Holotype photoresist composite

A technology of photoresist and composition, which is applied in the field of positive photoresist composition, can solve problems such as difficulty in application and increased coating amount of resist, and achieve the purpose of suppressing the generation of blurred spots and suppressing The generation of streak marks and the effect of suppressing drip marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

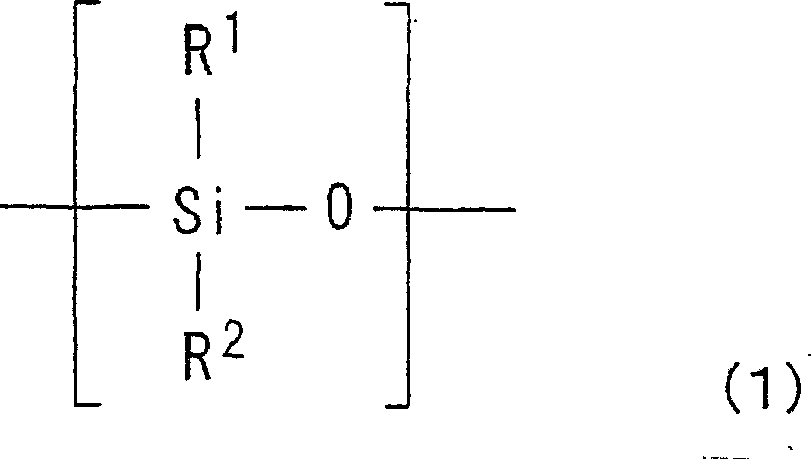

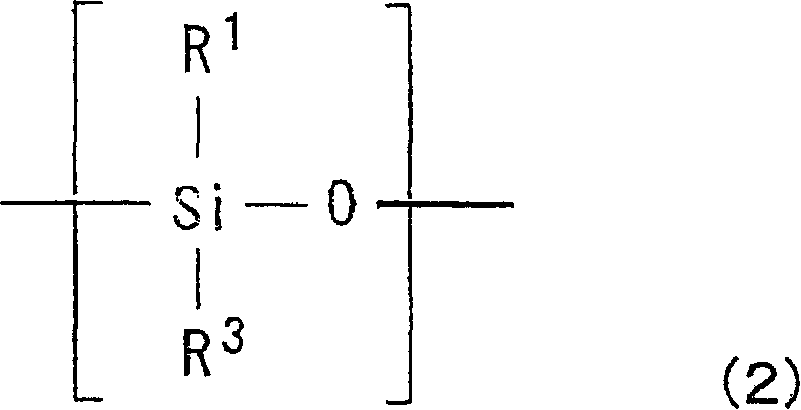

Method used

Image

Examples

Embodiment 1~2、 comparative example 1~2

[0134] In the examples and comparative examples, the photoresist compositions were prepared according to the ratio shown in Table 1, and the evaluations of blur spots, drop marks and streak marks were performed respectively. The evaluation results are shown in Table 2.

[0135] In addition, in the evaluation of photoresist pattern forming ability, on the substrate of each example, the resist pattern of 3.0 μm line & space was reproduced with a predetermined size, while in the comparative example, due to the influence of stripe marks As a result of the change in film thickness, it can be seen that a part of the resist pattern has a dimensional change.

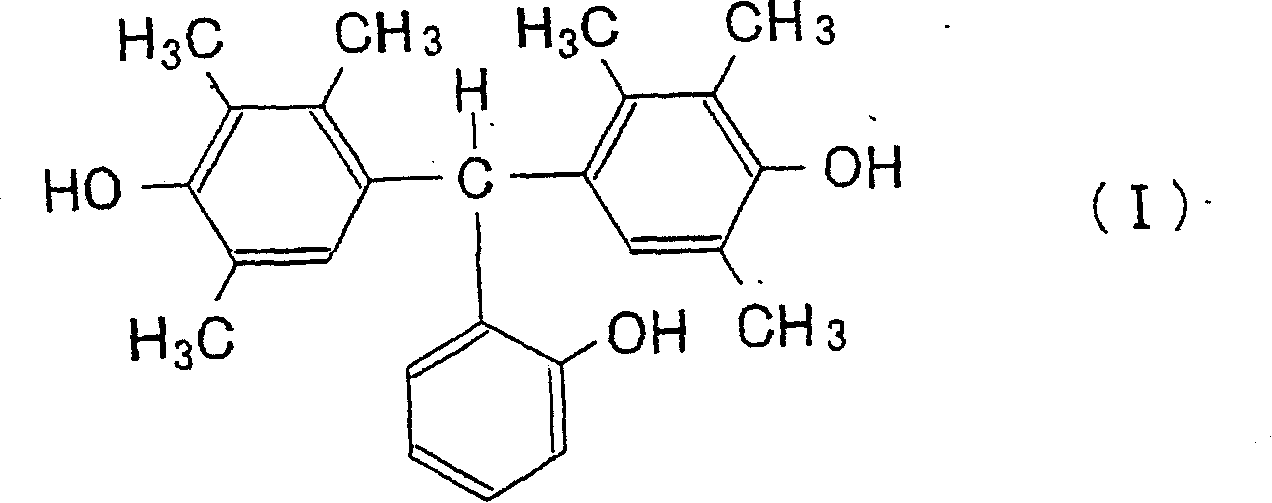

[0136] The following (a1)-(a3) were used as (A) component. (A) The compounding quantity of a component was set to 100 mass parts. In Table 1, ( / / ) represents a mixture mixed at the described mass ratio.

[0137] (a1): For the mixed phenols of m-cresol / p-cresol=30 / 70, take formaldehyde as condensing agent, carry out condensati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com