Medical composite material and its preparing method

A composite material and medical technology, which is applied in the field of medical composite materials and its preparation, can solve problems that have not been successfully developed, and achieve good barrier properties and mechanical properties, good transparency, and easy processing and molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

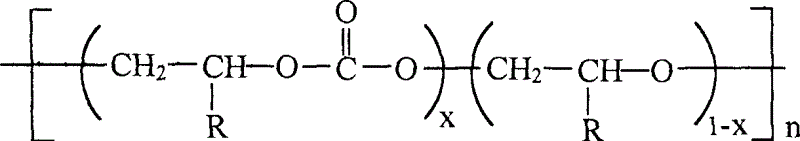

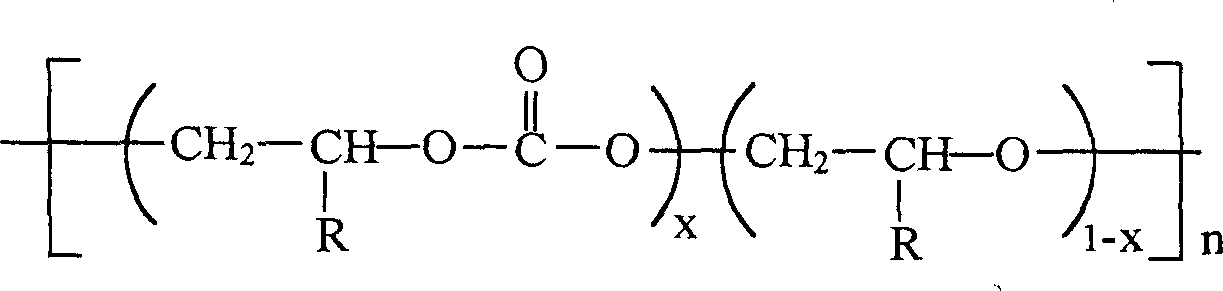

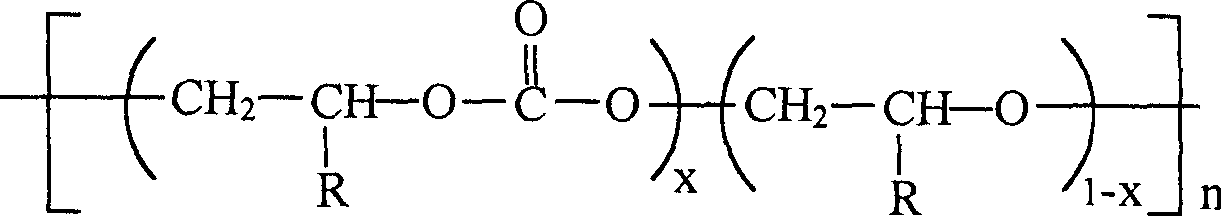

Image

Examples

preparation example Construction

[0023] The preparation method of the medical composite material provided by the present invention is as follows:

[0024] The above carbon dioxide copolymer is used as the intermediate barrier layer, polyethylene or polypropylene is used as the protective layer, and the three-layer co-extrusion technology is used at 140-190°C to prepare polyethylene / carbon dioxide copolymer / polyethylene or polypropylene / carbon dioxide copolymer Material / polypropylene medical composite material. The oxygen permeability of the composite material at 25℃ is lower than 6×10 -12 cm 3 -cm / cm 2 -s-cmHg, the permeability to water vapor is lower than 1.2×10 -7 cm 3 -cm / cm 2 -s-cmHg.

[0025] The above carbon dioxide copolymer is used as the intermediate barrier layer, polyethylene or polypropylene is used as the protective layer, and a five-layer co-extrusion method is used at 140-190°C to prepare polyethylene / carbon dioxide copolymer / polyethylene / carbon dioxide copolymer / Polyethylene or polypropylene / carb...

Embodiment 1

[0027] Example 1: A medical composite material, using carbon dioxide-ethylene oxide copolymer as the intermediate barrier layer, using polyethylene as the protective layer, and using three-layer co-extrusion technology at 140-190°C to prepare polyethylene / carbon dioxide -Ethylene oxide copolymer / polyethylene medical composite material, the oxygen permeability of the composite material at 25℃ is lower than 6×10 -12 cm 3 -cm / cm 2 -s-cmHg, the permeability to water vapor is lower than 1.2×10 -7 cm 3 -cm / cm 2 -s-cmHg. The material can be used for the production of disposable infusion bags.

Embodiment 2

[0028] Example 2: A medical composite material, using carbon dioxide-cyclohexane oxide copolymer as the intermediate barrier layer, using polypropylene as the protective layer, and using a five-layer co-extrusion method at 140-190°C to prepare polypropylene / Carbon dioxide-cyclohexane oxide copolymer / polypropylene / carbon dioxide-cyclohexane oxide copolymer / polypropylene medical composite material. At 25℃, the oxygen permeability of the composite material is lower than 1.5×10 -12 cm 3 -cm / cm 2 -s-cmHg, the permeability of water vapor is less than 0.2×10 -7 cm 3 -cm / cm 2 -s-cmHg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com