Cascade superhigh temperature water source heat pump apparatus

A water source heat pump and ultra-high temperature technology, which is applied in heating devices, heat pumps, geothermal power generation, etc., can solve the problems of energy efficiency ratio of only about 1.5, water temperature that cannot meet the requirements, and high condensation pressure, so as to reduce pipeline specifications and pump energy delivery , Good water supply temperature and high water supply temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will now be described in further detail with reference to the drawings.

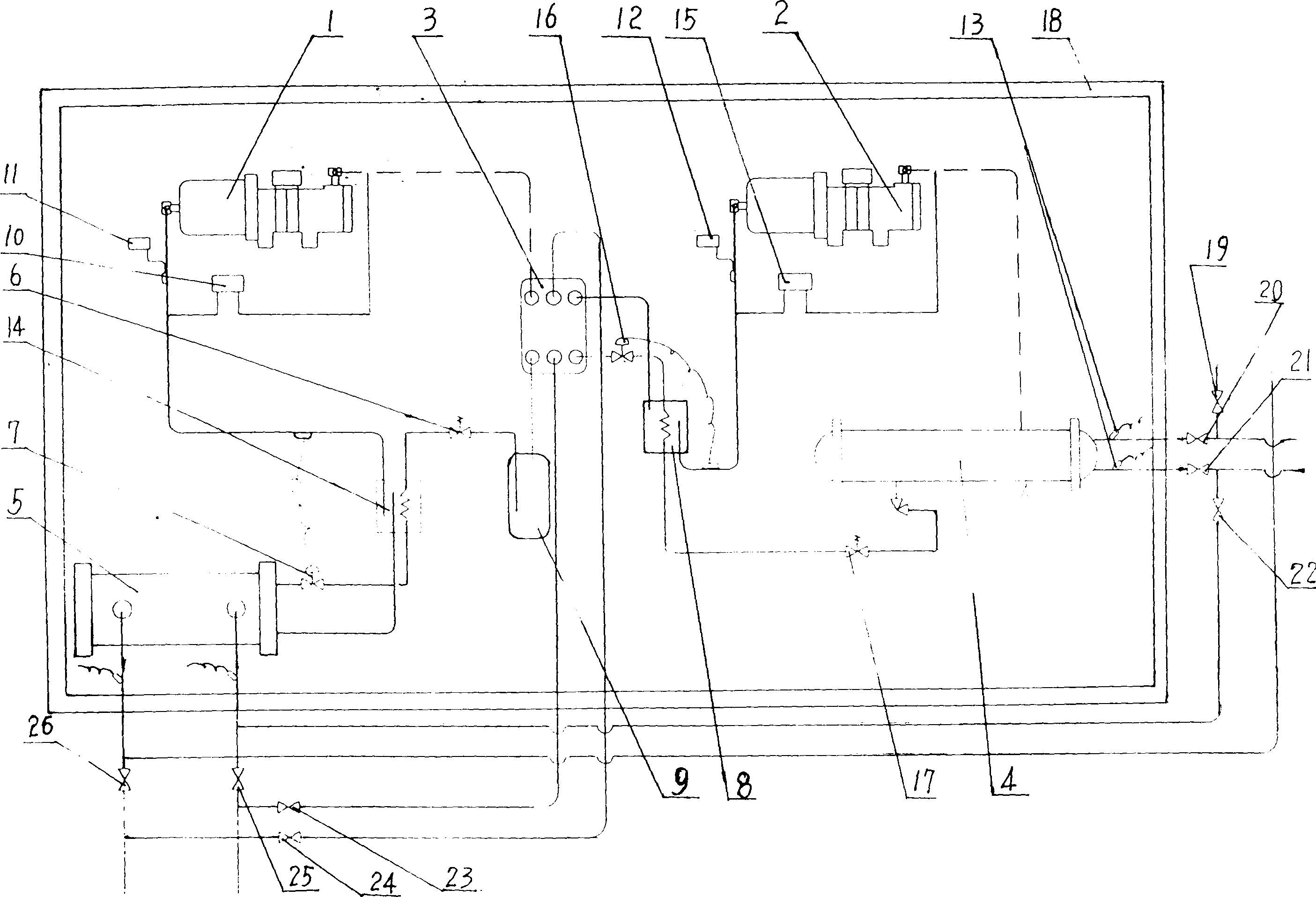

[0018] figure 1 This is a specific embodiment of the present invention: the device cabinet 18 is equipped with an evaporator 5, and the medium output port of the evaporator 5 is connected with the medium inlet of the low-temperature vapor-liquid heat exchanger 14 by a copper pipe. The medium outlet of the low-temperature vapor-liquid heat exchanger 14 is connected with the medium inlet of the low-temperature compressor 1 by a copper pipe. A temperature switch 11 is installed on the copper pipeline connecting the vapor-liquid heat exchanger 14 and the low-temperature compressor 1, and one end of the low-temperature high-low pressure controller 10 is also installed on this pipeline. The medium output port of the low-temperature compressor 1 is connected to the low-temperature medium input port of the evaporative condenser 3 by a copper pipe. The low-temperature medium output port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com