Selective hydrogenization catalyst and its preparing method and use

A technology of selective hydrogenation and catalyst, applied in the field of selective hydrogenation catalyst and its preparation and application, which can solve the problems of poor hydrogenation selectivity, low catalyst hydrogenation activity, and large amount of green oil generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Add 0.6ml of copper nitrate solution containing 10mg / mlCu and 0.85ml of palladium nitrate solution containing 4.7mg / mlPd into a beaker, then add 6.8ml of water, mix well, adjust the pH of the solution to 1.2 with nitric acid and ammonia water, and prepare Dipping solution. Take 20g of the same carrier as in Comparative Example 1 and put it into a 100ml beaker, add the prepared impregnating solution, impregnate the carrier, then dry at 120°C for 8 hours, decompose at 450°C in an air atmosphere to obtain the 2-1 catalyst, and use a scanning electron microscope to determine the catalyst 90% of the palladium and silver are distributed in the catalyst body from the surface of the carrier to a depth of 500-1000 microns.

Embodiment 2

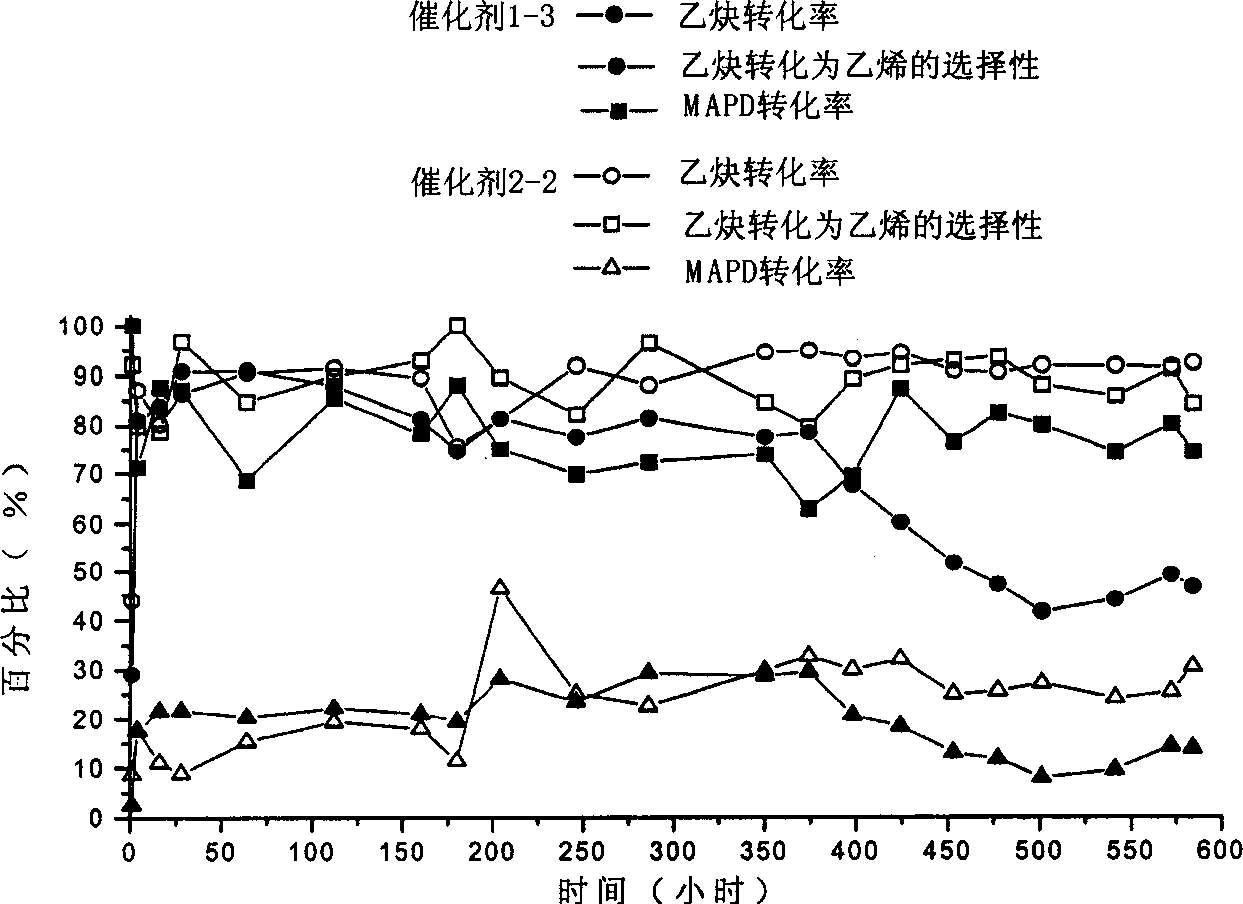

[0057] Add 1.0ml of silver nitrate solution containing 10mg / mlAg and 0.85ml of palladium nitrate solution containing 4.7mg / mlPd into a beaker, then add 5.5ml of water, mix well, adjust the pH of the solution to 1.2 with nitric acid and ammonia water, and prepare Dipping solution. Take 20g of the same carrier as in Comparative Example 1 and put it into a 100ml beaker, add the prepared impregnating solution, impregnate the carrier, then dry at 120°C for 8 hours, decompose at 450°C in an air atmosphere to obtain the 2-2 catalyst, and use a scanning electron microscope to determine the catalyst 90% of the palladium and silver are distributed in the catalyst body from the surface of the carrier to a depth of 500-1000 microns.

Embodiment 3

[0059] Add 3.9ml of gold chloride solution containing 4.8mg / mlAu and 0.85ml of palladium nitrate solution containing 4.7mg / mlPd in the beaker, then add 2.5ml of water, after mixing thoroughly, adjust the pH of the solution to 1.2 with nitric acid and ammonia water, Prepared as a dipping solution. Take 20 g of the same carrier as Comparative Example 1 and put it into a 100ml beaker, add the prepared impregnating solution, impregnate the carrier, then dry it at 120°C for 8 hours, and decompose it in an air atmosphere at 450°C to obtain the 2-3 catalyst, which is measured by scanning electron microscopy. 90% palladium and silver of the catalyst are distributed in the catalyst body from the surface of the carrier to a depth of 500-1000 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com