Three-differential focasing micro-three-dimensional super-resolution imaging method

A super-resolution imaging and differential confocal technology, which is applied to the analysis of materials, material analysis through optical means, and measurement devices, etc., can solve the problems of environmental temperature drift, confocal microscope axial tomographic precision restriction, increase, etc. , to achieve the effect of improving the signal-to-noise ratio, enhancing the anti-interference ability of the environment, and improving the defocus characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

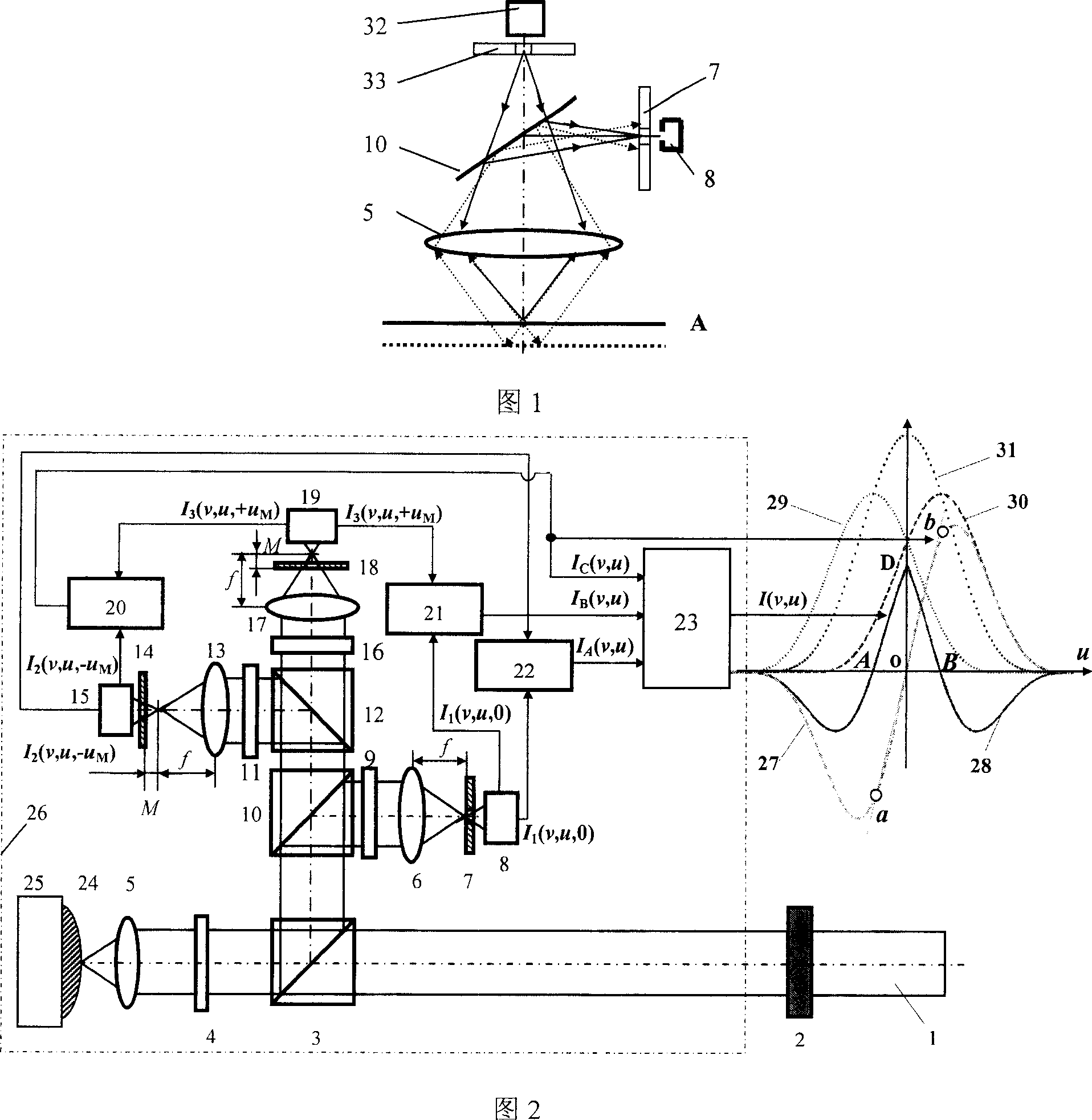

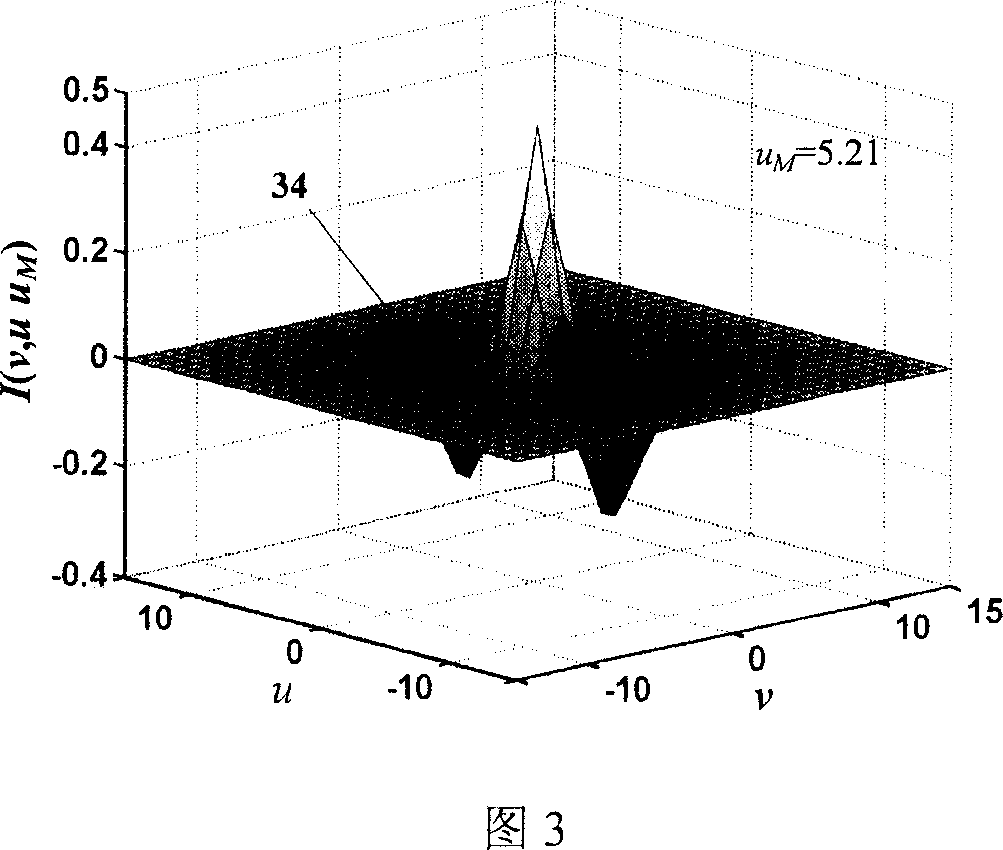

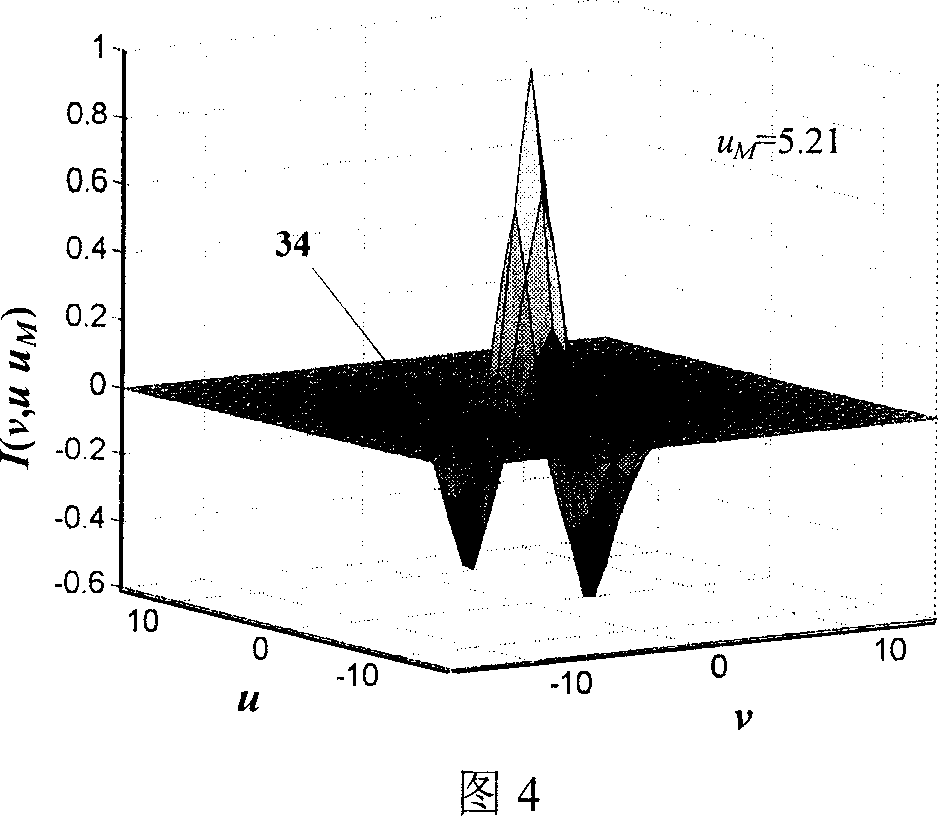

[0035] The three-differential microscopic imaging method of the present invention adopts the three-differential confocal microscopic imaging technology to arrange the receiving optical path of the confocal microscope into a three-way detection optical path of far focus, focal plane and near focus, and detects through the three-way detection system. Three-way intensity response signals with different phases are differentially subtracted in pairs to improve the axial resolution and anti-interference ability. The lateral resolution of the confocal microscope is improved through the super-resolution pupil filter confocal microscopy imaging method, so that Confocal microscopy finally achieves high performance-to-noise ratio and three-dimensional super-resolution microscopic imaging.

[0036] As shown in Figure 2, the virtual frame part 26 is a three-differential confocal microscopic optical path arrangement, and the incident light beam 1 passes through the pupil filter 2 and passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com