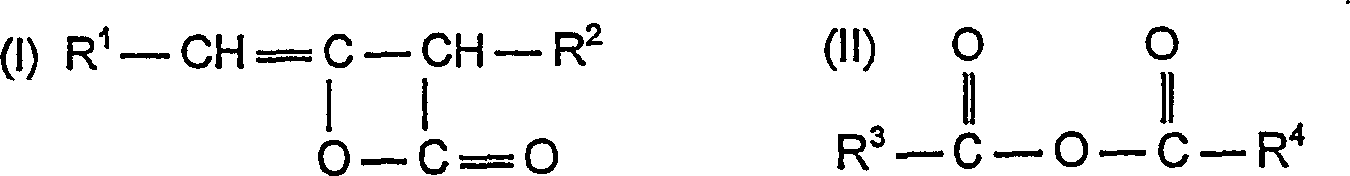

Method used

Image

Examples

Embodiment 1

[0032] The emulsion in this example is made by adding a substantially anhydrous composition of alkyl ketene dimer (AKD), nonionic surfactant, anionic surfactant and monohydric alcohol to water at a temperature of 60°C to prepare. The resulting aqueous mixture was stirred at 60° C. for 30 minutes (magnetic stirrer, approximately 400 rpm). Standard grade AKD supplied by Eka Chemicals AB was used in all compositions (emulsions). The specific surfactants and alcohols present in the composition and their ratios (amounts) are evident from Table 1 below.

[0033] The stability and particle size of the emulsion were measured. After emulsification in a flat-bottomed test tube, the emulsion was kept at 60° C. for 1 hour, and then the serum height of the emulsion was measured to evaluate its stability. In Table 1, the stability is represented by an integer from 1 to 5, wherein 1 indicates that the stability of the emulsion is poor and 5 indicates that the stability of the emulsion is ...

Embodiment 2

[0040] Two emulsions described in Example 1 were prepared containing equal weights of 7.23 grams of alkylketene dimer, 0.67 grams of hexa(ethylene glycol) undecane (C 11 E. 6 ) and 0.34 g of calcium dodecylbenzenesulfonate (Ca-DBS, 65% active). However, one emulsion referred to herein as Emulsion 1 (according to the invention) also contained 0.80 grams of dodecanol. Emulsion 1 further contained 16.04 grams of water, while emulsion 2 (without dodecanol) contained 16.84 grams of water. The stability and particle size of these two emulsions were measured according to the method shown in Example 1, and the results are shown in Tables 3 and 4.

[0041] lotion

D(v,0.5)μm

D(v,0.9)μm

1

17.84

37.39

2

36.83

78.89

[0042] *The equipment used to measure the particle size is different from that used in Example 1.

[0043] lotion

Emulsion height (mm)

Transparent phase height (mm)

Ratio (e...

Embodiment 3

[0047] Two sizing emulsions (Emulsion 1 and 2) were prepared, both containing 0.15 grams of AKD, 0.0075 grams of Ziegler alcohol acetate (C 12-14 EO(8)), 0.0075 g tristyrenated phenol acetate PO(10)EO(25)PO(3) and 0.0075 g calcium dodecylbenzenesulfonate (Ca-DBS, 65% active). In addition to the above components, 0.0167 g of dodecanol and 29.81 g of water were added to Emulsion 2 (according to the invention), whereas only 29.83 g of water were added to Emulsion 1 in addition to the above components. Both emulsions were prepared as described in Example 1. Emulsion 1 and Emulsion 2 were evaluated for particle size distribution (Table 6) and sizing effect (Table 7). Particle size was measured according to the method of Example 1. The sizing effect was measured using the cobb60 method, using similar ingredients to Example 2 and the same retention system with the same loading.

[0048] lotion

[0049] lotion

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight-average molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com