Small mechanical variable laser strength attenuator

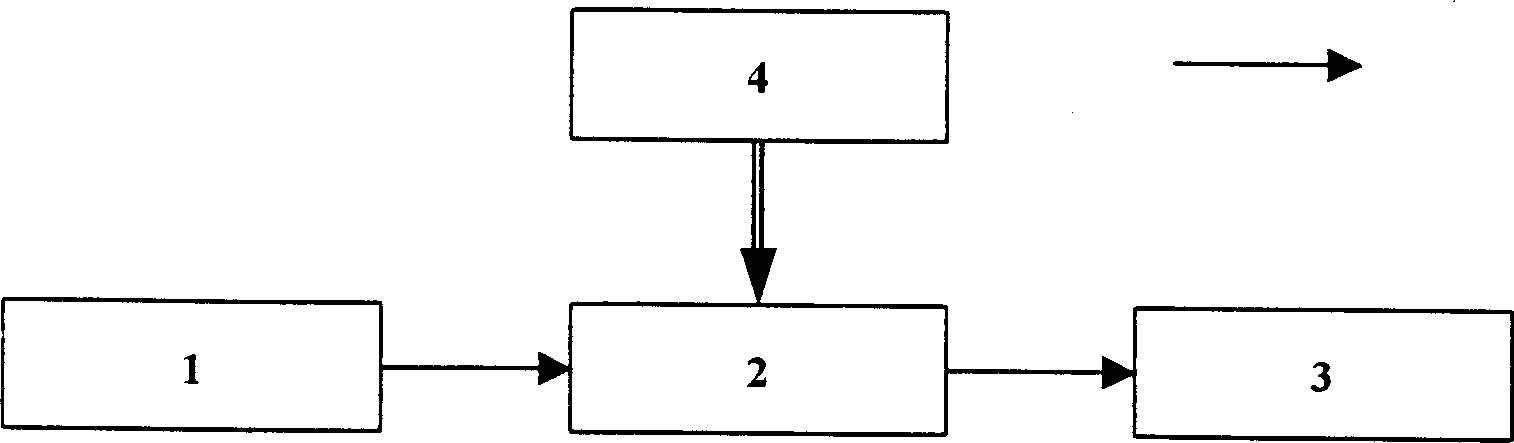

A light intensity attenuation, mechanical technology, applied in lasers, laser parts, optics, etc., can solve the problems of not very large adjustable range of light intensity attenuation, difficult to achieve mass production, complex film production process, etc. Wide working wavelength range, no transmission loss, low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

