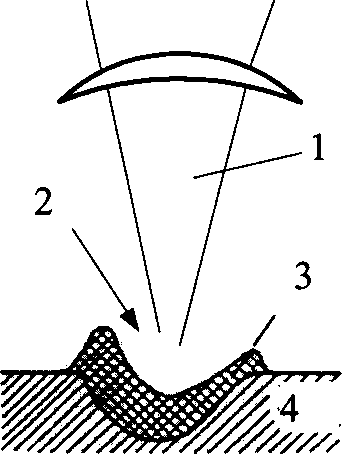

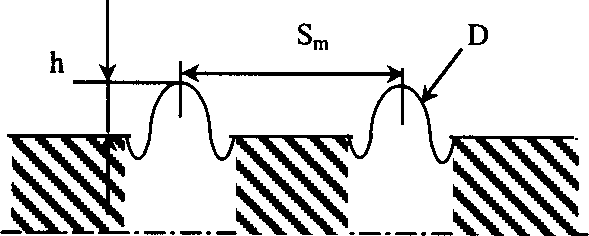

Method for working ball cap convex on roll surface by laser

A roll surface and laser processing technology, which is applied in the field of mechanical processing, can solve the problems that it is difficult to adapt to the roughening requirements of rolling high-quality steel plates, cannot accurately control the shape and roughness of the roll surface, and cannot form a convergent oil wedge effect. Achieve good adhesion and appearance quality, good microscopic image clarity, prevent scratches and adhesion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Laser texturing of high-carbon chromium bearing steel GCr15 roll sample The sample is cylindrical, with a diameter of 17 mm and a thickness of 6 mm. The material is GCr15, and the specific chemical composition is shown in Table 1. After overall quenching, the surface hardness reaches HV 935, and the surface roughness after grinding is Ra=0.04μm.

[0021] Table 1 Chemical composition of GCr15

[0022] Chemical composition (%) GCr15 C: 0.95~1.05, Mn: 0.25~0.45, Si: 0.15~0.35, P: ≤

[0023] 0.025, S: ≤0.025, Cr: 1.40~1.65

[0024] The specific processing steps are as follows:

[0025] (1) Use a pulsed Nd:YAG laser with a wavelength of 1.06 μm to roughen the roll, and install the roll sample to be processed on the work table;

[0026] (2) Select laser single pulse energy as 25J, pulse width as 0.5ms, and modify the laser pulse waveform;

[0027] (3) Adjust the focus position to the top of the roll surf...

Embodiment 2

[0034]The laser textured sample of the high-carbon chromium bearing steel GCr15 roll sample is cylindrical, with a diameter of 17mm and a thickness of 6mm. The material is GCr15, and the specific chemical composition is shown in Table 1. After overall quenching, the surface hardness reaches HV 935, and the surface roughness after grinding is Ra=0.04μm.

[0035] The specific processing steps are as follows:

[0036] (1) Use a pulsed Nd:YAG laser with a wavelength of 1.06 μm to roughen the roll, and install the roll sample to be processed on the work table;

[0037] (2) Choose laser single pulse energy as 5J, pulse width as 0.05ms, and carry out the laser pulse waveform as follows image 3 The reshaping treatment shown;

[0038] (3) Adjust the focus position to the top of the roll surface, so that the laser beam is defocused and irradiated on the roll surface, and the defocus amount is 0.5 mm;

[0039] (4) Choose pulse frequency 100Hz, laser scanning speed 50mm / s;

[0040] (...

Embodiment 3

[0044] The laser textured sample of the high-carbon chromium bearing steel GCr15 roll sample is cylindrical, with a diameter of 17mm and a thickness of 6mm. The material is GCr15, and the specific chemical composition is shown in Table 1. After overall quenching, the surface hardness reaches HV 935, and the surface roughness after grinding is Ra=0.04μm.

[0045] The specific processing steps are as follows:

[0046] (1) Use a pulsed Nd:YAG laser with a wavelength of 1.06 μm to roughen the roll, and install the roll sample to be processed on the work table;

[0047] (2) Choose laser single pulse energy as 100J, pulse width as 5ms, and carry out the laser pulse waveform as follows image 3 The reshaping treatment shown;

[0048] (3) Adjust the focus position to the top of the roll surface, so that the laser beam is defocused and irradiated on the roll surface, and the defocus amount is 3.9mm;

[0049] (4) Choose pulse frequency 50Hz, laser scanning speed 25mm / s;

[0050] (5)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com