Pipeline powder coal on-line monitor

A monitoring device and a technology for pulverized coal, which are applied in measurement devices, block/powder supply/distribution, combustion methods, etc., can solve the problems of inability to real-time control the operation status of coal mills and pulverized coal separation devices, and long time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

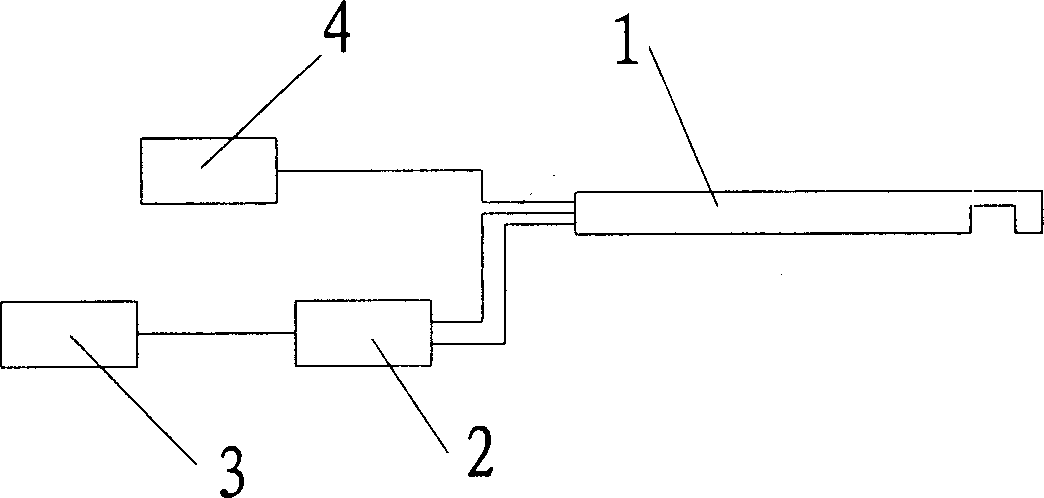

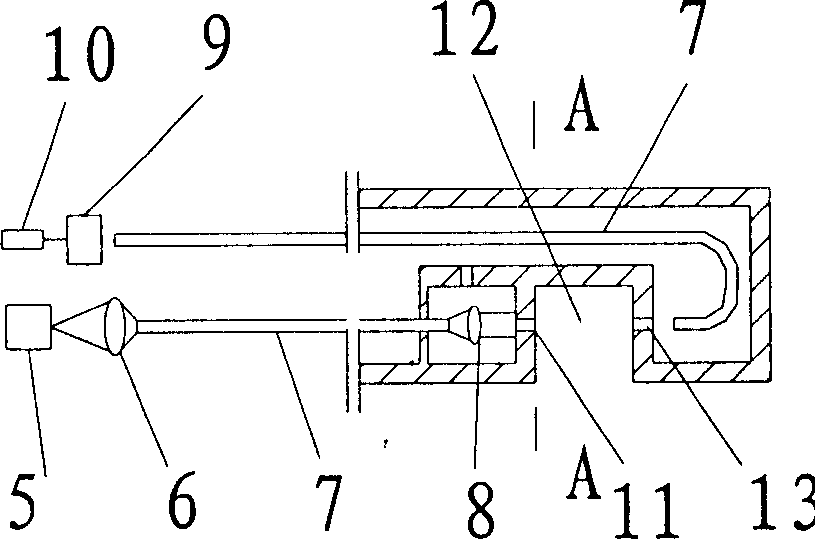

[0011] The pipeline pulverized coal online monitoring device of this embodiment is as follows: figure 1 As shown, it is mainly composed of probe 1, instrument box 2, computer 3, and air source 4. figure 2 The shown optical measurement components include a photoelectric transmitter and a photoelectric receiver. The photoelectric transmitter is composed of a light source 5, a coupling lens 6, an optical fiber 7, and a collimator lens 8. The photoelectric receiver includes a photosensitive detection element 9 and an amplifier 10. The light source 5, coupling lens 6, photosensitive detection element 9 and amplifier 10 are installed in figure 1 In the instrument box 2 shown, the light emitted by the light source 5 passes through the coupling lens 6, then is transmitted to the probe head through the optical fiber 7, and passes through the side of the measurement area 12 after being collimated by the collimating lens 8. Figure 4 The two small holes 11 shown are injected into the p...

