Purification of organic acid using anion exchange chromatography

An anion, inorganic anion technology, applied in separation methods, organic chemistry, separation/purification of carboxylic acid compounds, etc., can solve problems such as increasing the cost of purified acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

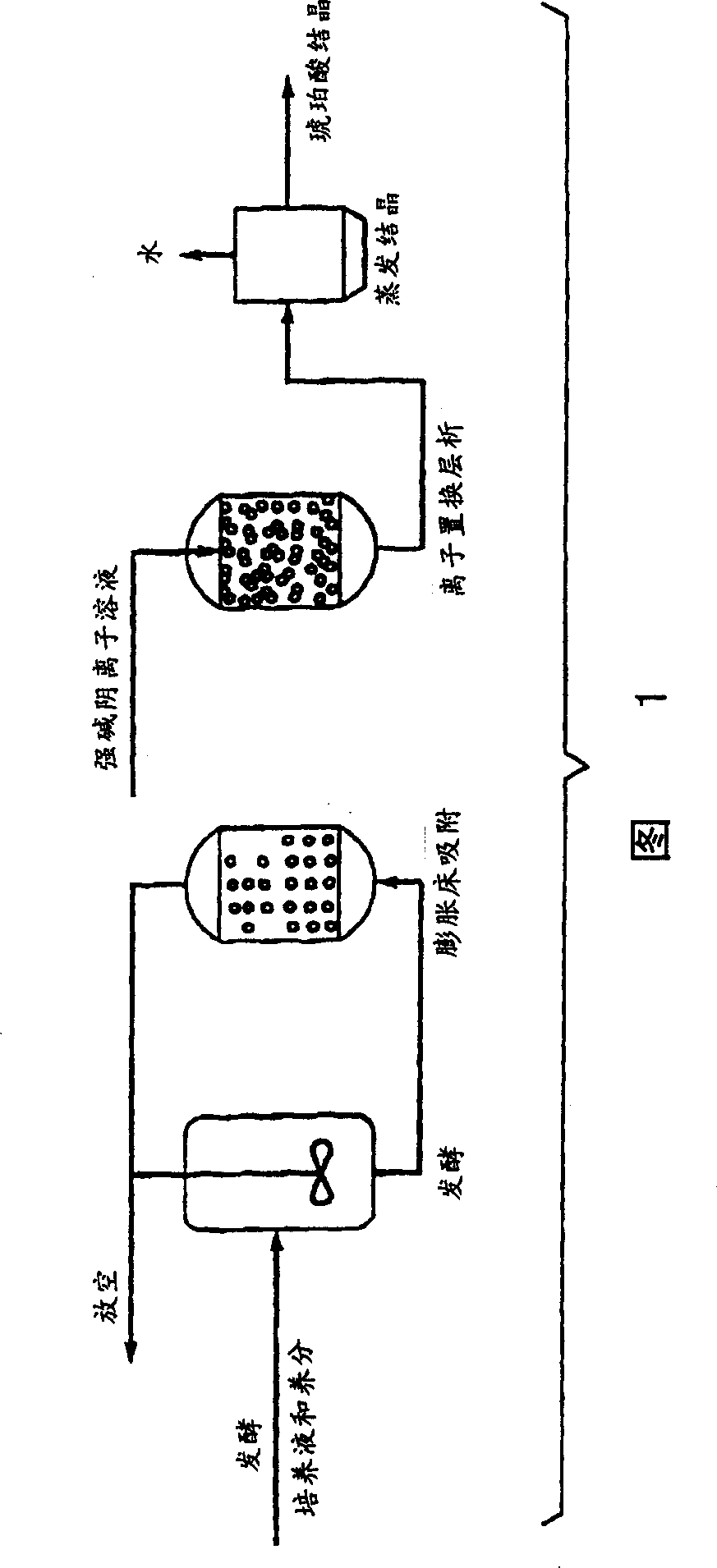

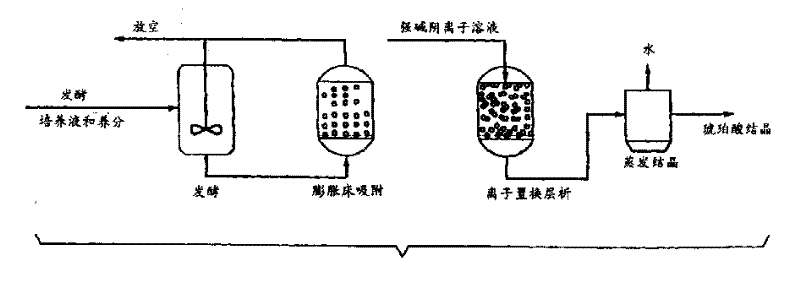

Image

Examples

Embodiment Construction

[0040] Obtain succinate from fermented broth

[0041] Total amount of succinic acid in fermentation broth before ion exchange = 4 kg

[0042] Volume of succinic acid broth before ion exchange = 4 liters

[0043] Succinate concentration determined by HPLC = 58.14 g / L

[0044] Lactate concentration determined by HPLC = 5.05 g / L

[0045] Acetate concentration determined by HPLC = 3.89 g / L

[0046]Fermentation Broth pH =

[0047] Amount of succinate (retention solution) after ion exchange = 19.2 kg

[0048] Volume of succinate solution (retention solution) after ion exchange = 19.2 liters

[0049] Succinate concentration determined by HPLC = 4.28 g / L

[0050] Lactate concentration = 0.23 g / L

[0051] Acetate concentration = 0.34 g / L

[0052] Retention solution pH =9.3

[0053] Ion exchange column bed volume = 7 liters

[0054] Ion Exchange Column Diameter =4″

[0055] Flow rate = 21.6 liters / hour

[0056] =3BV / hr

[0057] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com