Single frequency tuneable laser

A technology for tuning lasers and single frequency, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of inability to obtain fast frequency tuning, reduced laser reliability, different tuning sensitivity, etc., to improve reliability and Repeatability, overcoming tuning speed bottlenecks, effect of high tuning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

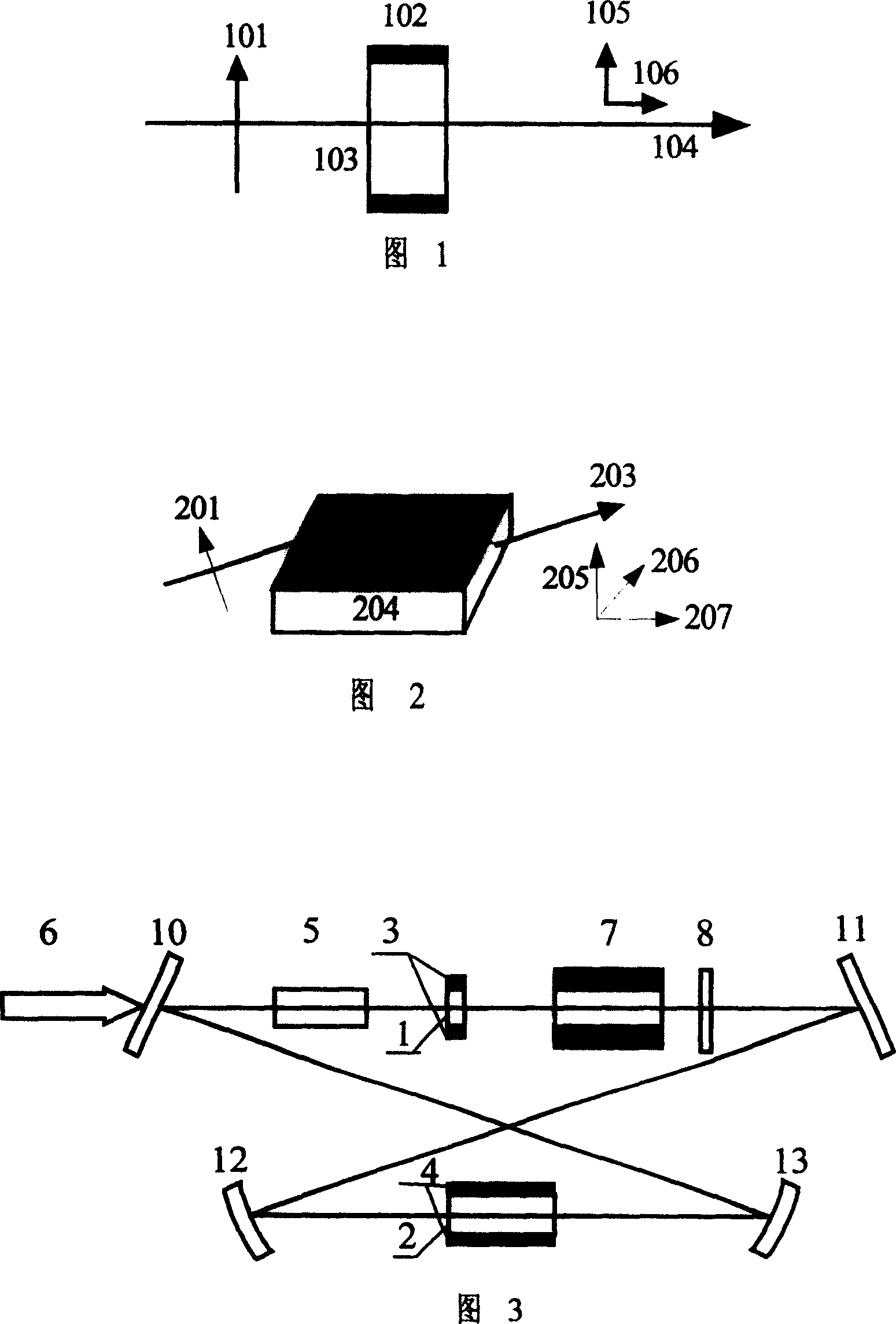

[0034] Embodiment 1. As shown in Fig. 3, the light emitted by the pump source 6 is incident on the gain medium 5 placed in the "8" shaped resonator through the shaping and focusing system. The center wavelength of the light emitted by the pump source 6 and the gain medium The absorption bands of 5 coincide. The resonant cavity is composed of two plane mirrors 10, 11 and two concave mirrors 12, 13. The plane mirror 11 has a transmittance of 4% for the oscillating laser. The two concave mirrors 12, 13 totally reflect the wavelength of the oscillating laser. The plane mirror 10 simultaneously It satisfies the anti-reflection of the pump light and the total reflection of the oscillating laser. Gain medium 5 uses anisotropic crystals, such as Nd:YVO 4 , Nd: YAP, Ti: Sapphire, etc., an oblique angle of 1° is formed between the two transparent surfaces (eliminating the etalon effect). The optical unidirectional device composed of the Faraday rotator 7 and the half-wave plate 8 in the cav...

