Reversible circulation two phase biological nitrogen and phosphorus eliminating technology

A biological denitrification and double-cycle technology, applied in the field of nitrogen and phosphorus, can solve the problems of increased difficulty in operation control, poor operation stability, and low treatment efficiency, and achieve improved volume utilization, phosphorus removal rate, Reduce the effect of distractions and restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

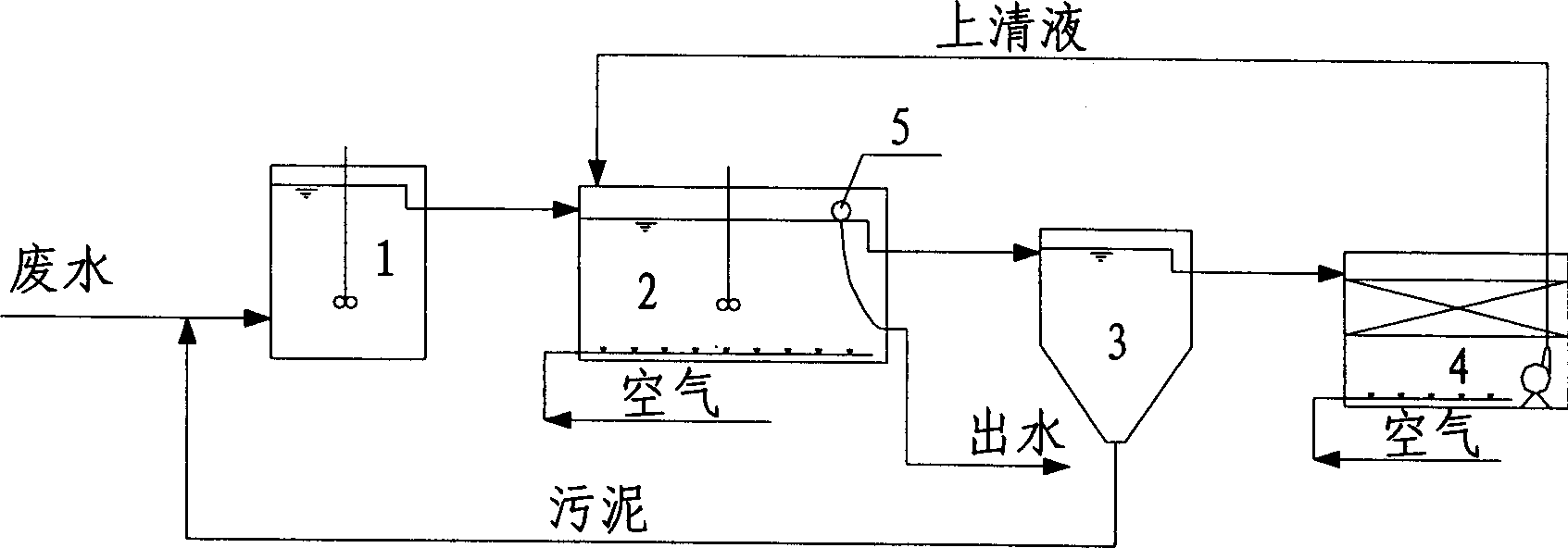

[0036] Embodiment one: see attached figure 1 As shown, an overall intermittent flow double-cycle two-phase biological denitrification and phosphorus removal process consists of a pre-anaerobic reactor 1, a suspension growth main reactor 2 operated in sequence batch mode, a sedimentation tank 3 and a biofilm reactor 4. Four main units are formed spatially, and the sedimentation tank 3 is arranged between the main reactor 2 and the biofilm reactor 4 .

[0037] exist figure 1 In the process, the waste water entering the system enters the pre-anaerobic reactor 1 together with the return sludge of the sedimentation tank 3, and stirs and reacts without oxygen supply, while entering and exiting; the mixed liquid flowing out of the anaerobic reactor 1 Entering the sequence batch main reactor 2, the four unit operations of water inlet / aeration, anoxic stirring, static sedimentation, water skimming / idle are completed sequentially, respectively to realize the degradation of organic matt...

