Curing and cleaning technology in the process of processing dry-cure ham

A dry-cured ham, processing technology, applied in the field of pickling and cleaning technology, can solve the problems of high labor intensity and achieve the effect of reducing labor intensity, high degree of automation, and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

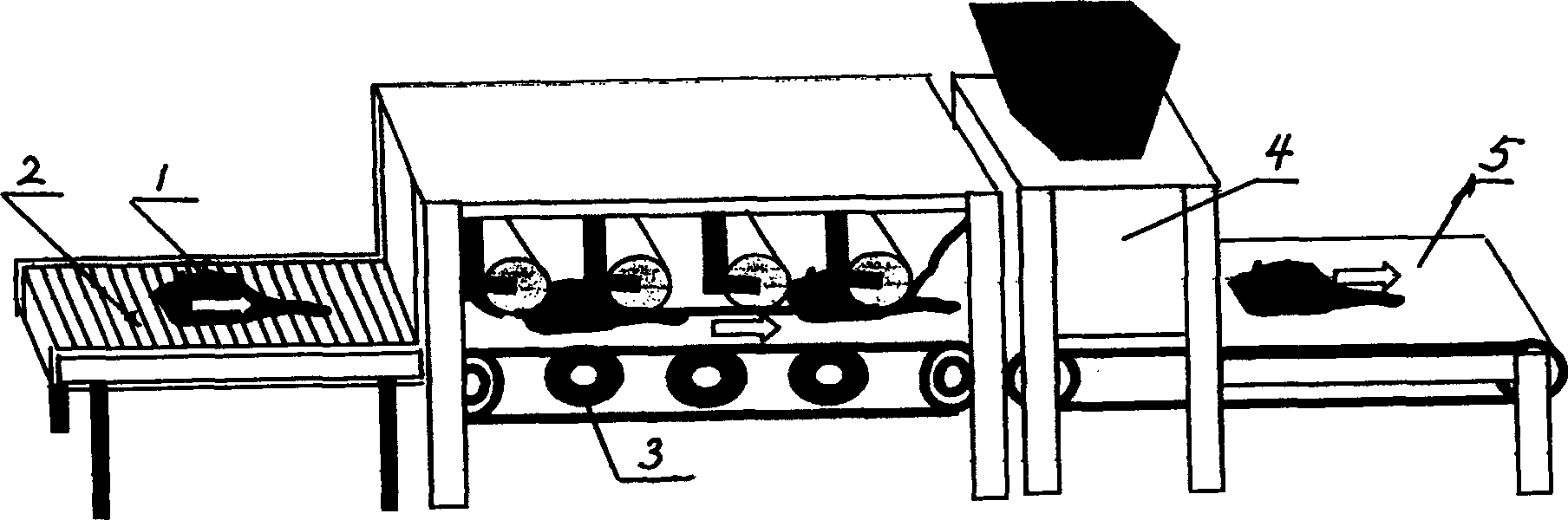

[0015] The pickling process of the embodiment of the present invention is as follows: first place the selected pork leg 1 on the conveying raceway 2, and manually add salt to the side of the pork leg 1; then send the salted pork leg 1 into the Tumble and knead in the tumbler 3; the pork leg 1 after the tumbling is sent to the automatic salt spreader 4 by the conveyor belt 5, and the salt is automatically added, and then the three-mark salt is manually added to the three-mark position of the bone of the pork leg 1; The final pork legs 1 are stacked and left to stand for 5 to 7 days; the whole process of adding salt, tumbling, salting and adding three swabs of salt to the standing pork legs 1 is repeated 3 to 4 times to complete the early marinating process. system. During the pickling process, the ambient temperature is controlled at 0-6°C, and the humidity is 80-90% RH. In this embodiment, the processed pork legs 1 were stacked and left to stand for 6 days; the above-mentione...

Embodiment 2

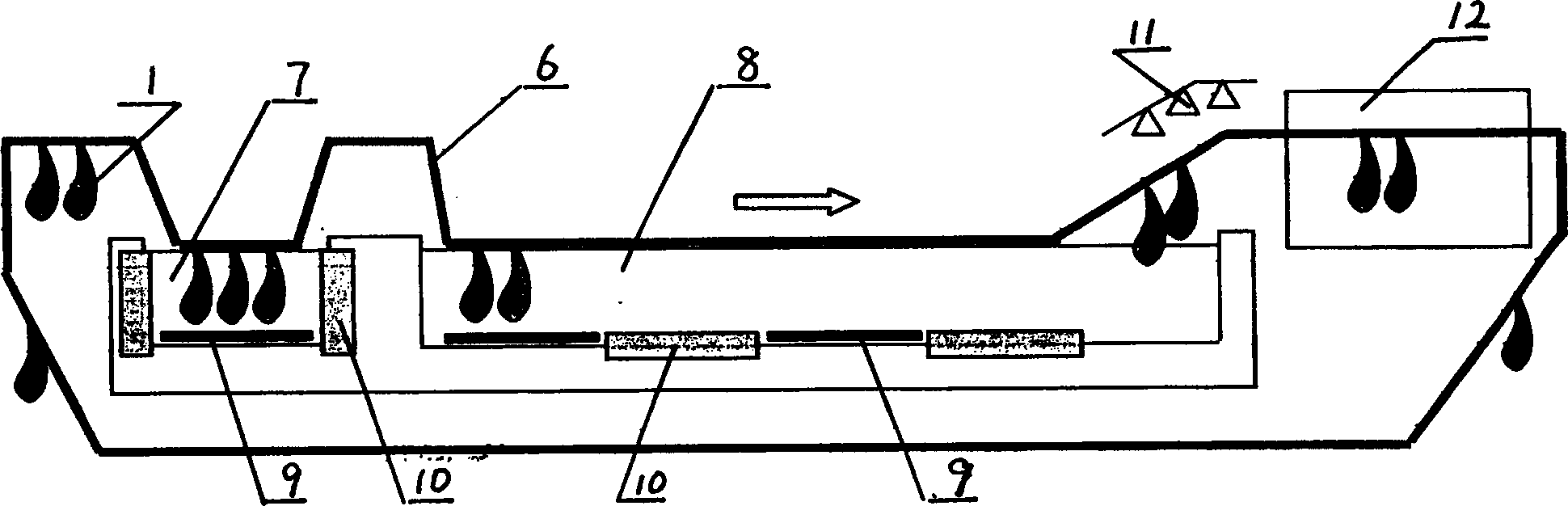

[0018] The cleaning process of the present invention is: the pork leg 1 that has been cured is sent into the first cleaning tank 7, and the salt coating on the surface is eluted; In the cleaning tank 8, the water temperature is controlled at 20-40°C, so that the excess salt on the surface is dissolved into the water; the pork leg 1 after cleaning and soaking is rinsed with clean water, and then enters the air shower equipment 12 to dehydrate and dry the surface, and enter the dry pickling Follow-up process of ham. In this embodiment, the water temperature of the second cleaning tank 8 is controlled at 35°C.

[0019] figure 2 A schematic diagram of a cleaning process flow related to the embodiment of the present invention is disclosed without limitation. It can be seen in the figure that the first cleaning tank 7 and the second cleaning tank 8 both use ultrasonic bubble combined cleaning tanks, wherein the first cleaning tank The ultrasonic generator 9 of 7 is placed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com