Metal halide lamp

A metal halide lamp and halide technology, applied in the field of light-emitting tubes, can solve the problems of large changes in lamp color temperature and decrease in beam maintenance rate, and achieve the effects of increasing lamp life, suppressing the decrease in beam maintenance rate, and improving lamp efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

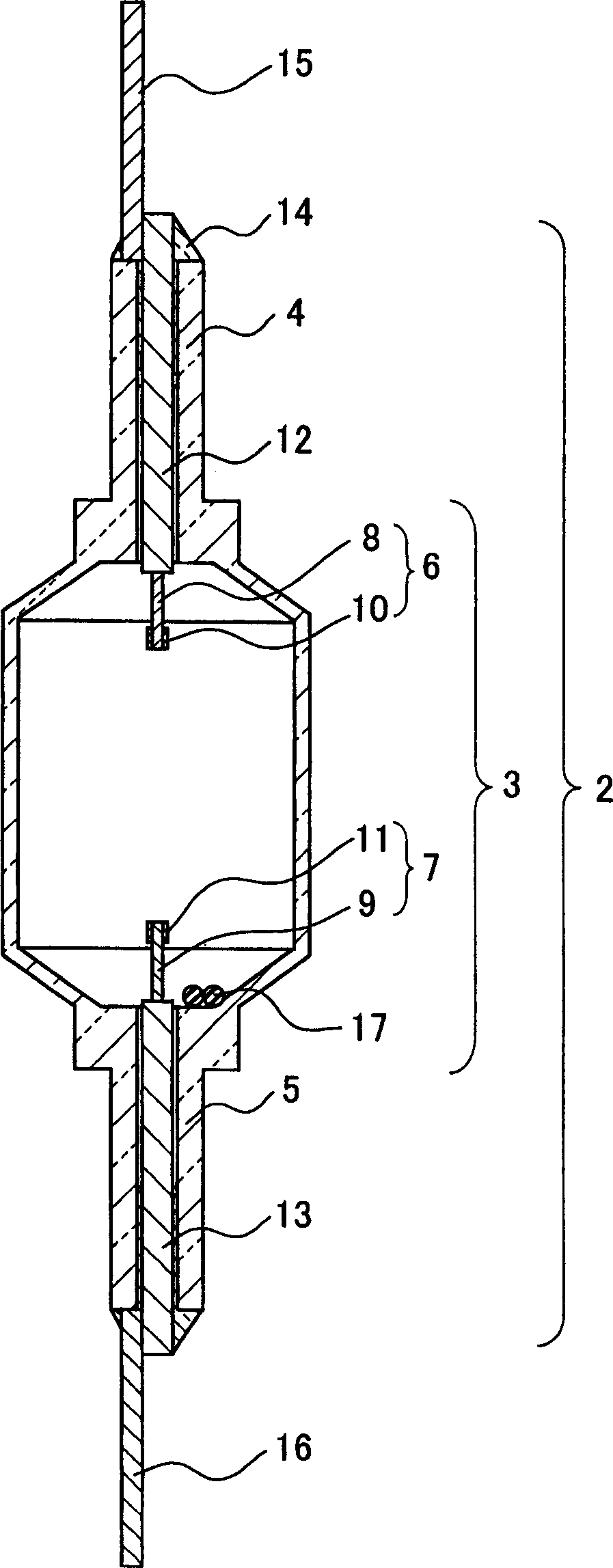

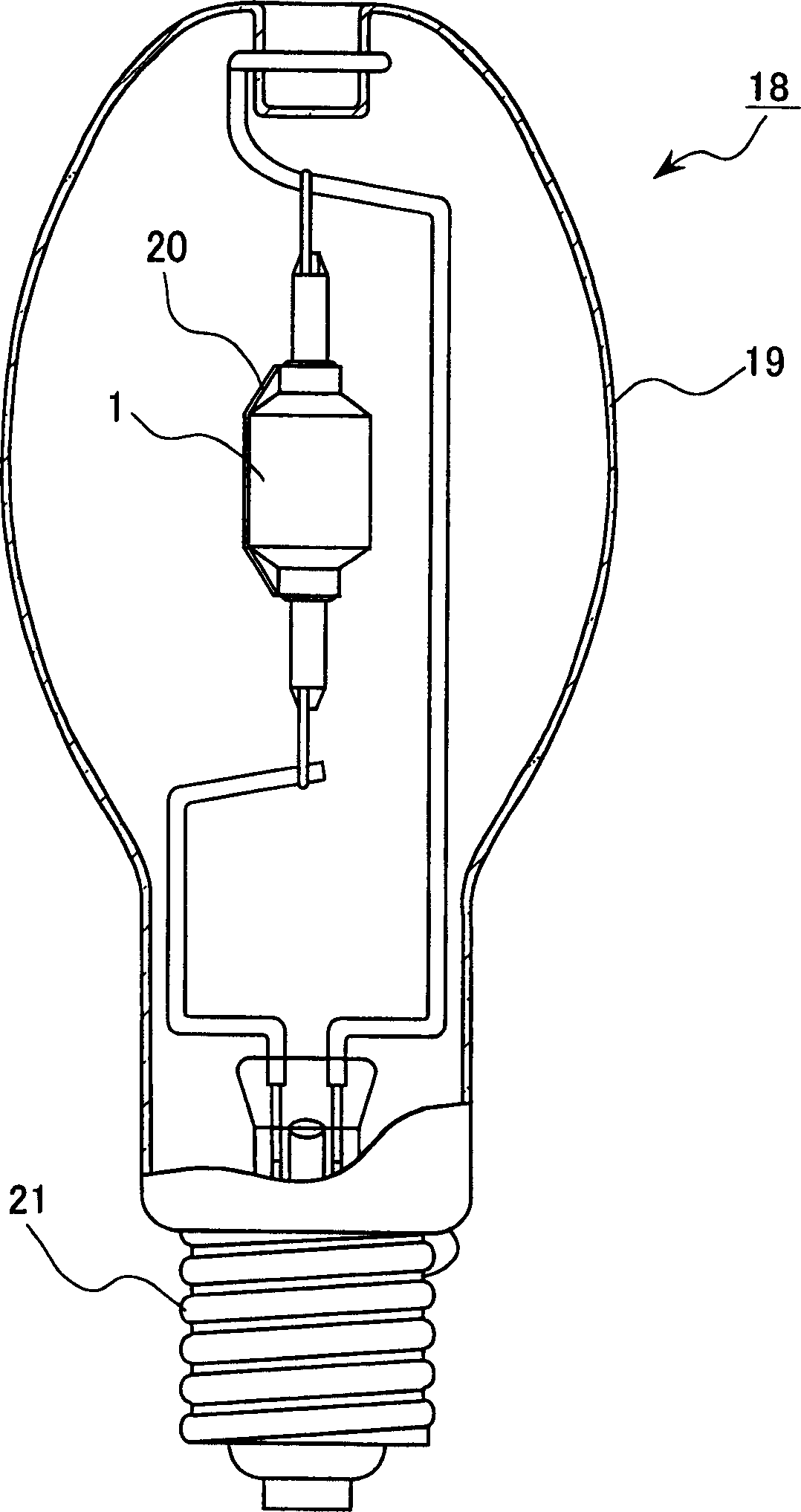

Embodiment 1

[0030] Preparation of CeI 3 : 2.4mg (40.0wt%), NaI: 3.15mg (52.5wt%), TlI: 0.27mg (4.5wt%), InI 0.18mg (3.0wt%) as the light-emitting substance 17, the lamp 18 was sealed, and its initial stage was measured. characteristics and beam maintenance in relation to aging.

[0031] As a result, it was observed that basically the encapsulation of TlI and InI broadened the discharge arc and also suppressed the bending of the discharge arc to the upper side of the arc tube and the side of the arc tube. Furthermore, the lamp 18 of this embodiment has an improved luminous flux maintenance rate related to aging, and can achieve a rated life time of 12,000 hours with a luminous flux maintenance rate of 60% or more. Basically, it can be said that the average excitation voltage Ve of thallium Tl and indium In is higher than the ionization voltage Vi (Ve>0.585Vi), so that such a discharge arc broadening effect is obtained.

[0032] Furthermore, it was confirmed that the encapsulation of thal...

Embodiment 2

[0034] As in Example 1, as the luminescent substance 17, CeI 3 : 2.5mg and NaI: 3.0mg, and sealed relative to the total amount of metal halides, TlI and InI whose composition was changed in the range of 0-15wt%, respectively, to prepare lamp 18, and measure its initial characteristics and aging correlation beam maintenance rate.

