Optical record medium

A technology for optical recording medium and recording layer, which is applied in the direction of optical recording carrier, optical recording carrier manufacturing, data recording, etc., and can solve the problems of small unevenness and inability to obtain sufficient recording characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The following examples will be used to further describe the present invention in detail, but the present invention is not limited by these examples. [Example 1] (production of optical recording medium)

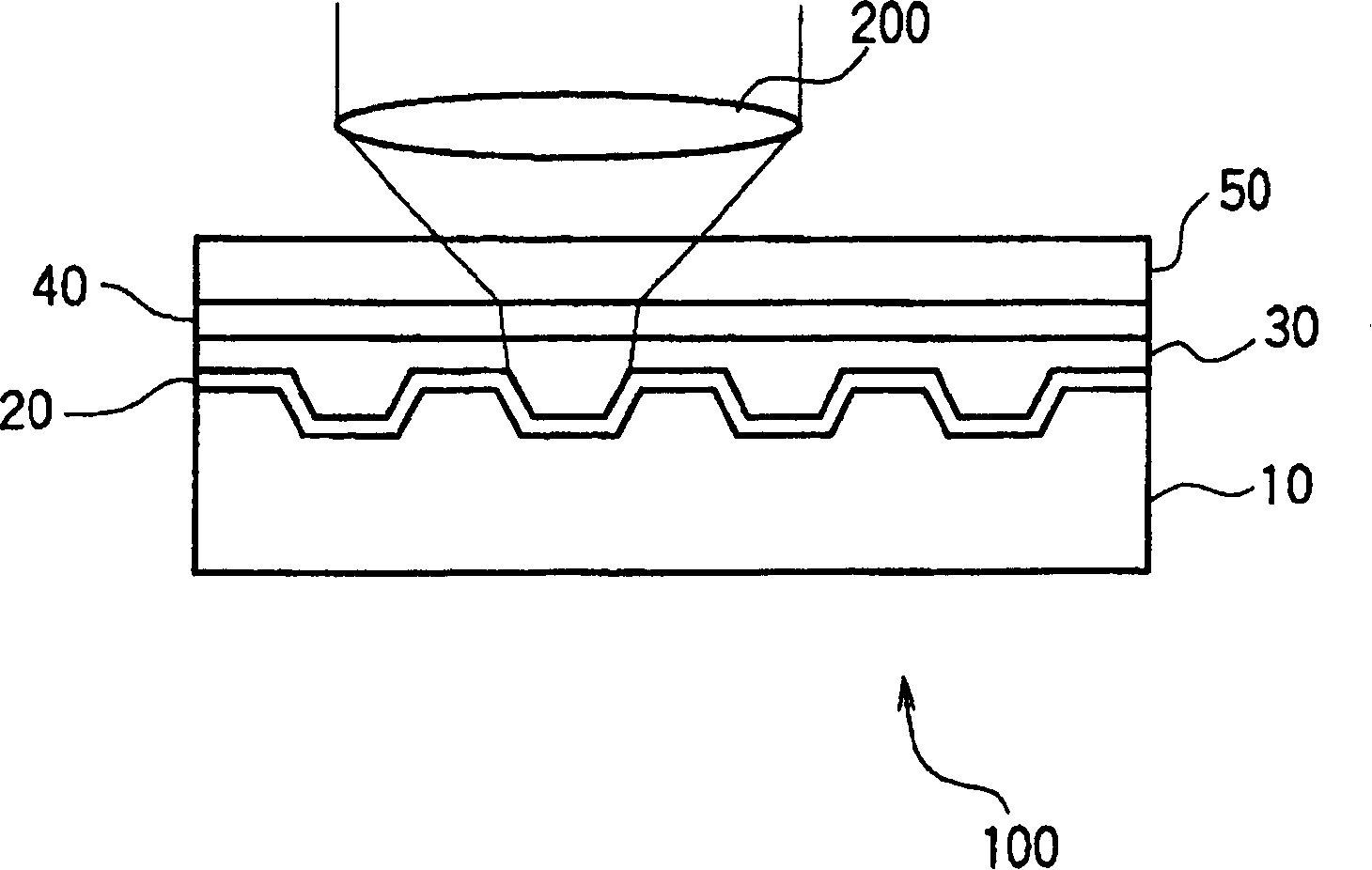

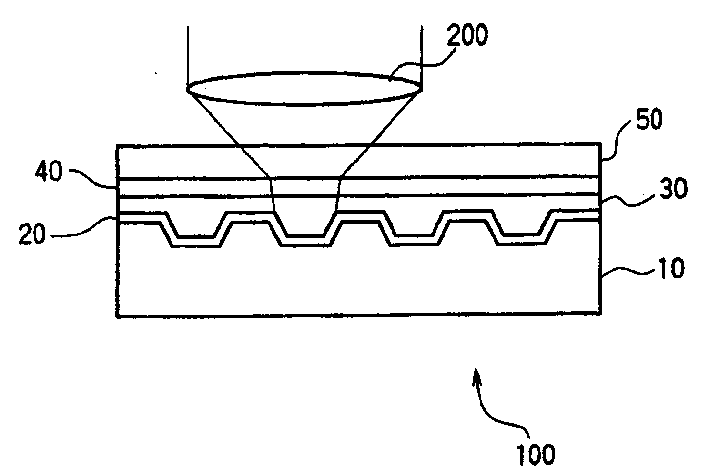

[0064] Injection molding polycarbonate resin (polycarbonate produced by Teijin Corporation, trade name: PanriteAD5503) substrate, which has a spiral groove (depth 100nm, width 0.120 μm, track pitch 0.3 μm), thickness 1.1 mm, diameter 120 mm. Ag was sputtered on the grooved surface of the obtained substrate to form a 100 nm thick light reflection layer.

[0065] Then, 2 g of phthalocyanine-based organic compound A (maximum absorption: 340 nm) was mixed in 148 ml of 2,2,3,3-tetrafluoropropanol, and subjected to ultrasonic treatment for 2 hours to dissolve it to prepare a coating for forming a recording layer. cloth liquid. Under the conditions of 23° C. and 50% RH, the prepared coating solution was applied on the light reflection layer by a spin coating method while cha...

Embodiment 2

[0073] In Example 1, the optical recording medium of Example 2 was produced in the same manner as in Example 1 except that the cyanine-based organic compound B (absorption wavelength: 373 nm) was used instead of the phthalocyanine-based organic compound A.

[0074] The same test as in Example 1 was carried out on the prepared optical recording medium to evaluate recording characteristics. The results are shown in Table 1. [Example 3]

Embodiment 3

[0075] In Example 1, the optical recording medium of Example 3 was produced in the same manner as in Example 1, except that the aminobutadiene-based organic compound C (absorption wavelength: 359 nm) was used instead of the phthalocyanine-based organic compound A.

[0076] The same test as in Example 1 was carried out on the prepared optical recording medium to evaluate recording characteristics. The results are shown in Table 1. [Example 4)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com