Positive electrode material of alkaline battery and its preparation method

A cathode material, alkaline battery technology, applied in the direction of alkaline storage battery electrodes, alkaline storage batteries, electrode manufacturing, etc., can solve the problems of unsatisfactory storage performance of alkaline batteries, long production process routes, unsatisfactory storage performance, etc. Excellent high-load discharge characteristics and durability, the effect of solving self-discharge and large discharge current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

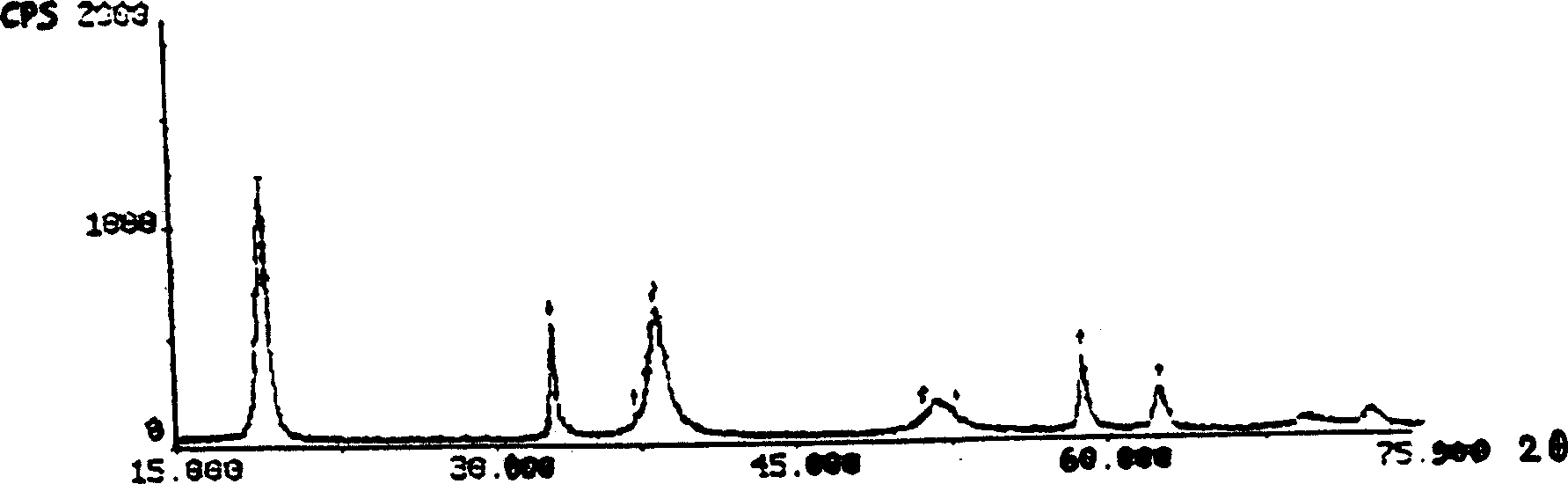

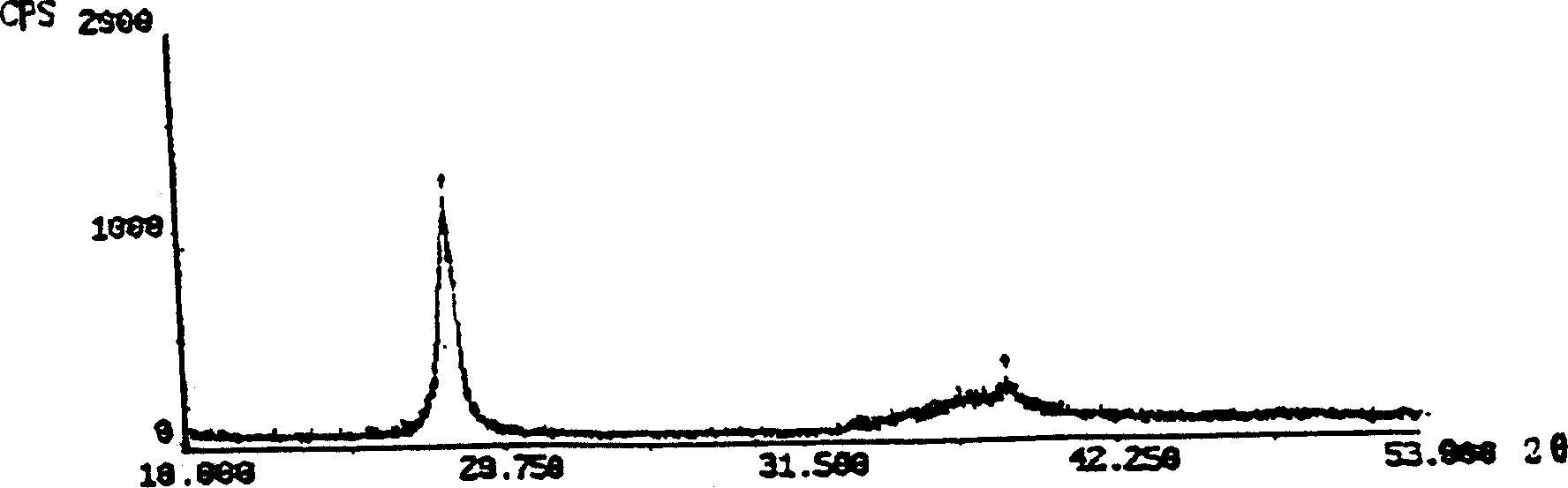

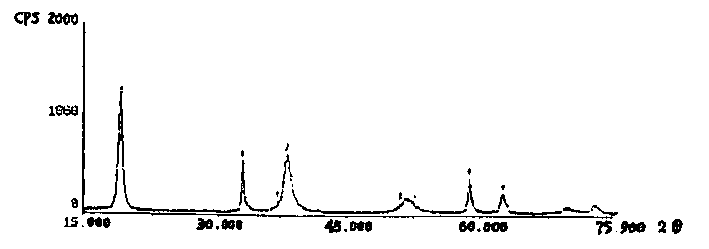

Image

Examples

Embodiment Construction

[0015] A positive electrode material for alkaline batteries, the positive electrode material is a kind of β-nickel zinc oxyhydroxide containing nickel and zinc hydroxides in the form of eutectic on the crystal lattice, and has the following molecular formula: β-Ni (1-X) Zn X O (1-X) (OH) (1+X) , Where the number of moles of X is greater than or equal to 2% but less than or equal to 20%, due to the introduction of zinc-containing hydroxide, on the crystal lattice of β-nickel oxyhydroxide, it will increase the oxygen reaction of β-nickel oxyhydroxide The oxygen overpotential can satisfactorily inhibit or greatly slow down the oxygen evolution reaction of β-nickel oxyhydroxide, and better solve the self-discharge defect of β-nickel oxyhydroxide. Therefore, one of the alkaline batteries involved in the present invention is used. The positive electrode material β-nickel zinc oxyhydroxide is the positive electrode, zinc is the negative electrode, and the concentrated alkali solution is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com