Degradable flat fibre bundle and its preparing process

A flat and fiber technology, applied in the field of degradable fiber preparation, can solve the problems of insufficient dyeing performance, poor wet elasticity, and poor monofilament strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

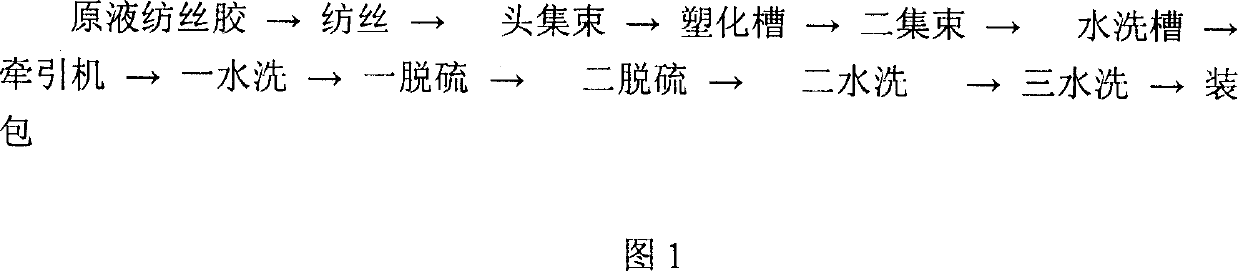

[0012] The flat and degradable long-bundle fiber is made of cotton pulp or wood pulp or their mixture through alkalization and yellowing to form cellulose xanthate to form dope spinning glue, and then go through the following processes: dope spinning glue, spinneret spinning Yarn, head clustering, plasticizing tank plasticization, secondary cluster drafting, water washing tank, traction machine, first washing, first desulfurization, second desulfurization, second washing, finished product packaging.

[0013] The main process parameters are as follows:

[0014] 1. Pulp: single cotton pulp or wood pulp can be used as raw material, and the following ratio can also be used: cotton pulp: wood pulp = 7-3: 3-7, and there is no difference in process conditions within this range. The process of alkalization and yellowing to make cellulose xanthate is as follows: This is a conventional process: alkalization uses one dipping, the concentration of dipping alkali is 228-230g / l, and the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com