Sampling machine for gas analysis in metal and method for making sample

A gas analysis and sample preparation machine technology, applied in the field of chemical analysis, can solve the problems of inaccurate analysis results, inconsistent surface polishing, long sample preparation time, etc., achieve accurate analysis results, reduce labor intensity, and improve polishing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

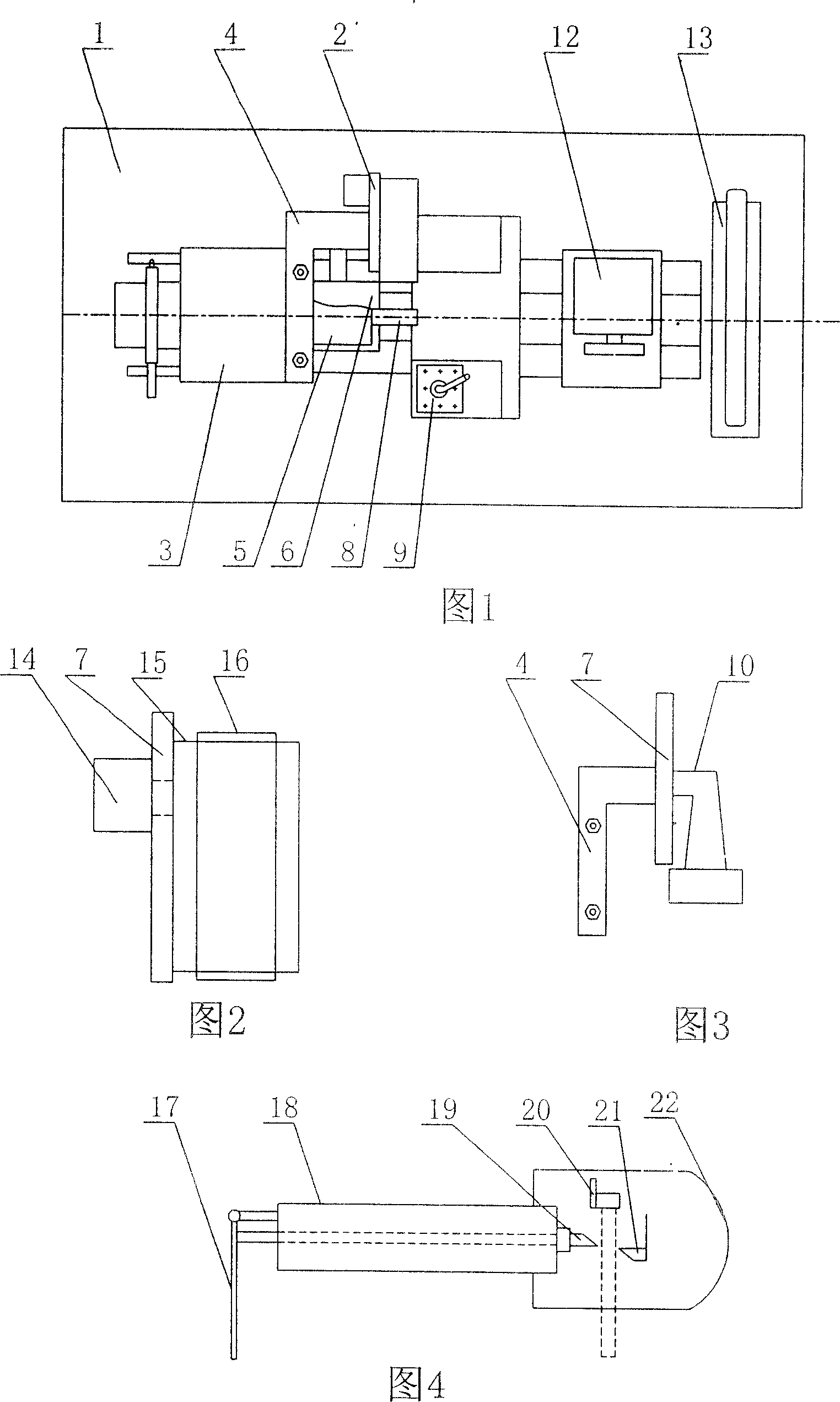

[0024] As shown in Figure 1, the sample preparation machine for gas analysis in metals includes a table top 1 mounted on the machine base, a main transmission box 3 mounted on the table top 1, a workpiece cooling device, a waterproof cover 6, and a chuck 5. Turning tool holder 9, longitudinal carriage and horizontal carriage are characterized in that a corner-shaped support frame 4 is provided on the main transmission box, and a swingable polishing device 2 is installed on the support frame 4. A grinder 12 is arranged on the upper right part of the table top 1, and a sample shearing device 13 is arranged on the right end of the table top 1.

