Method and apparatus for particle agglomeration

A technology of particle and ion generator, applied in electrostatic coagulator, a device for condensing particles in gas flow, and promoting the field of small particle coagulation in gas flow, which can solve the problems of increasing equipment size, polluting waste water, and low particle collection efficiency. To achieve the effect of promoting cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Description of preferred embodiments

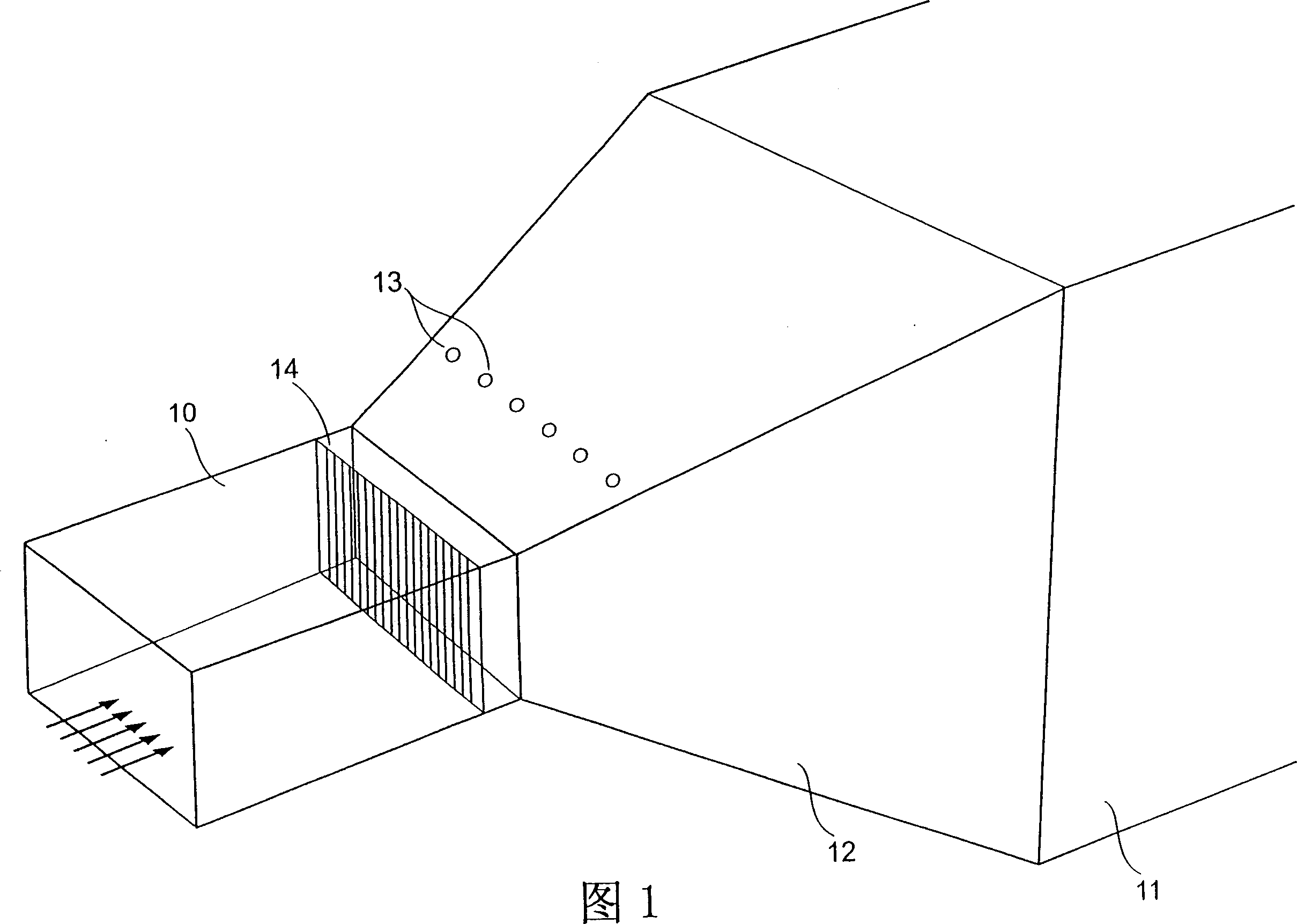

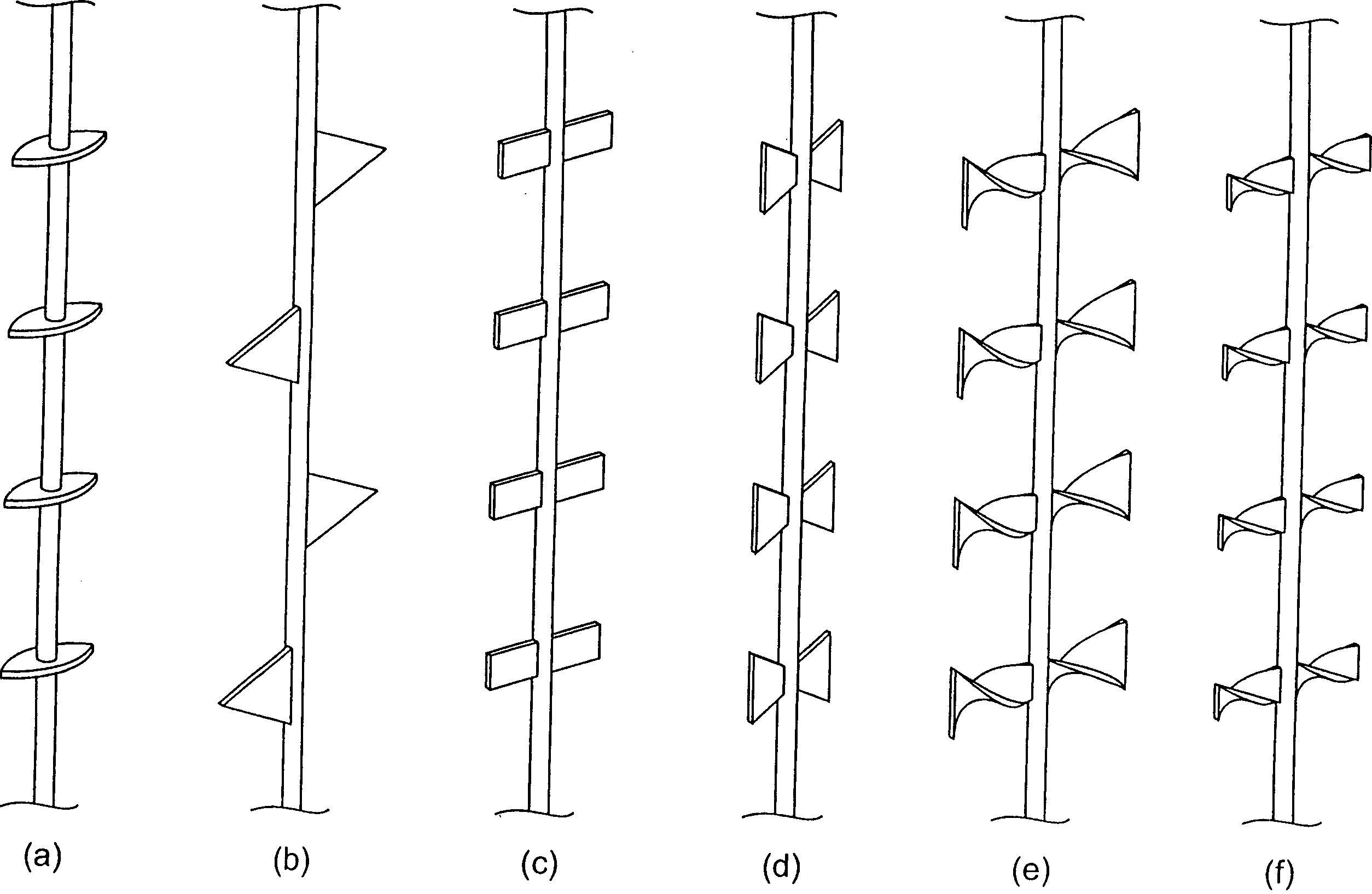

[0042] Figures 1-3 show the first embodiment of the particle aggregation device of the present invention. In this embodiment, pre-charged particles of different sizes in the air stream are made to have different velocities in order to improve the mixing of the particles in the longitudinal direction of motion. This increased mixing leads to agglomeration of particles.

