Stress corrosion method for protection of core rod used in composite insulator

A composite insulator and stress corrosion technology, which is applied in the direction of surface coating liquid devices, coatings, special surfaces, etc., can solve the problems of poor stress corrosion resistance, large dispersion, no better, etc., and achieve stress corrosion resistance Performance improvement, enhancement of stress corrosion resistance, effect of improving stress corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

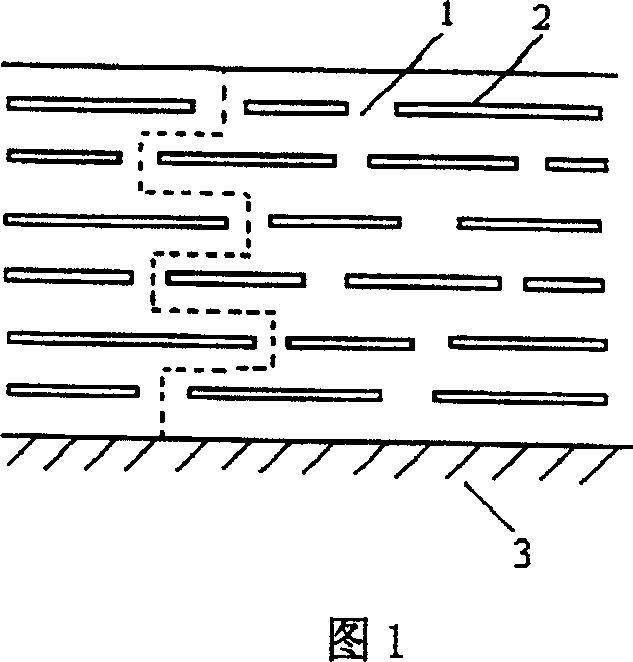

Method used

Image

Examples

Embodiment 1

[0020] In this embodiment, in order to improve the stress corrosion performance of a mandrel with a diameter of φ18mm, a coating composed of epoxy resin and glass flakes is selected. When coating the mandrel surface, a two-component coating is used. The A component is an epoxy flake coating, and the B component is a curing agent, which is blended and mixed in a ratio of 5:1. Apply the paint directly on the mandrel with a brush, wait for a few hours to cure and dry, and then apply the second time. After the second brushing, the coating will reach a thickness of 0.1mm-0.2mm. After coating, the mandrel is maintained for one week.

[0021] The stress corrosion resistance performance of the scale-containing coating mandrel produced in this embodiment was tested. During the test, according to the corresponding regulations in the electric power industry standard DL / T 810-2002, 67% of the rated load of 67kN (rated load 100kN) was applied to the original mandrel and the mandrel coated...

Embodiment 2

[0026] In this embodiment, the stress corrosion performance of the mandrel with a diameter of φ18 mm is also improved, and the high-chlorinated polyethylene glass flake coating composed of high-chlorinated polyethylene resin and glass flakes is selected. Use one-component paint, cover the surface of the core rod with a layer of coating according to the spraying method, and after the coating thickness sprayed on the surface of the core rod reaches 0.15mm, then carry out the stress corrosion test on the core rod containing scale paint according to the above test method , the test results are shown in Table 2. It can be seen from the table that the stress corrosion resistance of the mandrel is greatly improved.

[0027] Spraying times

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com