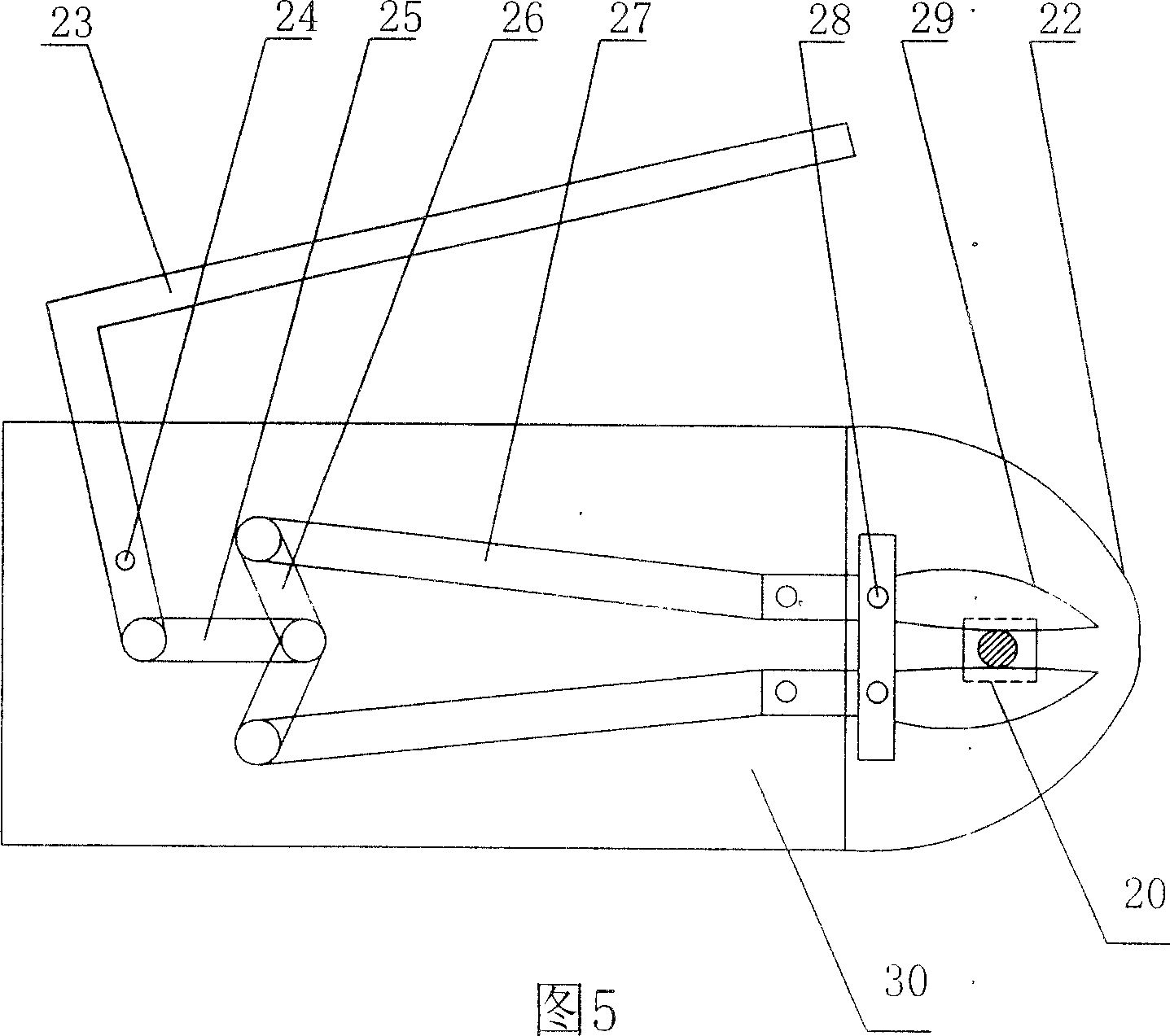

[0025] As shown in Figure 2, the swingable polishing device is an abrasive belt polishing device. A speed reduction motor 14 of 15 to 55 rpm installed on the supporting steel plate 7, an abrasive bel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com