Embodiment 2

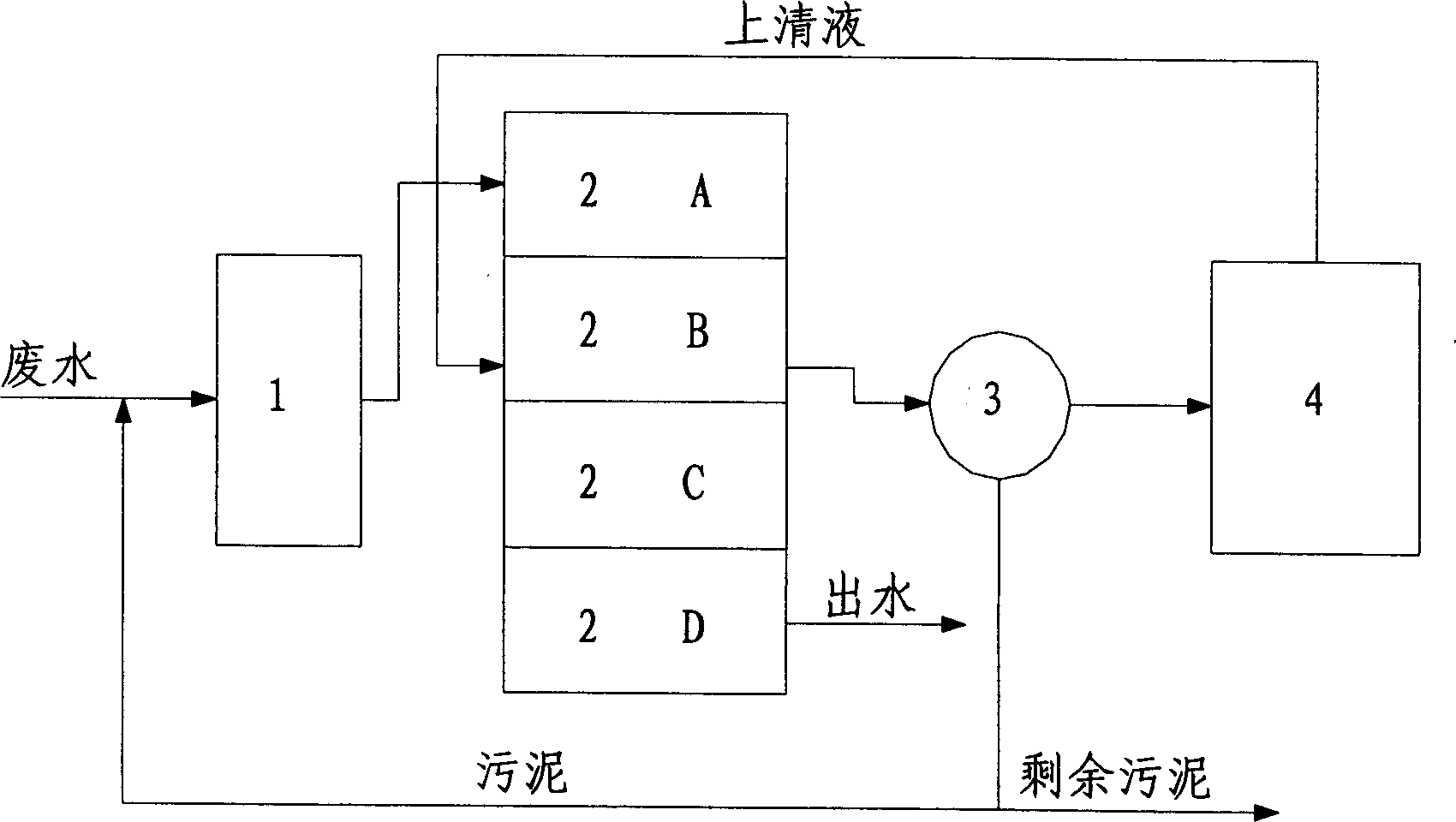

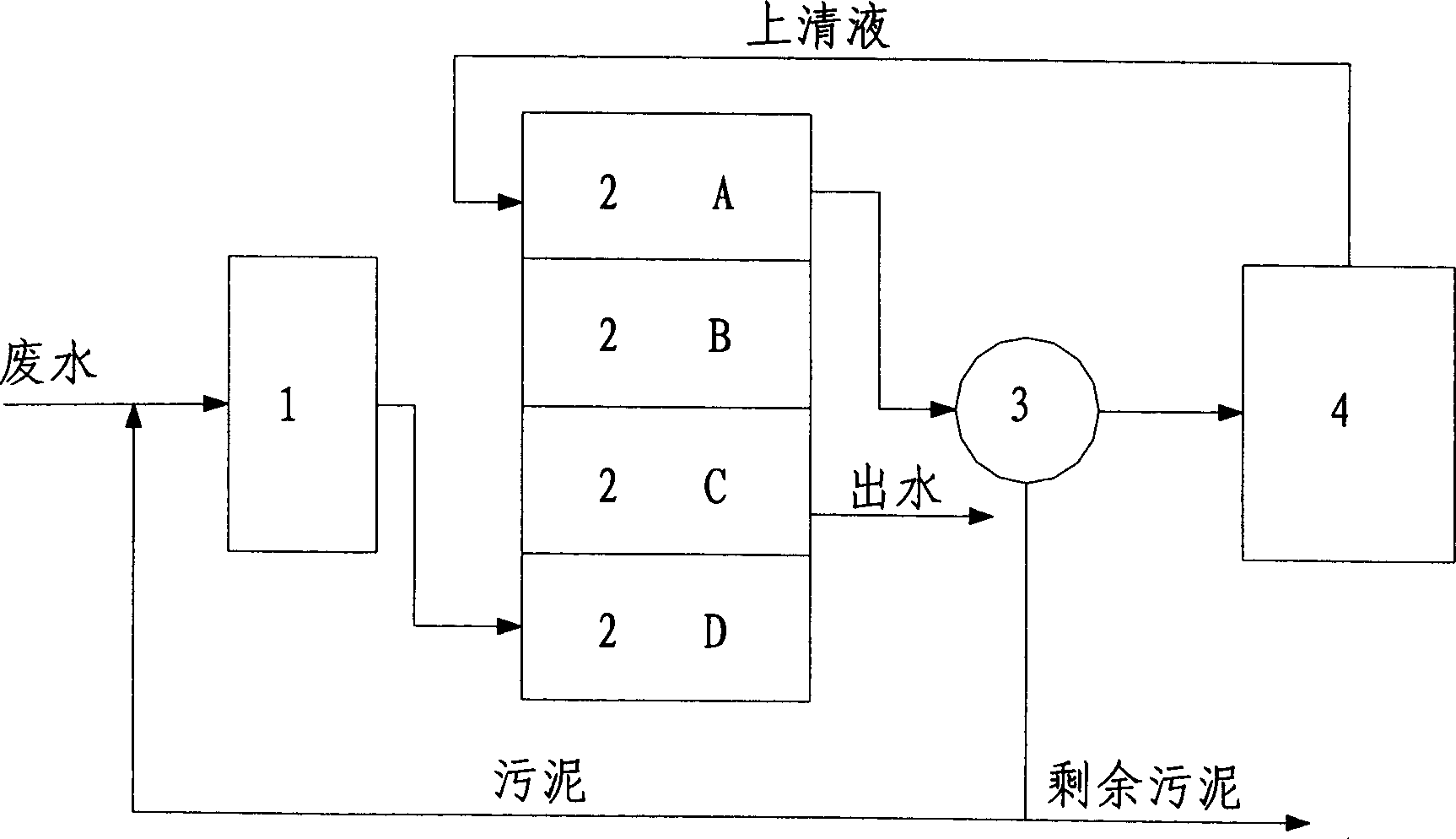

[0038] Embodiment two: see attached Figure 1 to Figure 5 As shown, an integral continuous flow partial intermittent double-cycle two-phase biological nitrogen and phosphorus removal process. The difference from Example 1 is that the main reactor is composed of 4 biological reaction pools A, B, C, and D that are independent of each other and operate in sequence batch mode. In this system, the anaerobic reactor 1 and the biofilm nitrification reactor 4 are always operated in a continuous flow mode, but according to the operation status of each reaction tank in the sequencing batch main reactor 2, the mixed liquid and nitrification liquid are sent to into the corresponding reaction pool. The sedimentation tank 3 also works in a continuous flow mode, sequentially receiving the mixed liquid from different reaction tanks, and sending the clarified effluent and return sludge to the biofilm nitrification reactor 4 and anaerobic reactor 1 respectively. . The four reaction tanks A, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com