Method of preparing microsphere of ethoxyl copolymer PLGA in interferon poly acid

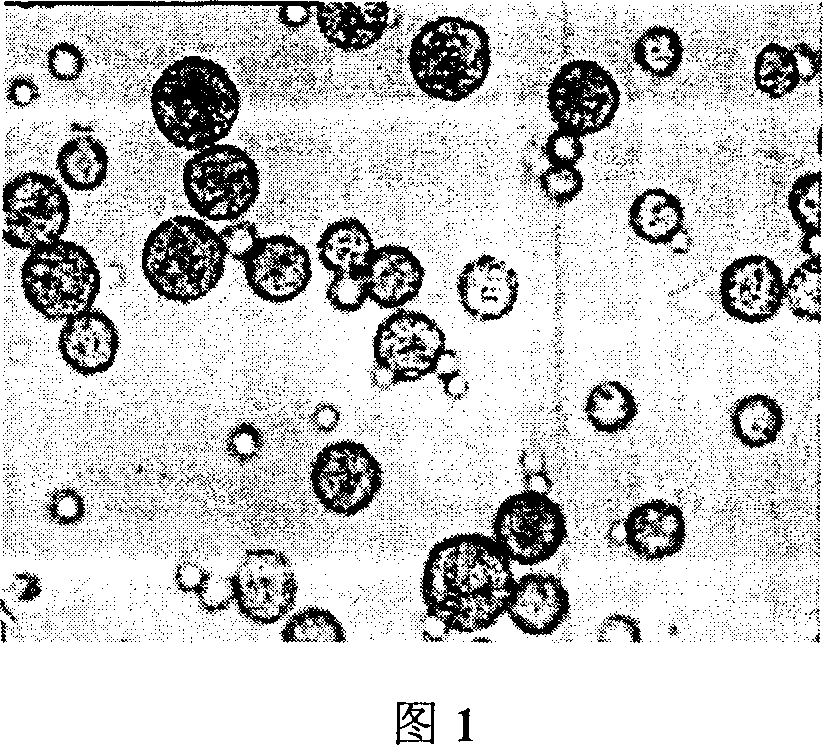

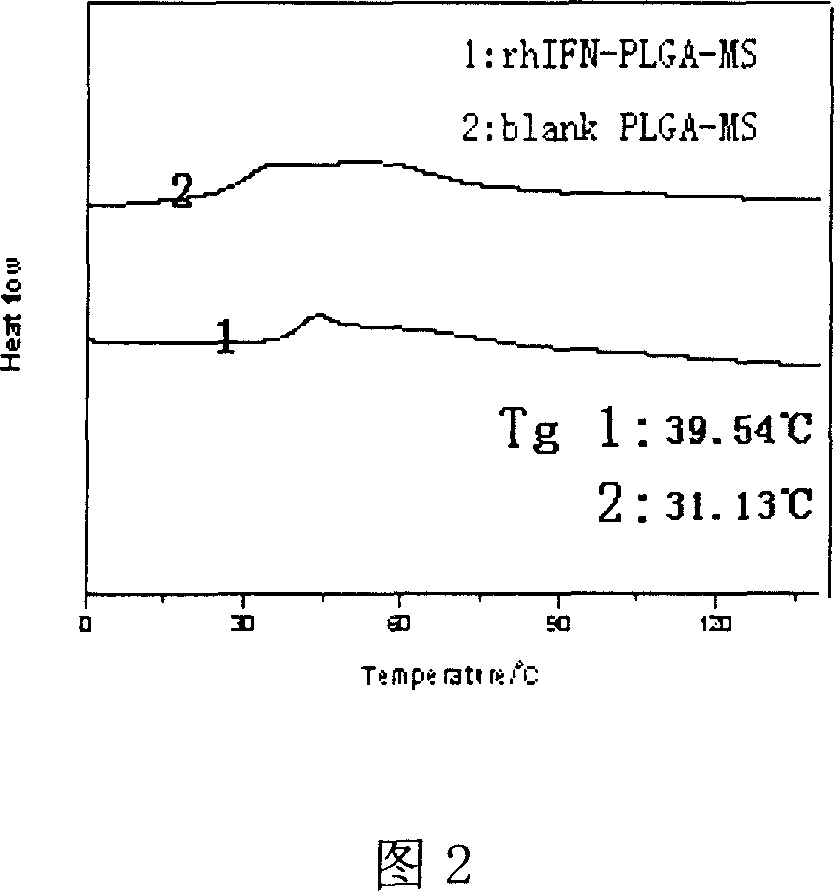

A technology of polylactic acid and interferon, applied in medical preparations with non-active ingredients, medical preparations containing active ingredients, drug combinations, etc., can solve the problems of short biological half-life, poor stability, hindering use, etc., and achieve smooth surface , Good fluidity, prolonging the effect of action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 Preparation of interferon poly(lactic-co-glycolic acid) (PLGA) microspheres

[0026] (1) Preparation of polylactic acid-glycolic acid copolymer (PLGA) solution

[0027] 400 mg of poly(lactic-co-glycolic acid) (PLGA) was dissolved in 2 ml of dichloromethane to form an organic phase (20% g / ml).

[0028] (2) Preparation of interferon PBS solution

[0029] Dissolve 40 mg of lyophilized recombinant human interferon-α for injection in 300 μl of 1% (g / ml) gelatin solution to form an internal aqueous phase;

[0030] (3) Preparation of colostrum

[0031] Inject the inner aqueous phase into the organic phase, stir and emulsify at 9000rpm for 1 minute to form colostrum (W / O);

[0032] (4) Preparation of double emulsion

[0033] Add colostrum to 300ml containing 1% (g / ml) PVA and 1% (g / ml) NaCl solution (outer water phase) under the situation of stirring at 2000rpm, emulsify for 10 minutes, emulsify into double emulsion (W / O / W);

[0034] (5) Formation of microsp...

Embodiment 2

[0039] Embodiment 2 Preparation of interferon poly(lactic-co-glycolic acid) (PLGA) microspheres

[0040] (1) Preparation of polylactic acid-glycolic acid copolymer (PLGA) solution

[0041] 600 mg of poly(lactic-co-glycolic acid) (PLGA) was dissolved in 2 ml of dichloromethane to form an organic phase (30% g / ml).

[0042] (2) Preparation of interferon PBS solution

[0043] Dissolve 60 mg of lyophilized recombinant human interferon-α for injection in 300 μl of 30% PEG400 solution to form an inner aqueous phase;

[0044] (3) Preparation of colostrum

[0045] Inject the inner aqueous phase into the organic phase, stir and emulsify for 3 minutes at 1000rpm to form colostrum (W / O);

[0046] (4) Preparation of double emulsion

[0047] Add colostrum to 200ml containing 3% (g / ml) PVA and 0.5% (g / ml) NaCl solution (outer water phase) under the situation of stirring at 1600rpm, emulsify for 20 minutes, emulsify into double emulsion (W / O / W);

[0048] (5) Formation of microspheres ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com