Automatic flatness measuring device and method

A technology of automatic measurement and flatness, applied in the direction of length measuring device, metal processing equipment, metal rolling, etc., can solve the problems of low efficiency, long downtime occupied by measurement, high labor intensity, etc., and achieve high efficiency and measurement The effect of high speed and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

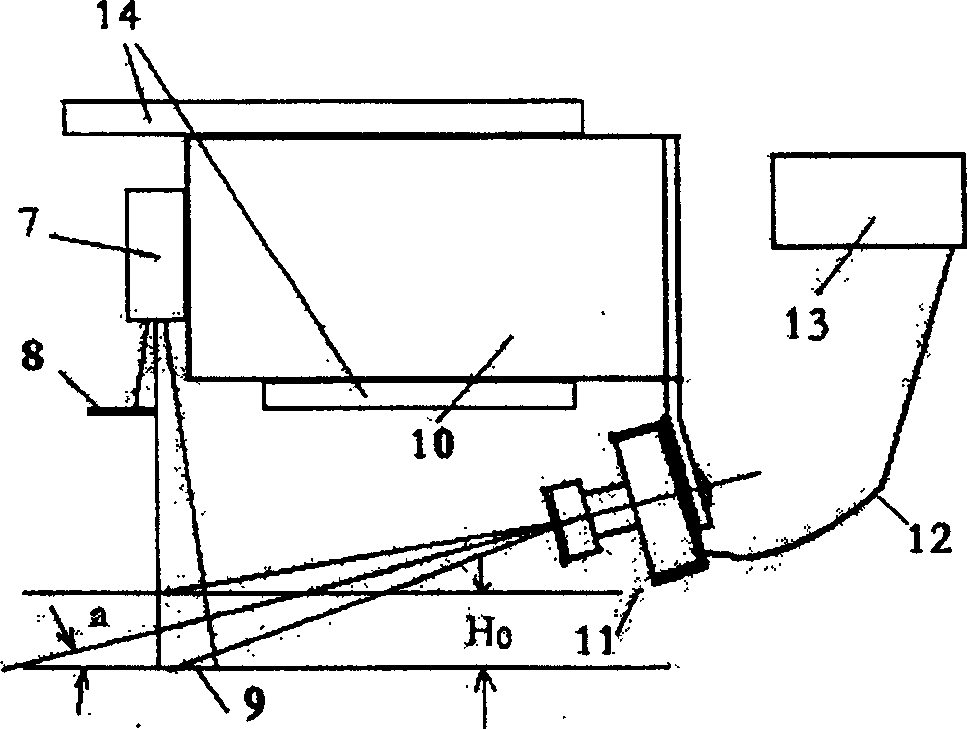

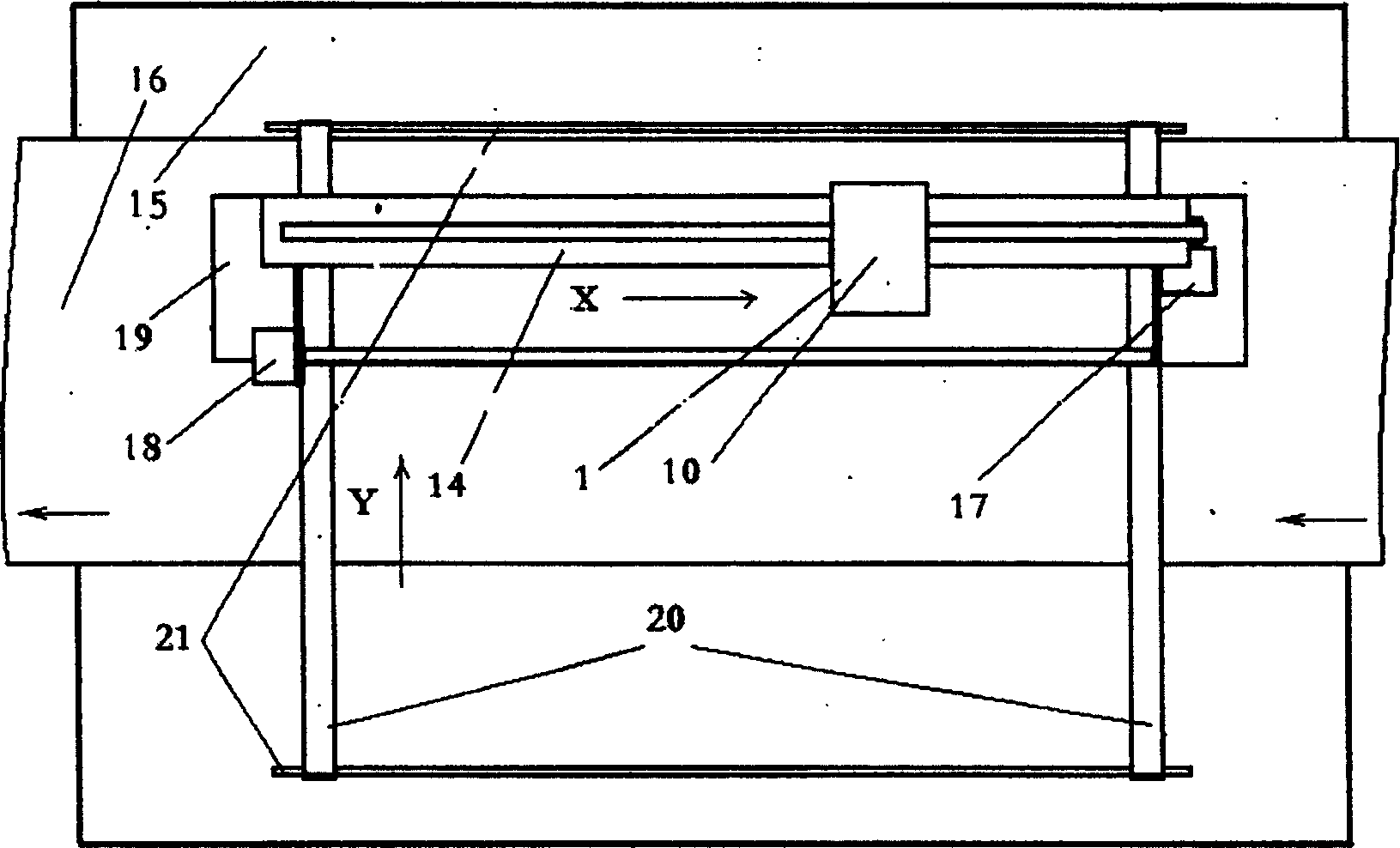

[0061] The flatness of the plate is measured with a laser flatness automatic measuring device.

[0062] The semiconductor laser beam expansion light source adopts a 2mW semiconductor laser 7, which is fixed on the probe slider 10. The laser optical axis is perpendicular to the measurement platform 15 plane, and the diameter of its divergent light spot on the measurement platform 15 far away from 90mm is about 33mm; on the optical path A light blocking plate 8 is set at 22mm away from the measuring platform 15 (22mm is greater than Ho), so that the light spot just becomes a semicircle, and the diameter is parallel to the X guide rail 14; on the probe slider 10, a bracket is used to fix the black and white CCD camera 11, Its model is BL-210B, 420 lines, equipped with an 8mm lens, the a angle is about 24 degrees, and the distance from the center of the laser spot is about 60mm. The output of the CCD camera 11 is sent to the VT-210 video image acquisition card 13 inserted in the P...

Embodiment 2

[0072] The laser flatness automatic measuring device measures the plate.

[0073]It is characterized in that 23 lasers 25 are installed on the measuring frame 29, and they are vertically projected on the plate to be measured. The light blocking plate 32 adopts a stainless steel alloy ruler with a smooth edge, which is perpendicular to and intersects with the optical axes of the lasers 25 . The light spot projected by each laser on the measuring plate is a semicircle, and the diameter image is a straight line. 23 BL-210B CCD camera heads 11 with 8mm lens are arranged closely in a line on the measurement frame 29, and the angle a of the installation is about 24 degrees. Each CCD camera is about 60 mm away from the center of the laser spot of the corresponding laser 7 . Each camera 11 picks up a small segment of images in the X direction of the survey line, and 23 CCD cameras 11 can measure the wave shape of the 690mm long survey line in the X direction. The output of each CCD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com