Rubber modified styrene resin composite

A styrene-based resin and styrene-based technology, applied in the field of rubber-modified styrene-based resin compositions, can solve the problem of reduced Izod impact strength and the inability to simultaneously improve Izod impact strength and drop-weight impact strength, drop-weight Insufficient impact strength, etc., to achieve excellent formability, drop weight impact strength, good flexural modulus, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

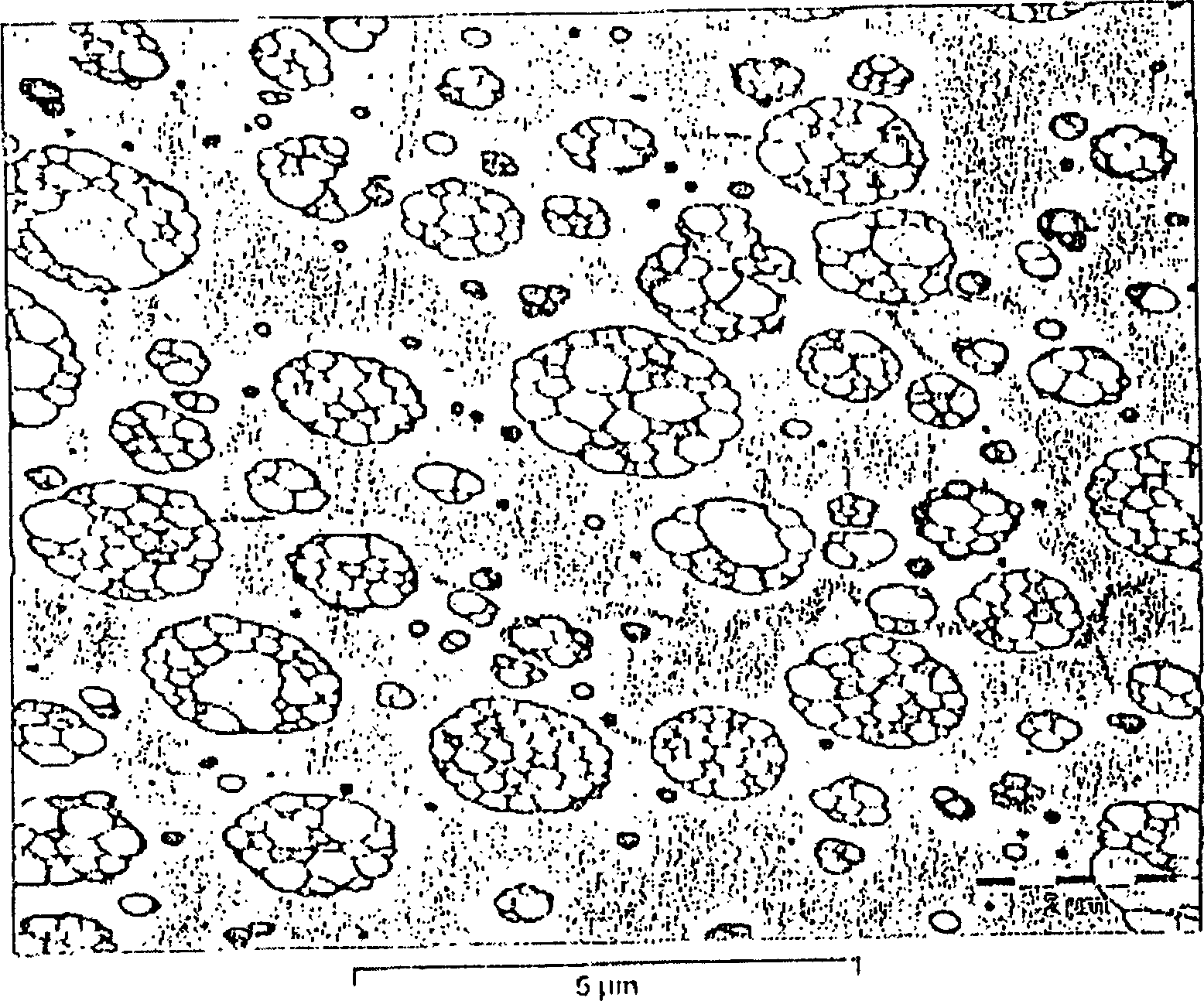

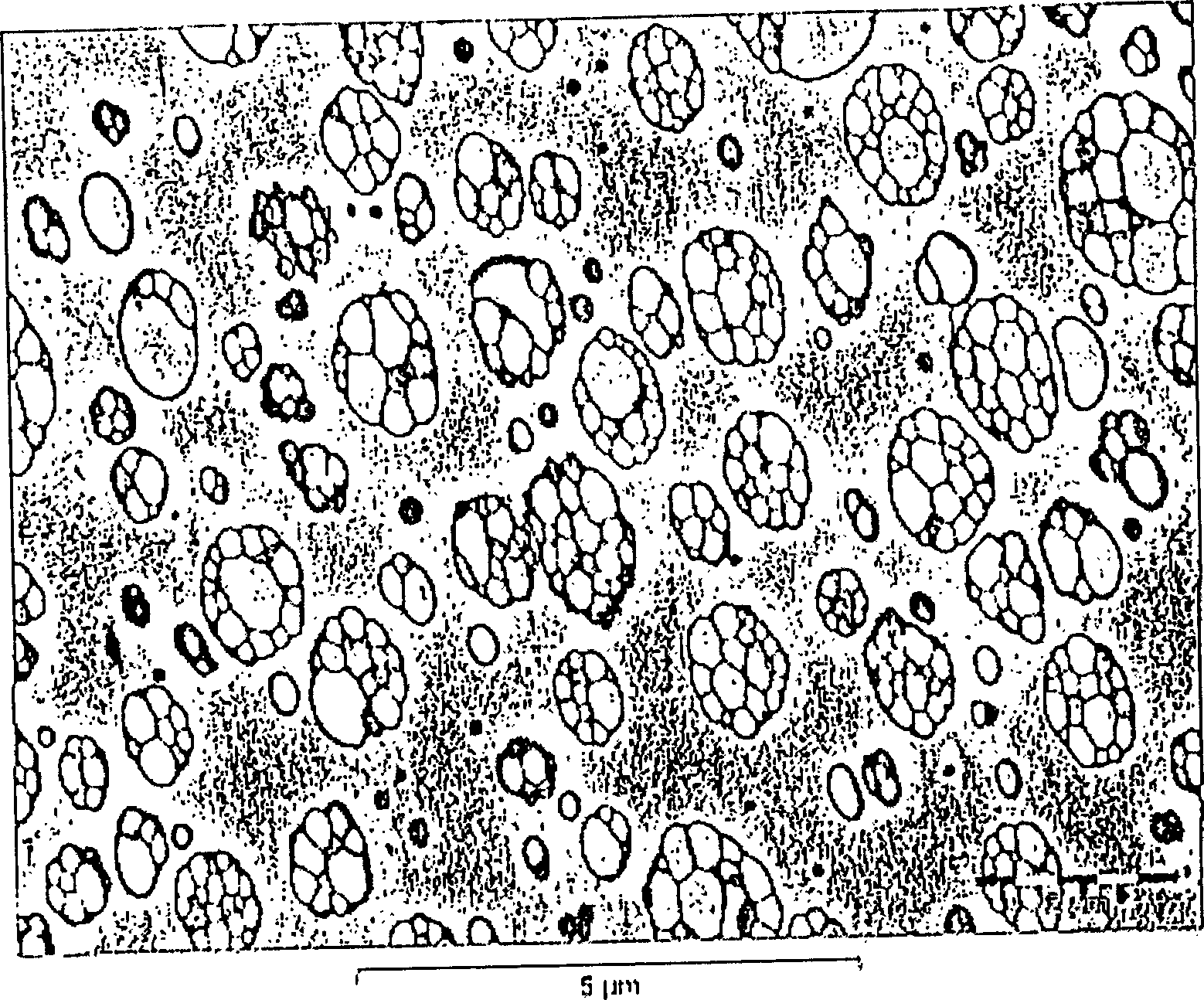

[0085] 1.5 parts by weight of styrene-butadiene block copolymer (a1) (manufactured by Chi Mei Industrial Co., Ltd., trade name KIBITON PB-511, styrene content 30% by weight), 3.0 parts by weight of cis Polybutadiene rubber (a2) (manufactured by Ube Kogyo Co., Ltd., trade name UBE-POL BR-015H) with 98 mol% formula structure, 3.0 parts by weight of polybutadiene rubber (a3) with 35 mol% cis structure (manufactured by Chi Mei Industrial Co., Ltd., trade name KIBIPOL PR-255), 92.5 parts by weight of styrene monomer (100 parts by weight in total), 6 parts by weight of ethylbenzene, 0.015 parts by weight of polymerization initiator TX- 29A, the chain transfer agent TDM of 0.025 weight part, the Ix-1076 of 0.2 weight part, the TNPP of 0.1 weight part, and the raw material solution of the zinc stearate (abbreviated as Zn-ST below) of 0.2 weight part mix, supply continuously to Three columnar flow reactors in series, the volume of the reactor is 100 liters, the internal temperature o...

Embodiment 2

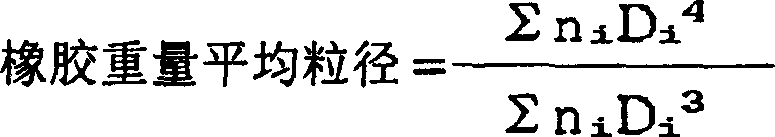

