Efficient liquid-phase conic chromatographic column

A technology of high performance liquid chromatography and liquid chromatography, which is applied in the field of high performance liquid chromatography columns, and can solve the problems of not having a tapered high performance liquid chromatography preparation column, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

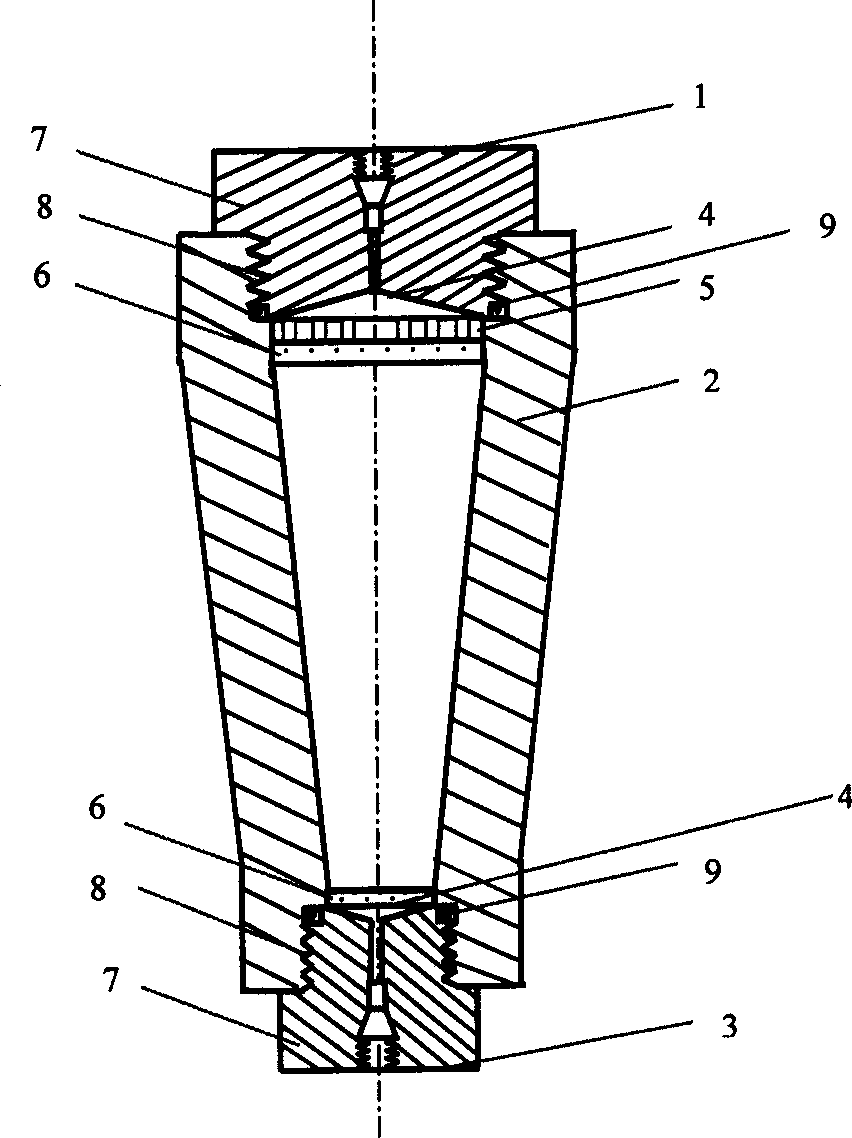

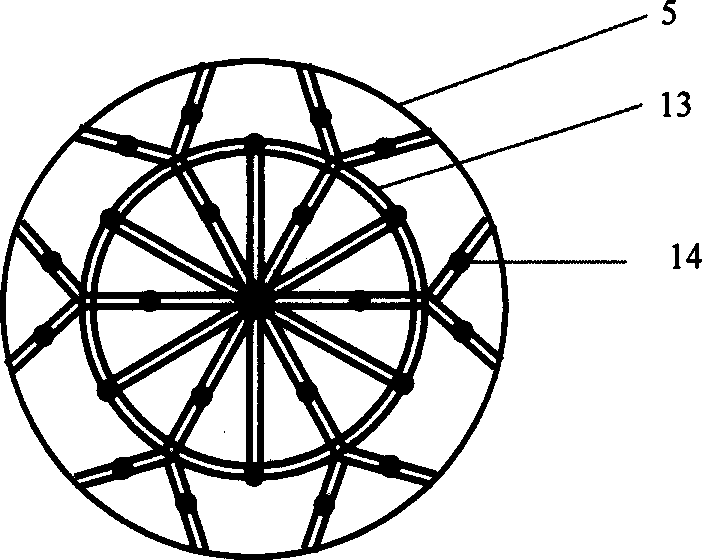

[0019] Example 1: The inner diameter of the inlet of the conical liquid chromatography preparative column is 20 mm, the inner diameter of the outlet is 7 mm, and the length is 5 cm. according to figure 1 The two ends of the column shown are bolt-type column head 1 and column tail 3, which are matched with the upper and lower ends of the column body 2 with thread 8 and nut 7 respectively; the inner surfaces of column head 1 and column tail 3 are concave into tapered guide grooves 4; O-ring 9, distribution plate 5, porous sieve plate 6 under column head 1; O-ring 9 and porous sieve plate 6 above column tail 3. according to image 3As shown, on the upper part of the distribution plate 5, there is a concentric circular liquid flow collection channel at 3 / 5 of the radius, and there are 12 radial liquid flow channels in the circle, and there is a seepage hole in the center of every other channel, without seepage. The channel of the liquid hole is divided into two channels at the i...