[0043] As shown in Figure 1, a pipe 10 with a substantially constant cross section is connected to a second pipe 11. The cross section of the second pipe 11 is substantially constant and much larger than the cross section of the pipe 10. The pipe 10 passes through a cross section. The gradually increasing Evasé part 12 is connected to the pipe 11. The pipes 10, 11, 12 provide an air duct for gas flow.

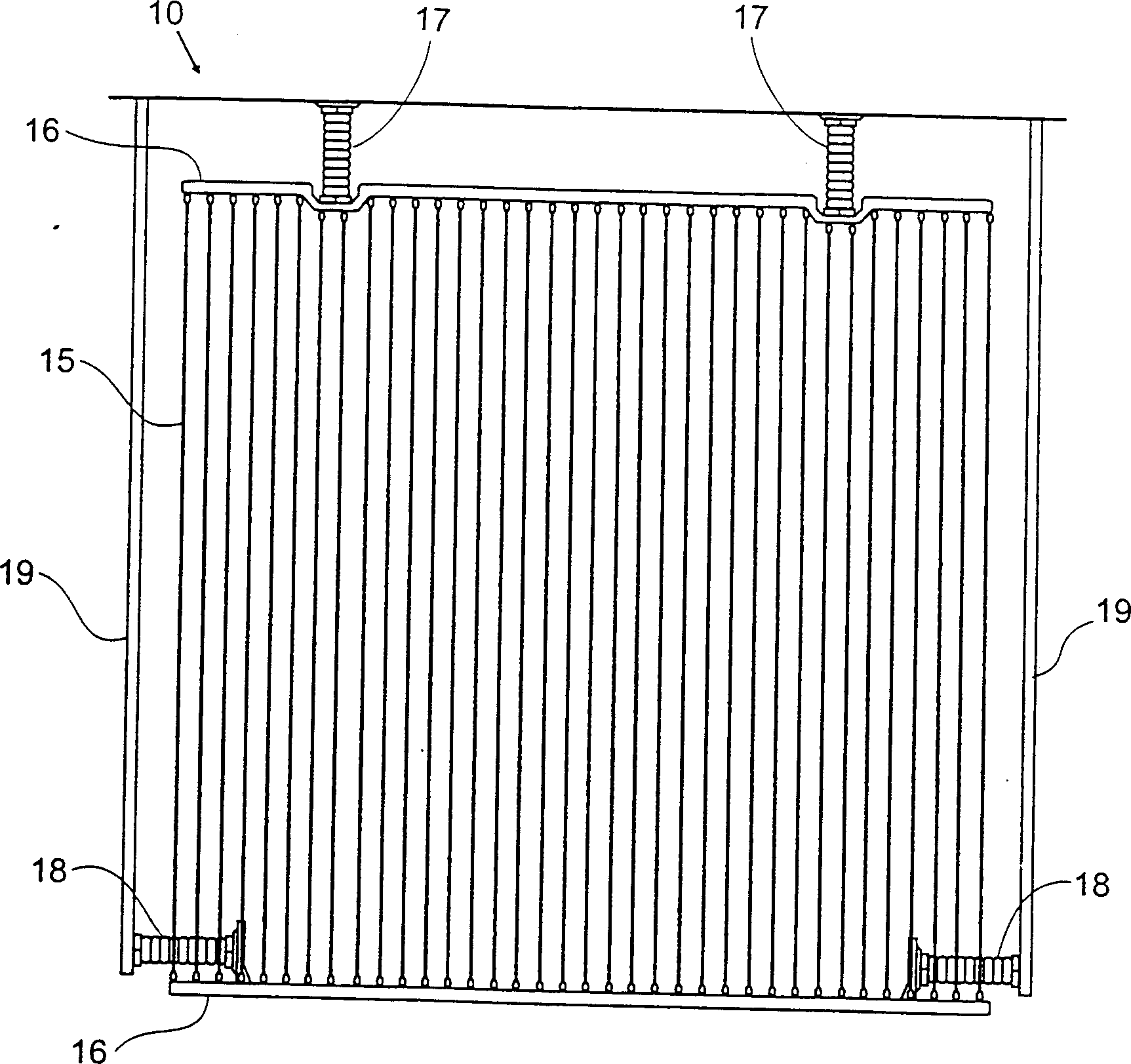

[0044]An AC ionizer 14 is provided in the pipe 10 to charge particles in the gas stream. The AC ionizer 14 is shown schematically in the form of a block in FIG. 1 and sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com