Umbrella-shaped enlarger for pile foot and pile body

A technology of expander and pile end, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc. It can solve the problems of underground pipeline damage, small single pile bearing capacity, and uplift of site soil, so as to improve bearing capacity and bearing capacity , Improve the effect of side friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

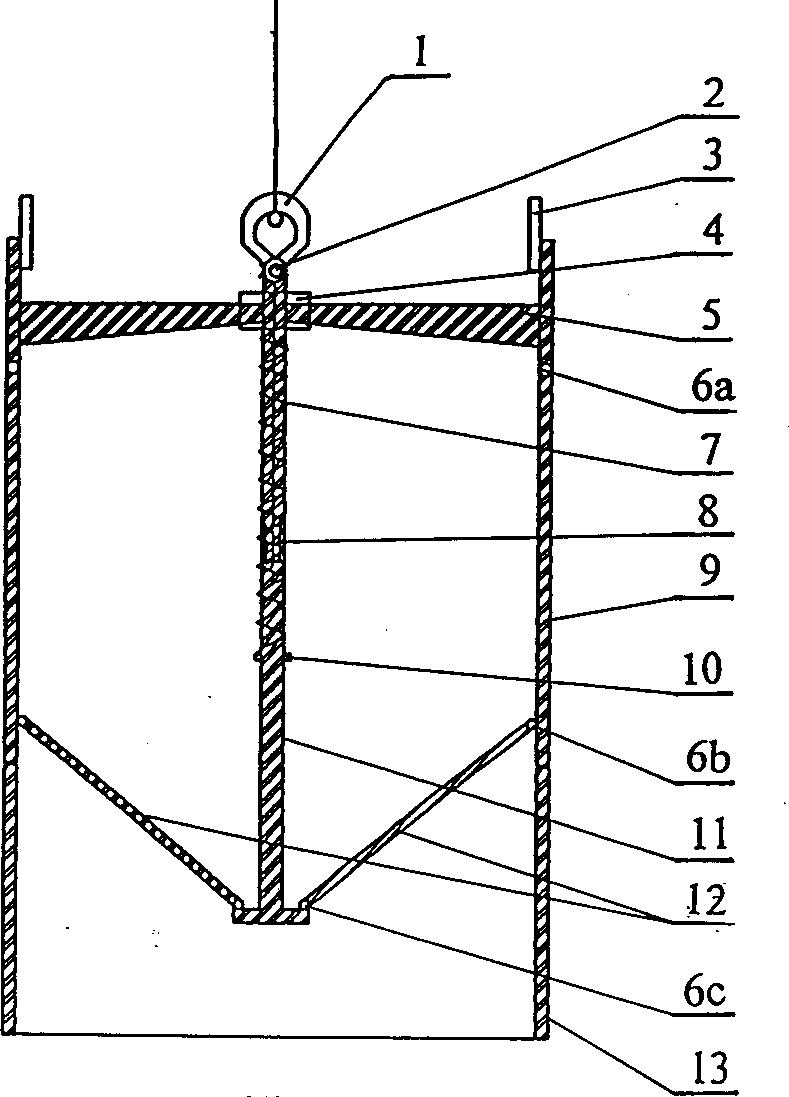

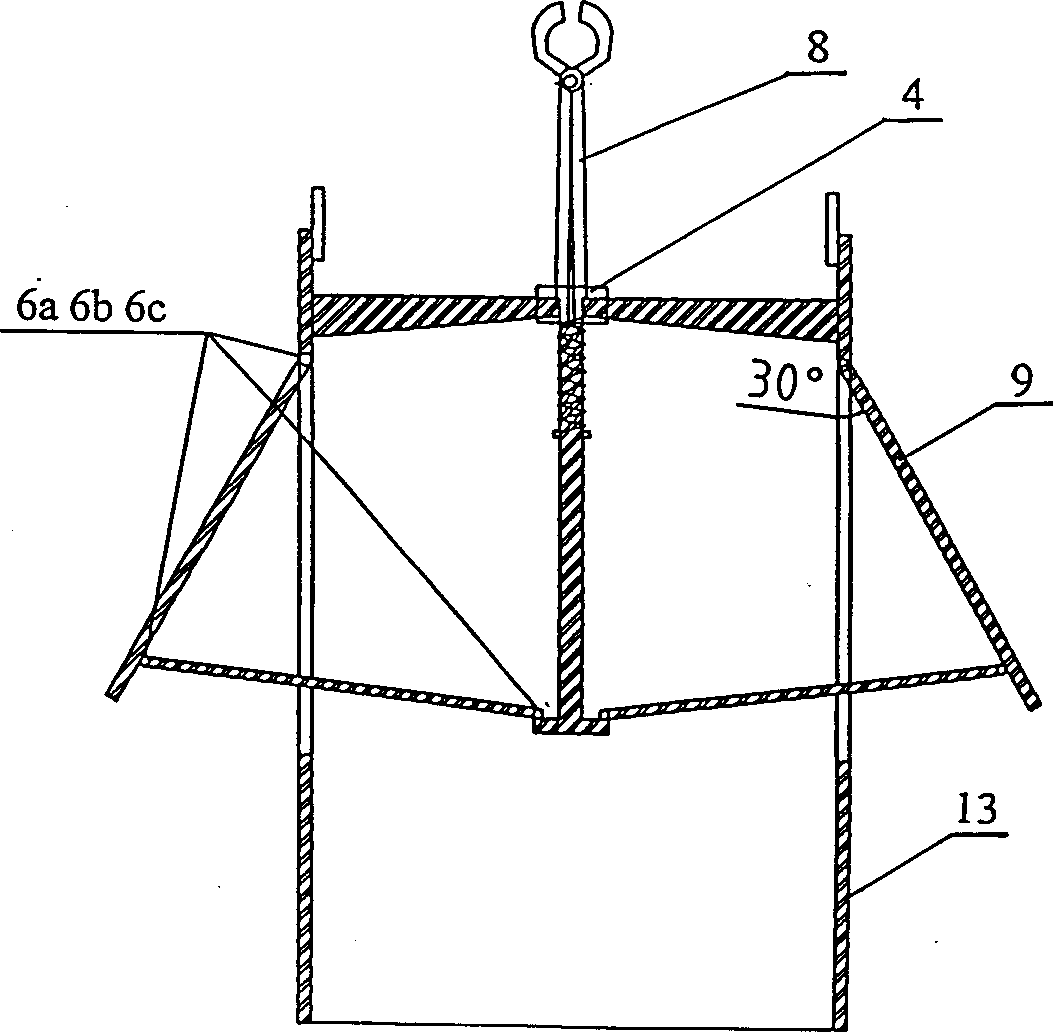

[0017] Such as figure 1 , figure 2 Shown, the concrete structure of the present invention is as follows:

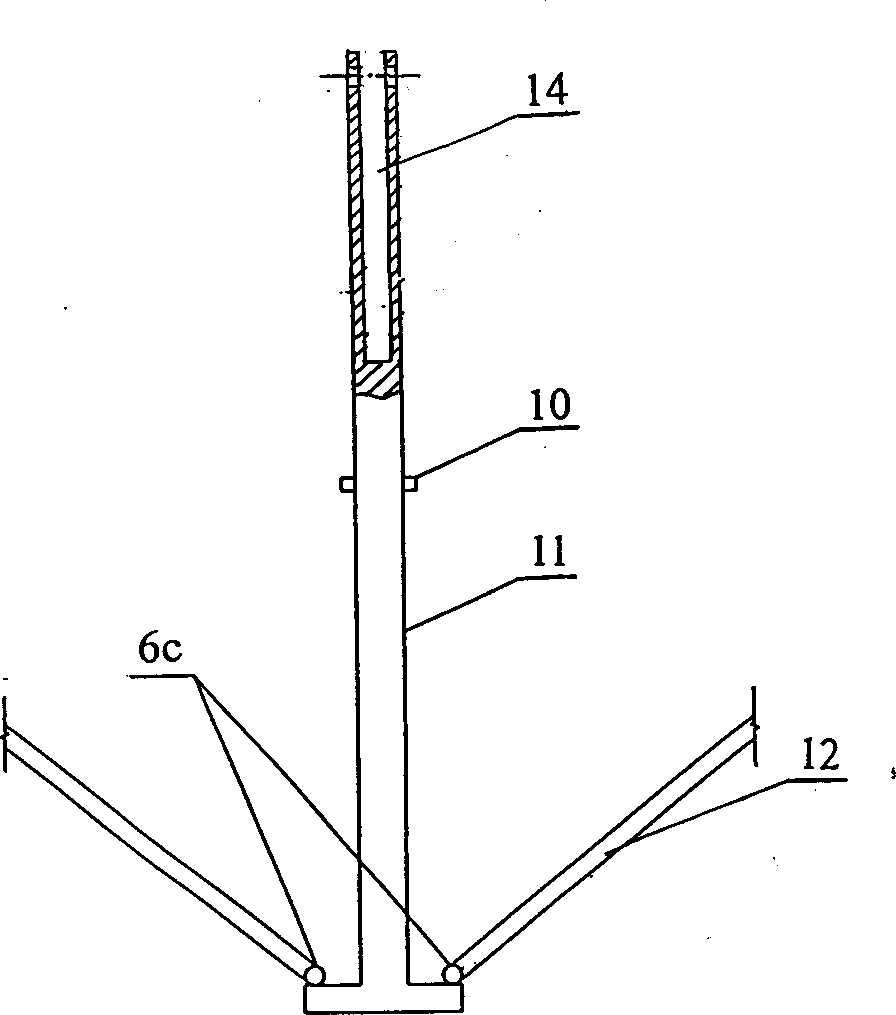

[0018] 1) Cylindrical parts: including the outer sleeve 13 composed of several equally divided movable valves 9 in the middle section of the cylinder wall, the inner wall of the upper end of the outer sleeve 13 is equally welded with several equally divided fan-shaped steel sheets 16 and the restraining disc in the center The fixed end cap 5 composed of 4, the upper end of the movable flap 9 is hinged with the outer sleeve wall with a hinge 6a, the lower end of the movable flap 9 is equipped with a hinge 6b, and there are several equal parts on the inner wall of the outer sleeve 13 above the fixed end cap 5. The inner stopper 3 is used for positioning when connecting with the pile driving steel pipe of the pile driver;

[0019] 2) Umbrella-shaped supporting parts installed in the outer sleeve 13: including dowel bar 11 and several fan-shaped support plates 12, one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com