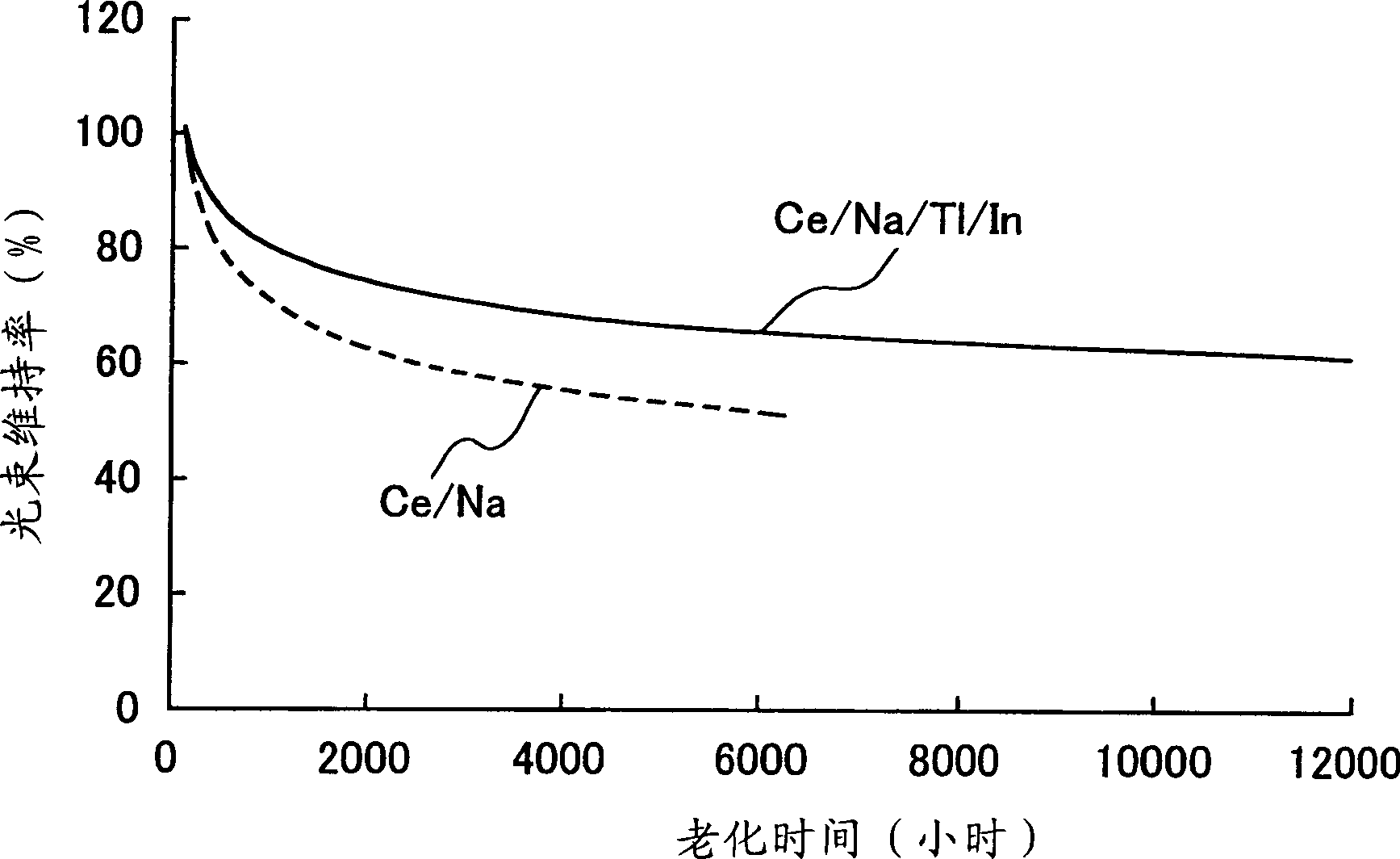

[0035]As a result, it was observed that the discharge arc was broadened basically accompanying the encapsulation of TlI and InI, and the bending of the discharge arc toward the tube wall was also suppressed. Moreover, the aging-related beam maintenance rate of the lamp 18 of the present embodiment is improved. If the encapsulation of TlI and InI is within the range of 1.0≤TlIwt%≤7.0, and in the range of 0.6≤TlIwt% / InIwt%≤4.0, it can be achieved The rated life time is 12,000 hours with the beam maintenance rate above 60%. The result is shown in image 3 In the Ce / Na / Tl / In graph. This can be said to be basically because the average excitation volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com