[0088]With the operating method of [Example 1], the difference is that the composition and amount of rubber are changed, that is, 1.5 parts by weight of styrene-butadiene block copolymer (a1) (Chi Mei Industrial Co., Ltd. manufactured, trade name KIBITON PB-511), 2.5 parts by weight of polybutadiene rubber (a2) with a cis structure of 96 mol % (manufactured by Ube Kogyo Co., Ltd., trade name UBE-POLBR-23H), 3.5 parts by weight of The polybutadiene rubber (a3) (manufactured by Chi Mei Corporation, trade name KIBIPOL PR-245) with a cis structure of 35 mol% had a monomer conversion rate of 80% by weight in the final reactor. The rubber component of the rubber-modified styrene-based resin composition is 9.2% by weight, and the weight-average particle diameter of the rubber particles is 2.5 μm. The manufacturing formula and physical property analysis are listed in Table 1.

Embodiment 3

[0090] With the operation method of [Example 1], the difference is that the composition and consumption of rubber are changed, that is, the block copolymer (a1) of 1.0 parts by weight of styrene-butadiene (manufactured by Chi Mei Industrial Co., Ltd., Trade name KIBITON PB-511), 2.0 parts by weight of polybutadiene rubber (a2) of 96 mol% cis structure (made by Ube Kogyo Co., Ltd., trade name UBE-POLBR-23H), 4.5 parts by weight of cis The polybutadiene rubber (a3) (manufactured by Chi Mei Corporation, trade name KIBIPOL PR-245) with a structure of 35 mol% had a monomer conversion rate of 80% by weight in the final reactor. The rubber component of the rubber-modified styrene-based resin composition is 9.2% by weight, and the weight-average particle diameter of the rubber particles is 2.8 μm. The manufacturing formula and physical property analysis are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com