Plastic optical fiber with fluorizated packet-layer and its prepn. method

A technology of a plastic optical fiber and a manufacturing method, which is applied in the field of fluorinated clad plastic optical fiber and its manufacturing, can solve the problems of high price, increased optical fiber loss, and high equipment requirements, so as to prevent light leakage, save equipment investment, and control fluorine degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

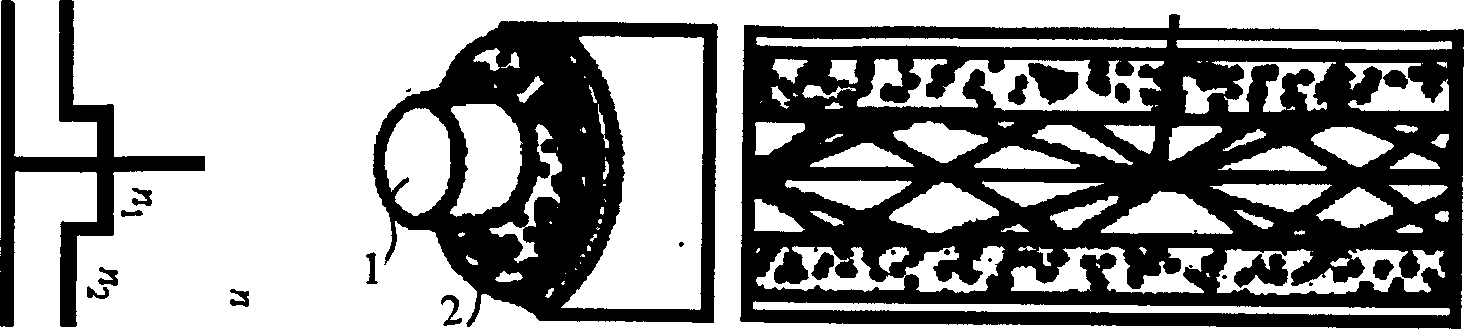

[0033] figure 1 A structural schematic diagram of the multimode step plastic optical fiber (SIPOF) of the present invention is given. see figure 1 , there is a fluoride cladding 2 on the outer periphery of the core 1.

Embodiment 2

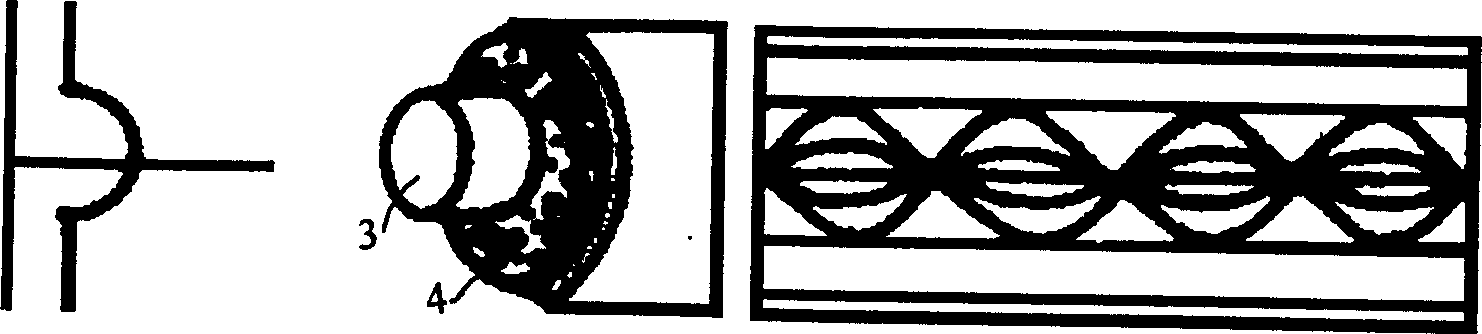

[0035] figure 2 A schematic structural view of the multimode gradient plastic optical fiber (GIPOF) of the present invention is given. see figure 2 , there is a fluoride cladding 4 on the periphery of the core 3 .

Embodiment 3

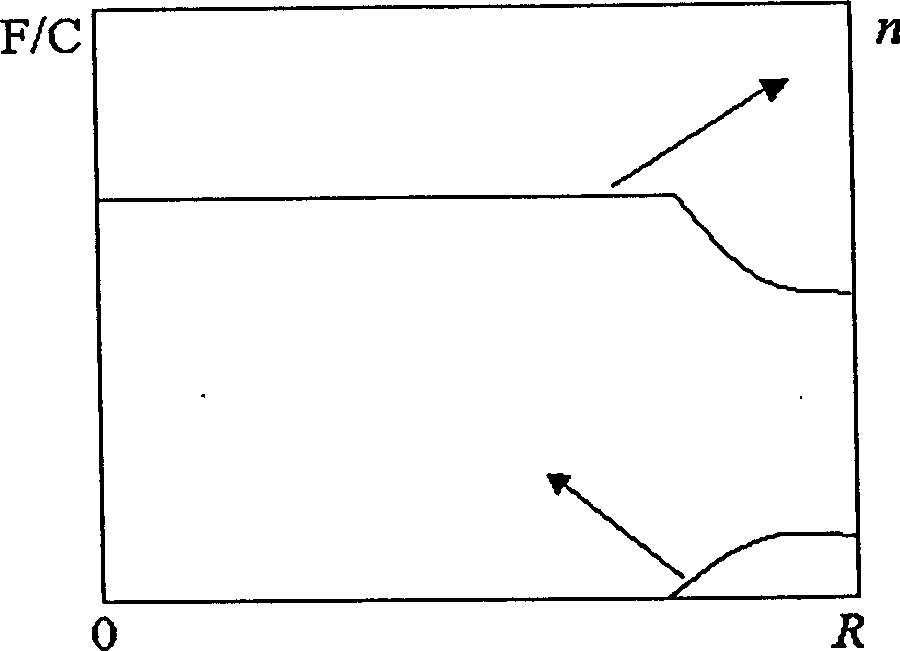

[0037] Purify methyl methacrylate by distillation under reduced pressure, then add the purified initiator and chain transfer agent, under the protection of high-purity nitrogen with a purity greater than 99.9%, polymerize at 40-80°C for 5-48h, and then extrude extruding, pulling, and cooling to obtain a polymerized high-purity polymethylmethacrylate (PMMA) core material, and melt extruding fibers with a diameter of 1 mm through the extruder. This fiber is put into the fluorination furnace that contains 10% volume ratio (1 standard atmospheric pressure) fluorination agent, carries out fluorination reaction certain hour (0 # Sample fluorination 0h, 2 # The sample was fluorinated for 2h, 4 # The sample was fluorinated for 3h, 5 # Sample fluorination 4h). The relationship between the surface F / C atomic ratio and the fluorination time is analyzed by electron spectroscopy. Figure 4 . It can be seen that the degree of fluorination increases with the prolongation of fluorination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com