Method of treating oil field waste water using flocculation electro multiphase catalysis and special flocculation equipment

A technology for oilfield wastewater and heterogeneous catalysis, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. The effect is not ideal enough to achieve the effect of low operating cost, easy operation and simple dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

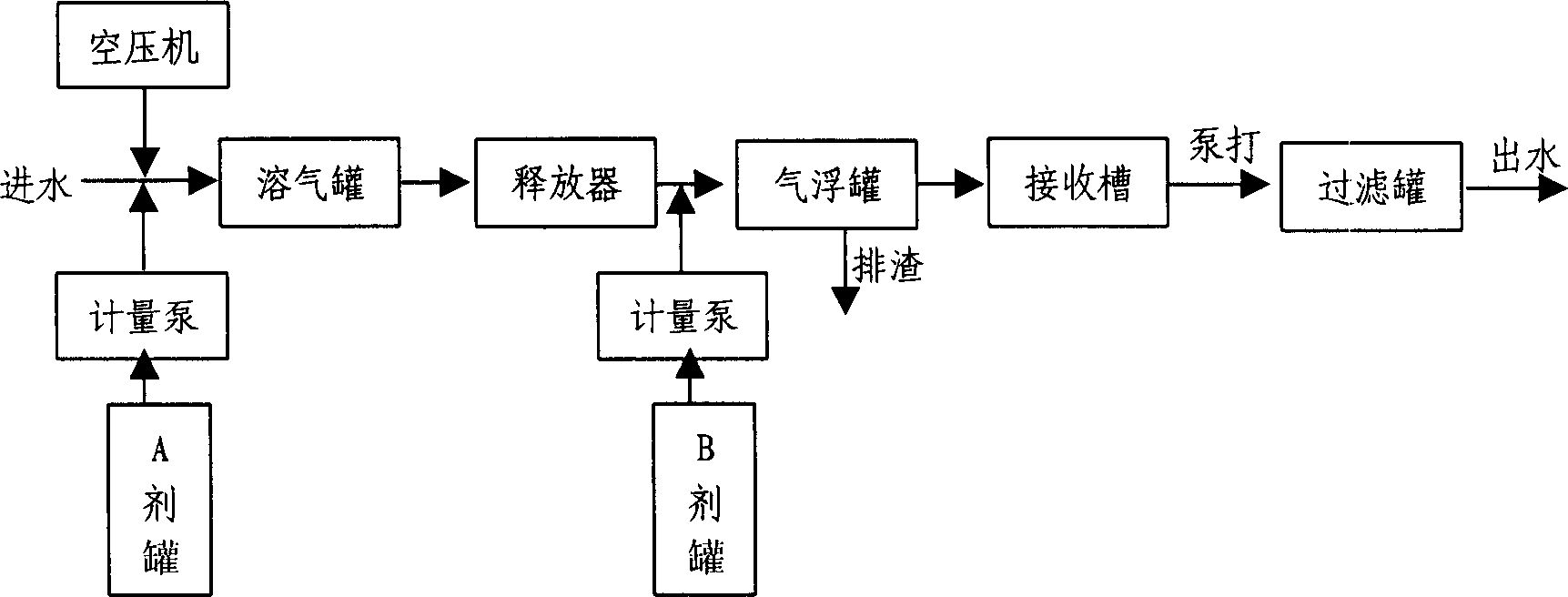

Method used

Image

Examples

Embodiment 1

[0026] Treatment Effect of Conventional Single Flocculant on Oilfield Wastewater

[0027] The flocculation effect takes the value of the optimal dosage of flocculant. The dosage of high molecular polymer coagulant is 50mg / L, COD Cr The analysis is carried out using the dichromate method (GB 11914-89) for the determination of chemical oxygen demand of water quality, the same as below.

[0028] Raw water COD Cr :561mg / L, PH: 7, the flocculation results are shown in Table 1.

[0029] Flocculant

Aluminum sulfate

(0.1%)

(0.125%)

(0.15%)

Poly aluminum

(0.05%)

Polyiron

(0.05%)

COD after flocculation Cr

(mg / L) *

180

188

221

286

272

COD after flocculation Cr

(mg / L) **

185

188

219

276

232

[0030] * The molecular weight of the coagulant used is above 14 million

[0031] ** The molecular...

Embodiment 2

[0034] Compared with eddy current processing efficiency

[0035] Under the same experimental conditions, the total pressure dissolved air flotation method and the eddy current method were used to treat the wastewater. Aluminum sulfate was used as the flocculant, and the amount was 0.1% of the wastewater volume. The treatment results are shown in Table 2.

[0036] Method

[0037] Judging from the experimental results, the full-pressure dissolved air flotation method is used to flocculate wastewater, and the treatment effect is better than that of the vortex method.

Embodiment 3

[0039] Flocculation at different pH values

[0040] From the treatment effect of Example 1, the flocculation effect of aluminum sulfate is the most obvious. When detecting the influence of different pH values on the flocculation, aluminum sulfate is used as the flocculant, and the amount is 0.1% of the wastewater volume.

[0041] Raw water COD Cr :561mg / L, PH: 7, treatment results are shown in Table 3.

[0042] PH value

[0043] From the results, when the pH value of wastewater is neutral, the flocculation treatment effect is better. In actual operation, the pH value should be adjusted to 7-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com