Method for cleaning main carrier

A carrier and cleaning technology, which is applied in the manufacture of record carriers, accessories of record carriers, refurbishment/cleaning record carriers, etc., can solve the problems that it is difficult to completely remove signal pattern foreign objects, it is difficult to make reliable discs, and attachments cannot be removed, so as to prevent Deterioration of transcription signal, improvement of reliability, effects of reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

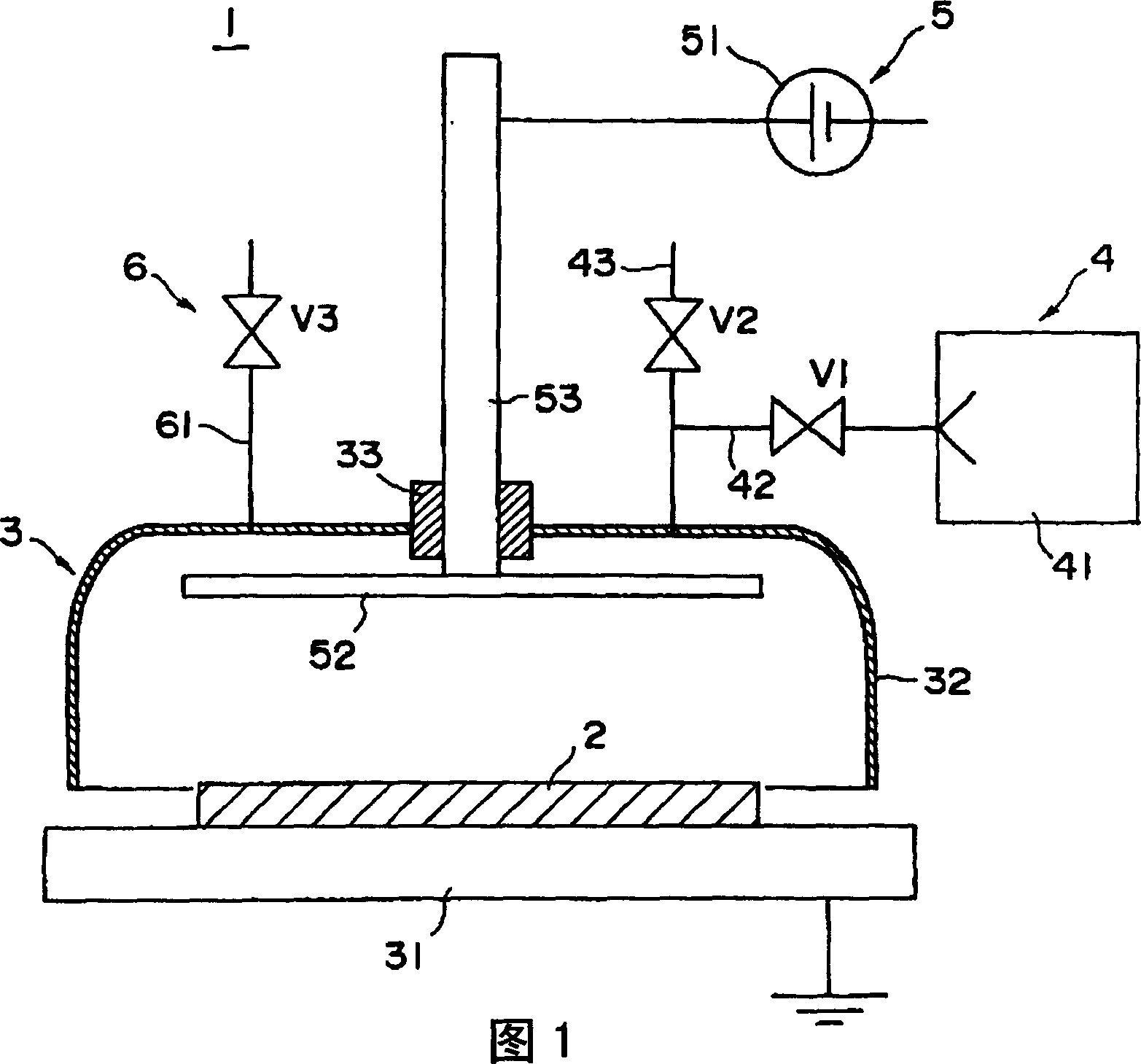

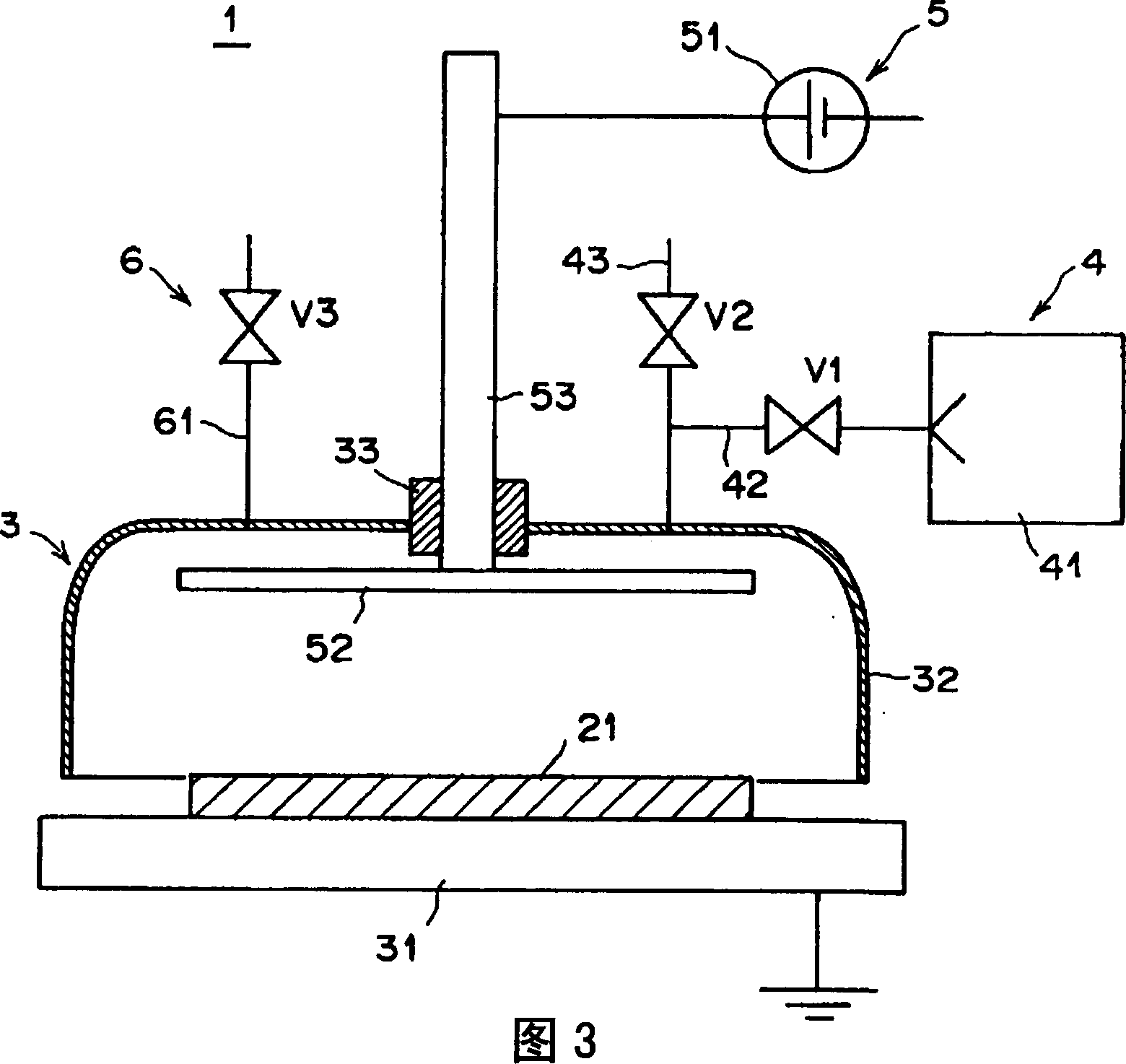

[0039] Next, each embodiment of the present invention will be described in detail. FIG. 1 is a schematic structural view of a cleaning device implementing a cleaning method according to an embodiment.

[0040] The cleaning device shown in Fig. 1 comprises: the decompression container 3 (vacuum container) that accepts main carrier 2; Make the decompression device 4 of decompression in container 3; A discharge device 5 for plasma discharge; a gas introduction device 6 for introducing reactive gas into the container 3 .

[0041] In addition, the cleaning method using the device 1 is to non-contactly remove the attached material on the surface of the main carrier 2 for magnetic transcription or optical disk before performing magnetic transcription or optical disk molding in a dry process using reactive plasma etching. The method of attaching things. That is, a reactive gas is introduced under a reduced pressure state, followed by discharge, and the deposits on the surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com