Embodiment 2

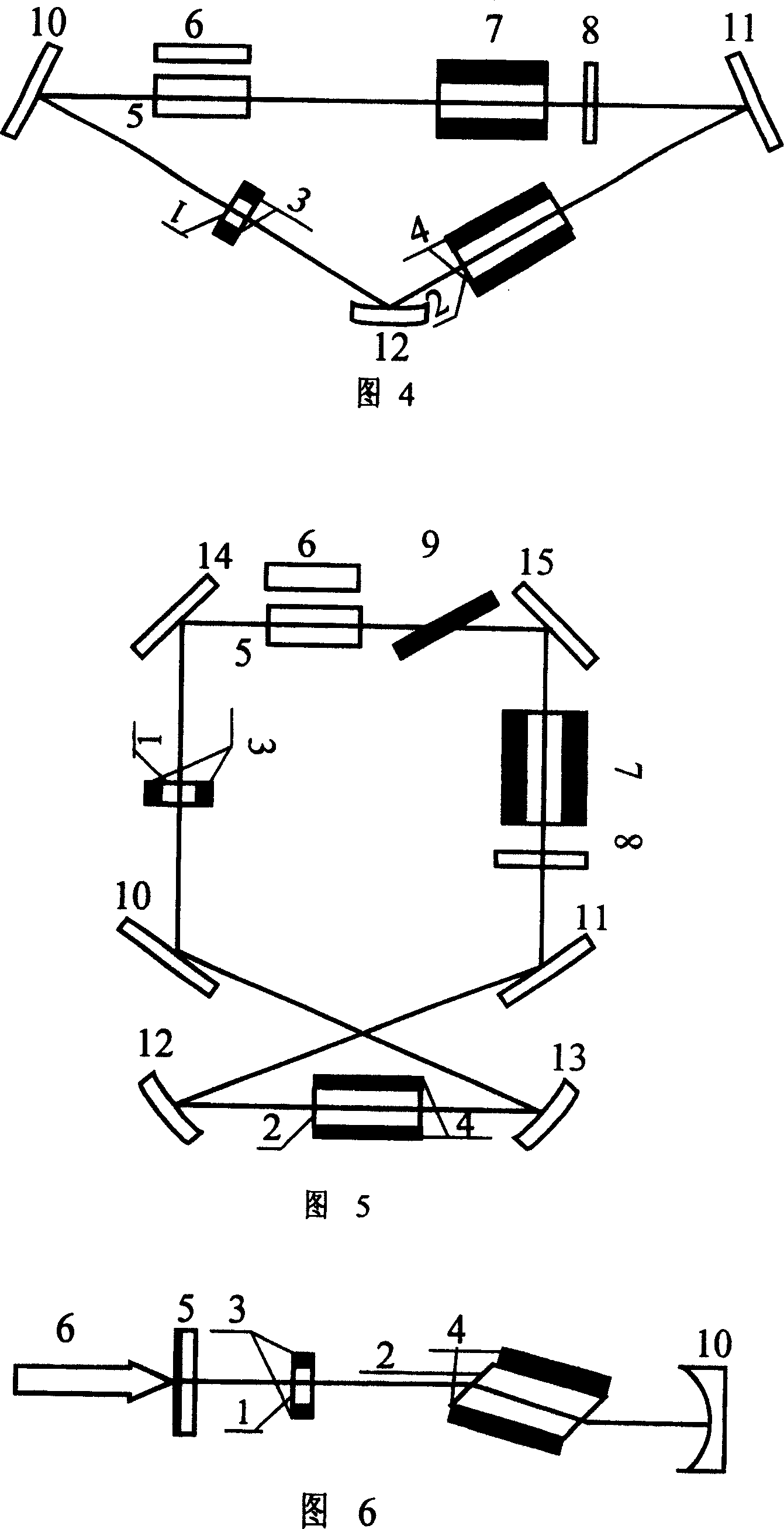

[0035] Example 2. As shown in Figure 4, the pump source 6 placed in the condenser cavity pumps the gain medium 5 placed in the condenser cavity. The gain medium 5 is placed in the optical path of the three-mirror ring resonator. The resonant cavity consists of two Two flat mirrors 10, 11 and a concave mirror 12 are formed together. The flat mirror 10 and the concave mirror 12 are coated with oscillating laser total reflection and pump light anti-reflection film. The flat mirror 11 is an output mirror and is coated with an oscillating laser fixed-point reflection film. Gain medium 5 uses anisotropic crystals, such as Nd:YVO 4 , Nd: YAP, Ti: Sapphire, etc., its two transparent surfaces should be at a certain angle (eliminate the etalon effect). The optical unidirectional device composed of the Faraday rotator 7 and the half-wave plate 8 in the cavity makes the laser operate at a single frequency. The first electro-optic crystal 1 covered with the electrode 3 is placed between the fl...

Embodiment 3

[0036] Embodiment 3. As shown in Fig. 5, the light emitted by the pump source 6 is incident on the gain medium 5 placed in the six-mirror ring resonator through the shaping and focusing system. The center wavelength of the light emitted by the pump source 6 and the gain medium 5 The absorption bands coincide. The resonant cavity is composed of two flat mirrors 10, 11, 14, 15 and two concave mirrors 12, 13. The flat mirrors 10, 11, 14, 15 and the concave mirror 12 are coated with an oscillating laser total reflection film, and the concave mirror 13 is the output mirror , Coated with oscillating laser fixed-point reflective film. The gain medium 5 can use isotropic crystals, such as Nd:YAG, He-Ne gas, etc. Its two light-passing surfaces should be at a certain angle (eliminate the etalon effect). The Brewster window 9 is used as a polarizer, and the optical unidirectional device composed of the Faraday rotator 7 and the half-wave plate 8 in the cavity makes the laser operate at a sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com