Embodiment 2

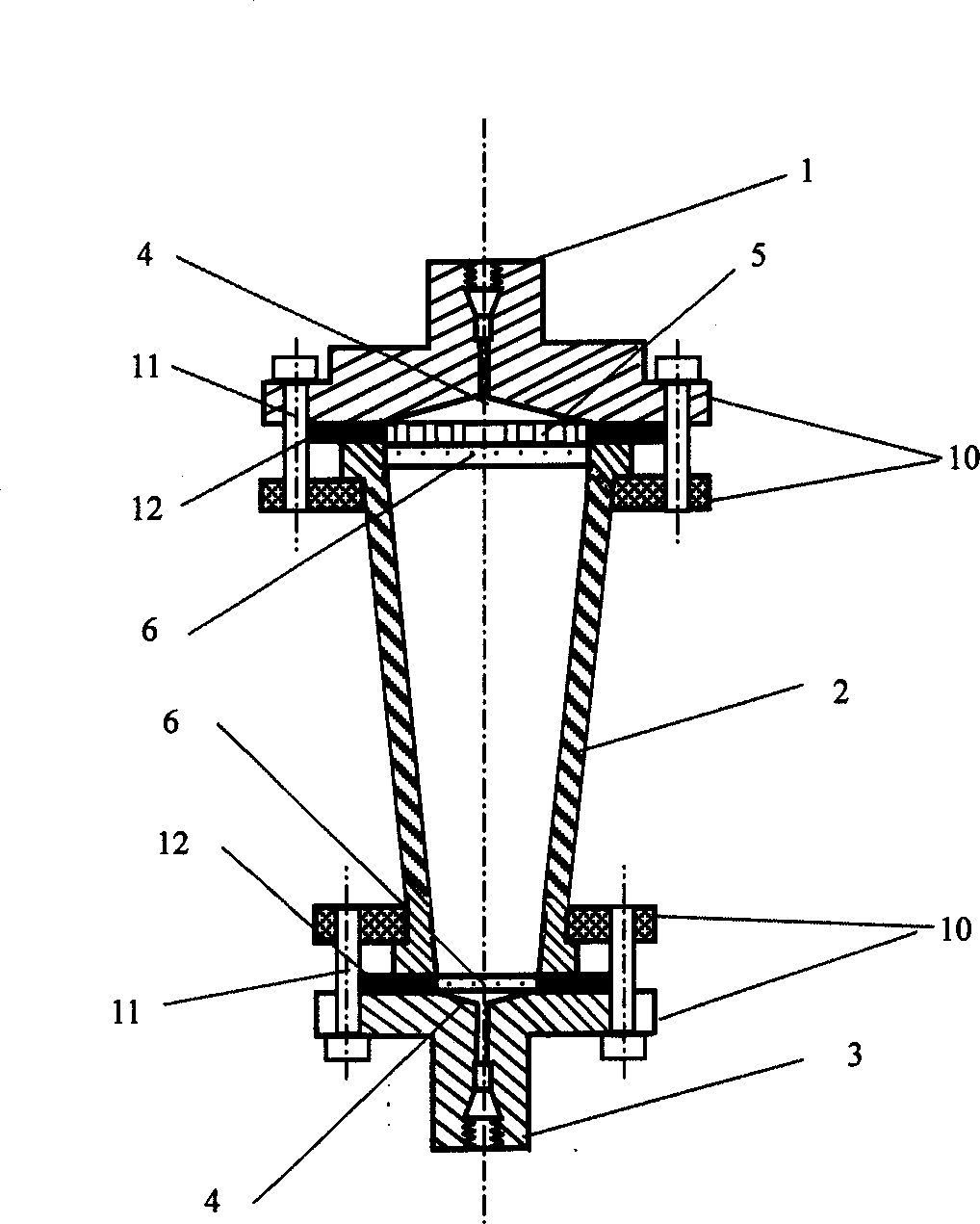

[0022] Example 2: The inner diameter of the inlet of the conical liquid chromatography preparative column is 800 mm, the inner diameter of the outlet is 280 mm, and the length is 25 cm. according to figure 2 The two ends of the shown cylinder 2 are respectively equipped with a column head 1 and a column tail 3 composed of flanges 10; the flange 10 is fastened by bolts 11, and there is a sealing washer 12 in the middle, and the inner surfaces of the column head 1 and the column tail 3 are concave into cones. There is a distribution plate 5 and a porous sieve plate 6 below the column head 1; a porous sieve plate 6 is arranged above the column tail 3. according to image 3 As shown, when the inner diameter 2R of the cylinder inlet is relatively large, the number of seepage holes and concentric circles can be increased as required, or any other form of distribution plate can be used. The function of the distribution plate is to distribute the sample evenly over the entire colum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com