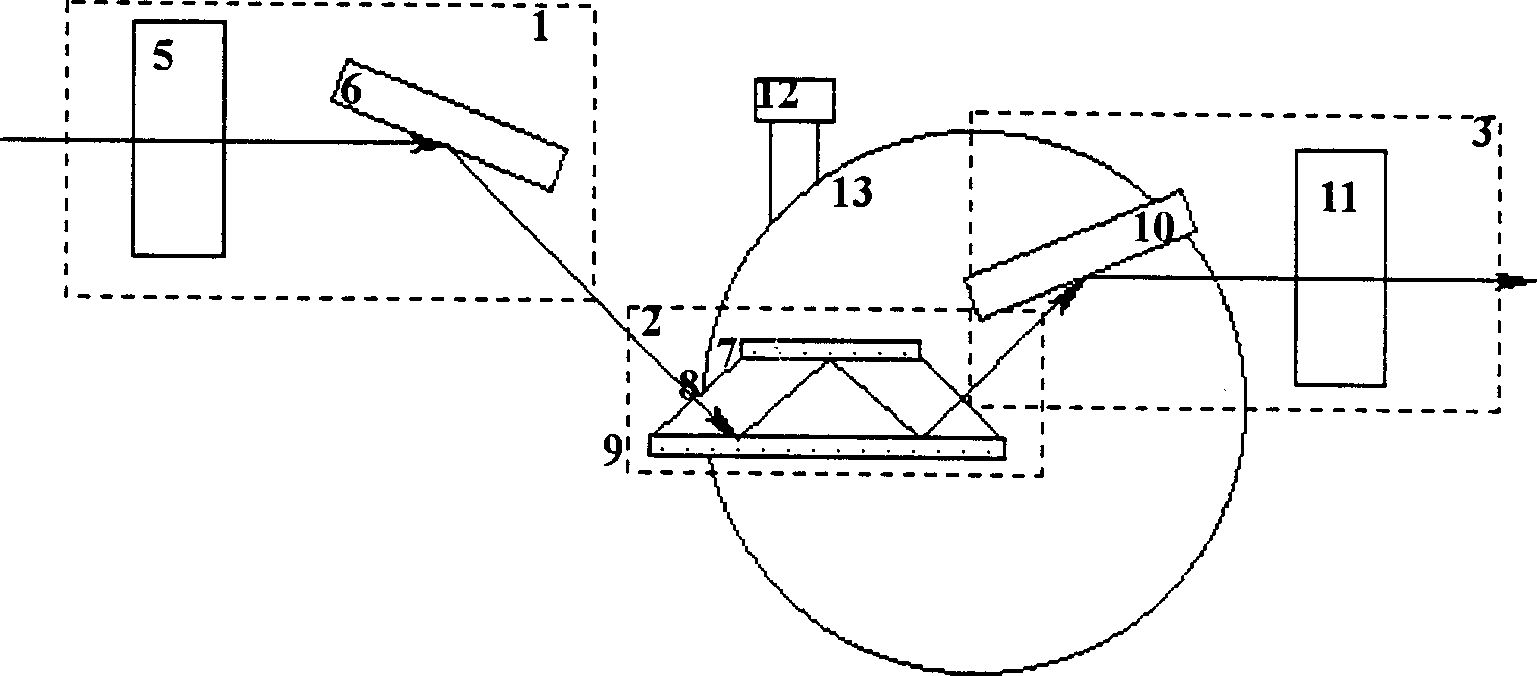

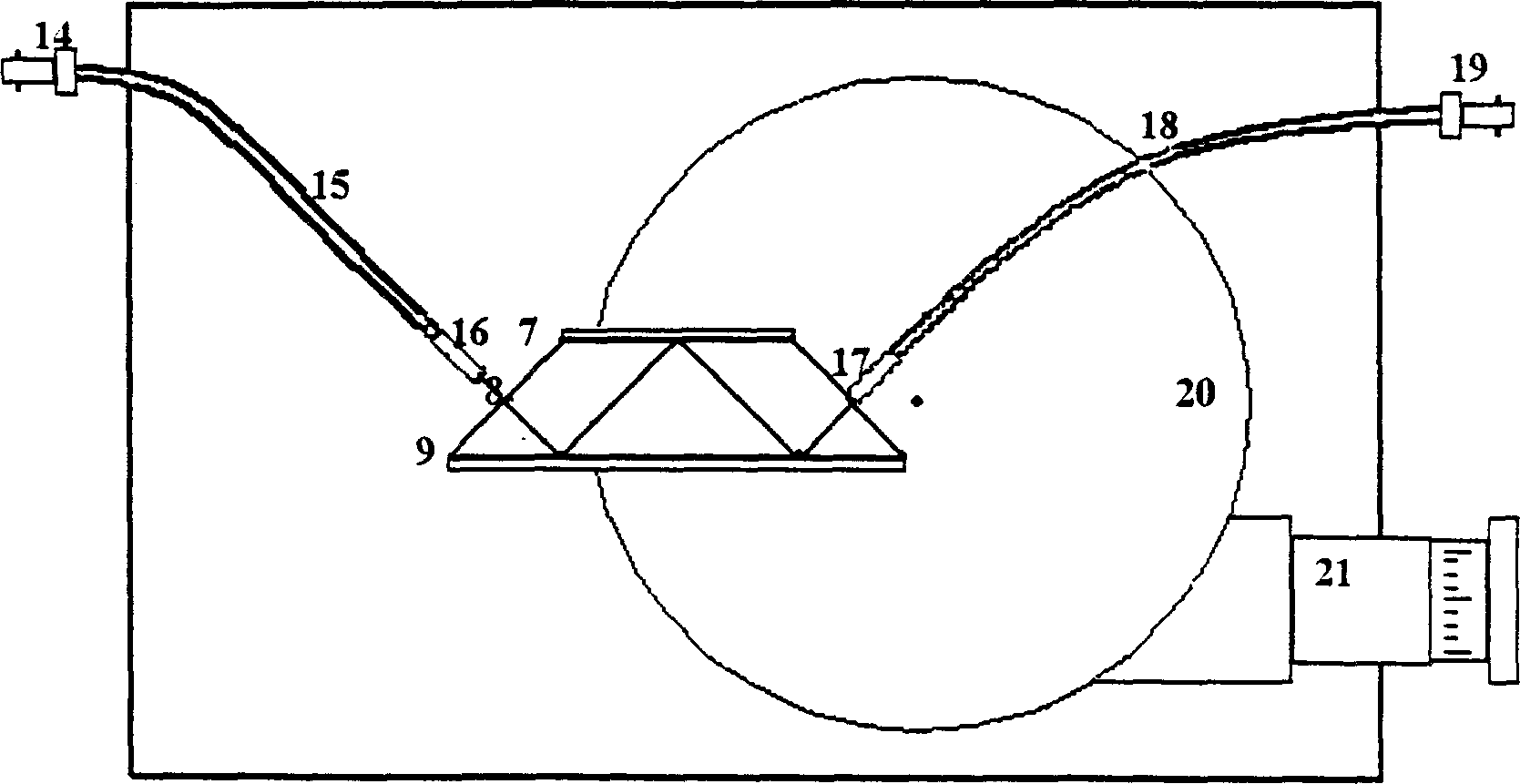

[0023] Embodiment 1: Taking the light intensity attenuator with optical fiber connector as an example, the optical input part is composed of optical fiber connector 14, optical fiber 15 and optical fiber self-focusing lens 16. The standard optical fiber connector 14 can be easily connected with the input light, such as a pigtailed fiber The output laser is connected in the form of optical fiber, and the self-focusing lens 16 keeps the light parallel, and the light is incident on the light intensity attenuation device 2 from the light input part 1 in a fixed direction.

[0024] The light intensity attenuation device 2 is composed of an isosceles trapezoidal prism 8, an upper dielectric film 7, and a lower dielectric film 9. The parameter design of the light intensity attenuation device 2 takes 1.3 μm as the center wavelength. If other wavelengths are selected as the working wavelength, the parameter design needs to be redesigned. optimization. In the light intensity attenuation...

Embodiment 2

[0027] Embodiment 2: Taking a large-aperture laser light intensity attenuator as an example, the light input part 2 is composed of an incident window 23 , a collecting lens 24 and a plane mirror 25 . The collecting lens 24 keeps the light rays parallel. The plane mirror 25 changes the direction of light propagation, so that the reflected output light and input light are kept in a straight line.

[0028]The light intensity attenuation device 2 is composed of an isosceles trapezoidal prism 8, an upper dielectric film 7, and a lower dielectric film 9. The parameter design of the light intensity attenuation device 2 takes 1.3 μm as the center wavelength. If other wavelengths are selected as the working wavelength, the parameter design needs to be redesigned. optimization. In the light intensity attenuation device 2, the prism 8 is an isosceles trapezoidal prism with high refractive index (ZF7, n=1.750, base angle 38.45°), and the upper and lower bottom dielectric films 7 and 9 us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com