Embodiment 2

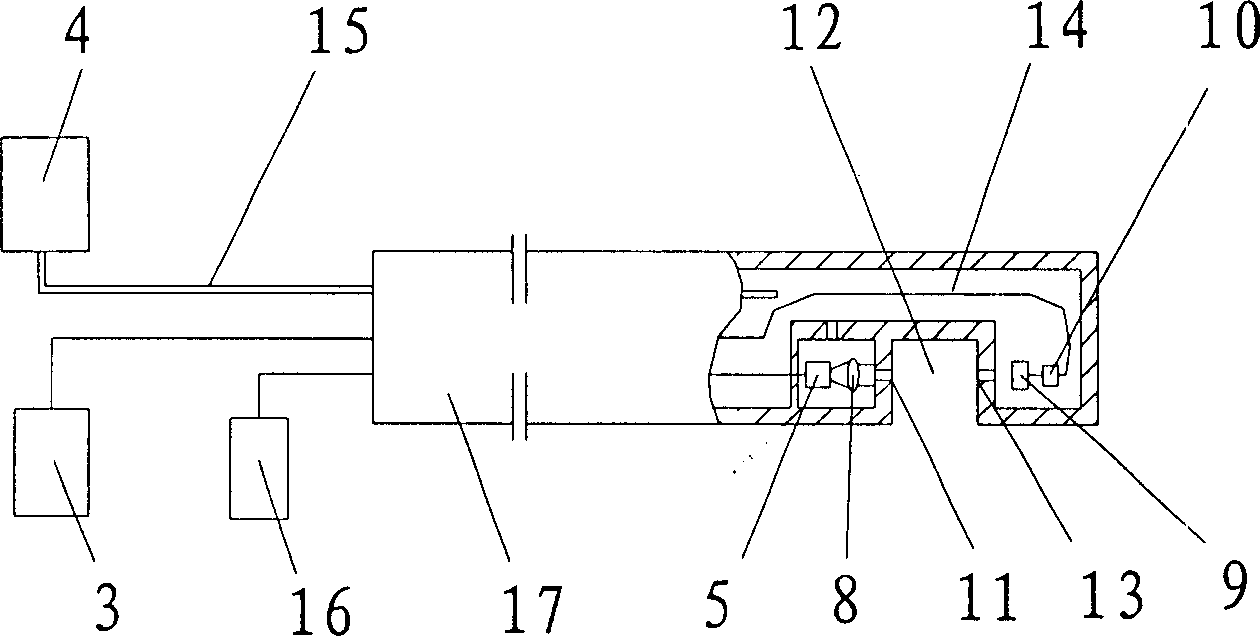

[0013] It installs optical measurement components at both ends of the measurement area of the probe head, such as image 3 As shown, the photoelectric transmitter is composed of a light source 5 and a collimator lens 8, and the photoelectric receiver includes a photosensitive detection element 9 and an amplifier 10. The light emitted by the light source 5 is collimated by the collimator lens 8 and the light beam passes through the measurement area 12 side like Figure 4 The two small holes 11 shown are injected into the pulverized coal flow in the measurement area 12, and the light beam passes through the small hole 13 on the other side of the measurement area 12 to the photosensitive detection element 9 and is received by the photosensitive detector 9, and then amplified by the amplifier 10 Send it to the computer 3 for processing and calculation through the transmission line 14, and the compressed air used to cool and protect the optical fiber or lens and prevent the small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com