Active catalyst for docomposing organic waste

A technology of organic waste and catalyst, which is applied in the field of bioengineering, can solve the problems of low active ingredients, long production cycle, and environmental pollution, and achieve the effect of high organic content, simple production method, and small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

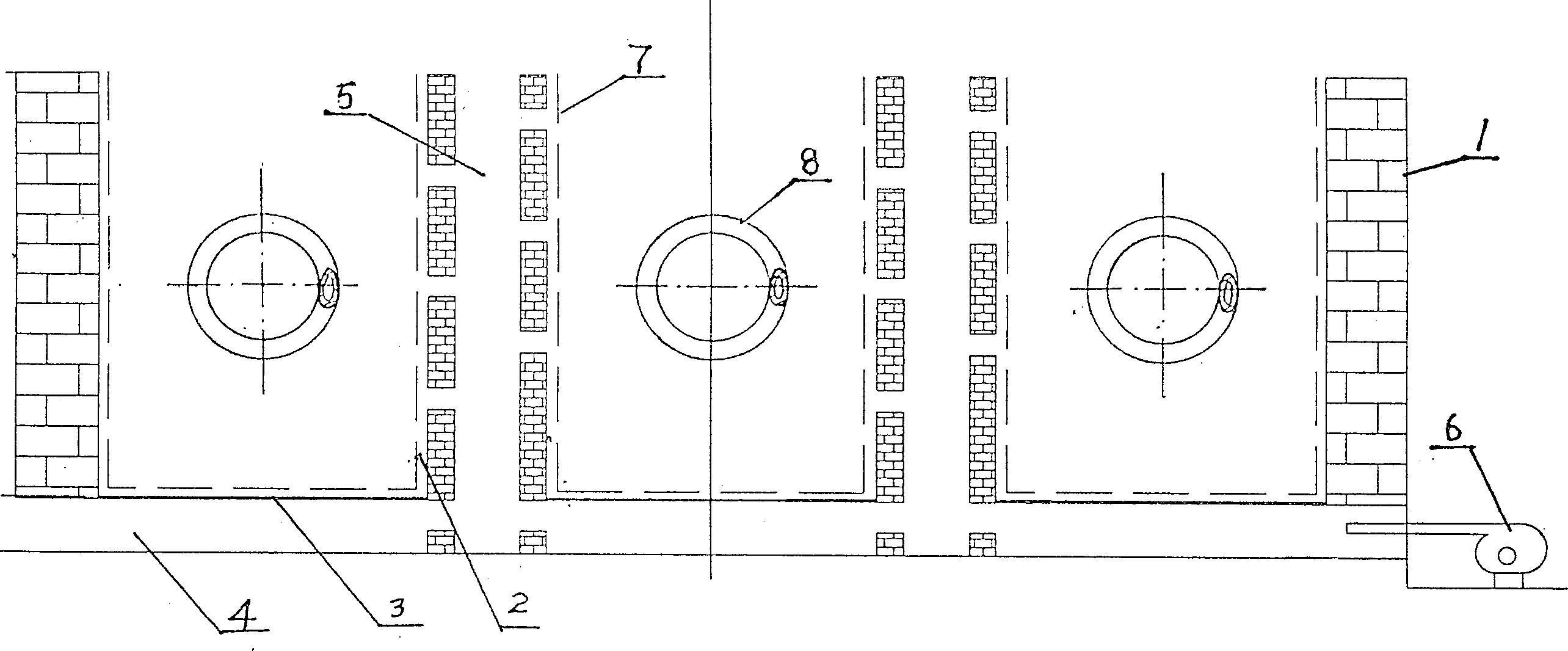

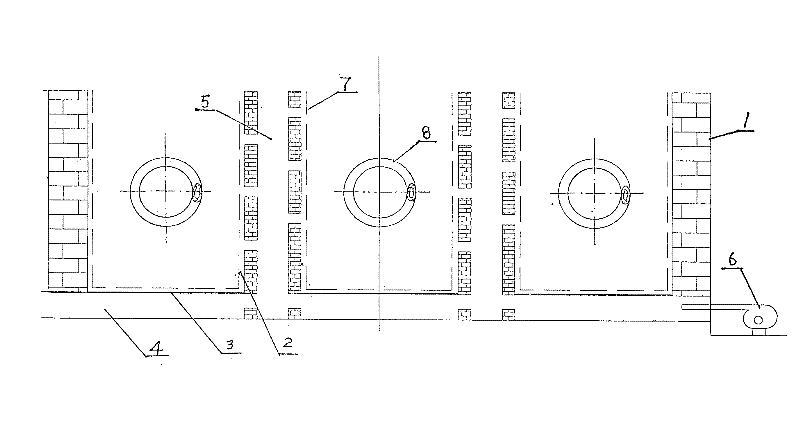

[0019] to combine figure 1 The reactor shown is a box or pool (1) type, with a gap (2) left on the inner wall, and a groove (not shown in the figure), and an overhead support (3) at the bottom, generally 30- 40 cm, the bottom has a drainage vent (4) that communicates with the ventilation box (5) in the reactor, and there are evenly distributed small holes on the wall of the ventilation pipe, the vent is connected with the fan (6), and the inner wall and the bracket and the ventilation pipe The top is evenly covered with bamboo strip mats with air holes in the inside. In the above reactor, first add waste pomace, nut shells and melon seeds, and the ratio is 100kg of mixture of 1:5:0.5. Put 40kg of water into the reactor and pile it with raw materials. The material layer is covered with plastic film. Temperature, when the temperature in the stacking reaction process shows a downward trend, drop to 40°C to take out the material, crush it, and then put the crushed material into t...

Embodiment 2

[0021] With the reactor of embodiment 1, get waste pomace, nut shell and melon seed, its proportioning is 5: 3: 2 mixed material 100kg, then get urea 0.3kg and be dissolved in 30kg water earlier and then add in the reactor and raw material heap The material layer is covered with plastic film, and the temperature of the material is 55°C. The exudate from the lower part of the suction reactor is circulated and sprayed back to the material, and the temperature is adjusted by strong ventilation from the ventilation pipe. When the temperature of the material reaction process is declining , down to 50°C, take out the material, crush it, then put the crushed material into the reactor for secondary stacking, add 15kg of water, when the stacking temperature is 60°C, stir and mix with a road mixer and cool down until Below 50°C, take out the material, dry and sieve to get -5mm catalyst, add 10kg for open-air composting to produce fertilizer, and add -1mm for human and livestock manure to...

Embodiment 3

[0023] With the reactor of embodiment 1, get waste pomace, nut shell and melon seed, its proportioning is that 100kg of the mixture of 10:0.5:5 is packed in the reactor, then 0.1kg urea is dissolved in 20 parts of water and adds reaction Stacking in the reactor, the material layer is covered with plastic film, the stacking temperature is 60°C, the seepage at the bottom of the reactor is sucked and circulated back to spray the stacking, and the temperature is adjusted by forced ventilation from the ventilation pipe in the reactor. The temperature of the material reaction process shows a downward trend. When the temperature drops to 40°C, the material is taken out and crushed. When the temperature is lowered until the temperature drops below 50° C., the materials are taken out, dried and sieved to obtain a catalyst with a particle size of -5 mm. For open-air composting to produce fertilizer, add 10kg, and -1mm for human and animal manure to produce fertilizer, add 9kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com