Film Pollution treating ultrasonic wave and magnetic field equipment

A technology of ultrasonic and membrane fouling, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., to achieve the effect of preventing membrane fouling, saving costs, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

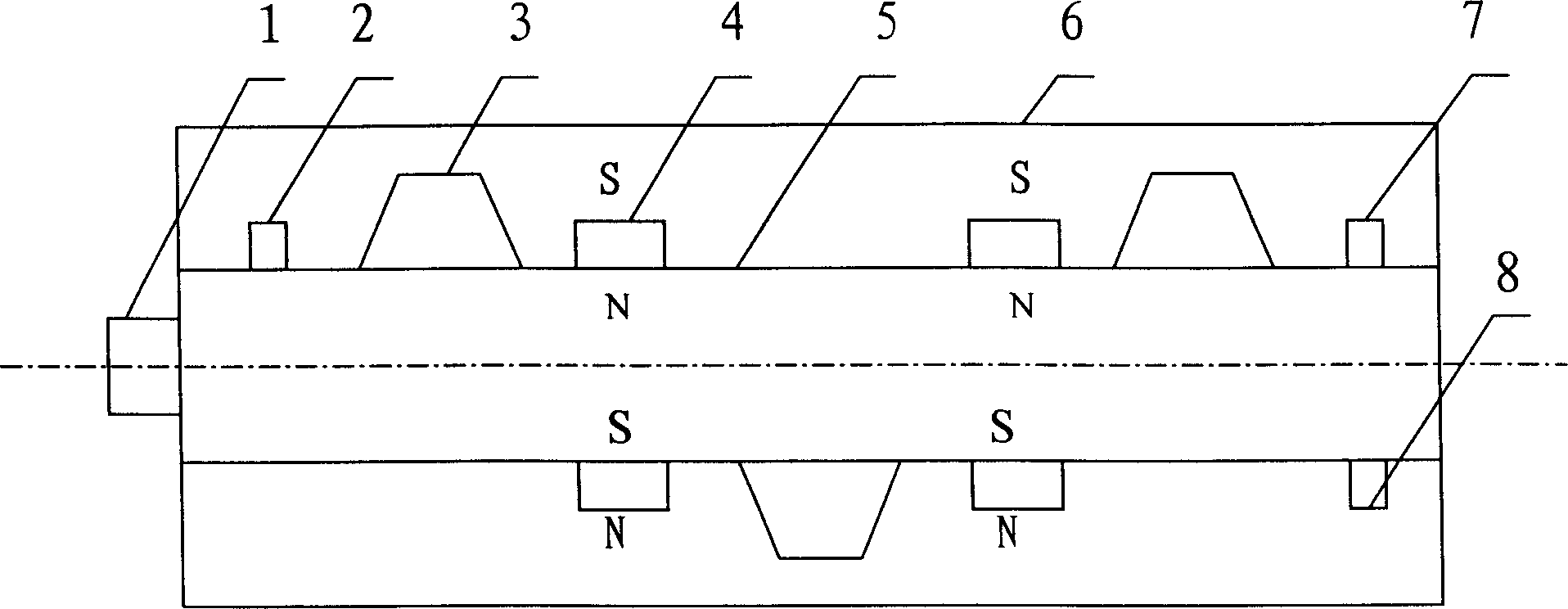

[0016] Such as figure 1 As shown, the membrane module 5 is a hollow structure of a garden barrel, with both ends closed, and its inner layer is an ultrafiltration membrane made of fiber material, and the outer wall is a cover body made of stainless steel. Water inlet 7, water outlet 1, backwash outlet 2 and concentrate outlet 8, and a water outlet 1 is provided on one end face. The ultrafiltration membrane can be backwashed through the backwash port 2, and the dirt is discharged from the concentrate outlet 8. Two pairs of tile-shaped permanent magnets 4 are fixed on the outer wall of the membrane module 5, and three ultrasonic transducers 3 are installed at intervals with the permanent magnets 4. The magnetic field strength of the permanent magnets 4 is 0.2T, and each ultrasonic transducer The power of the transducer is 10W, and all the transducers are connected in parallel to an ultrasonic power generator with an output frequency of 45KHz. A tubular plastic protective cover...

Embodiment 2

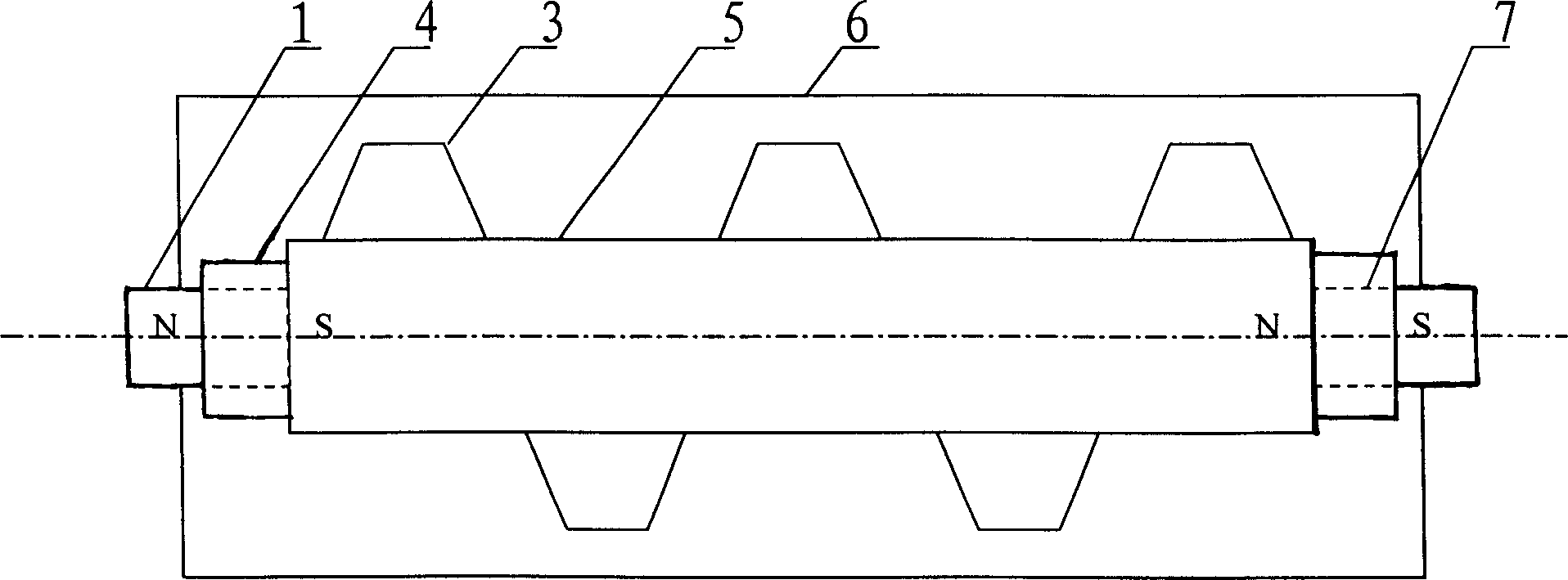

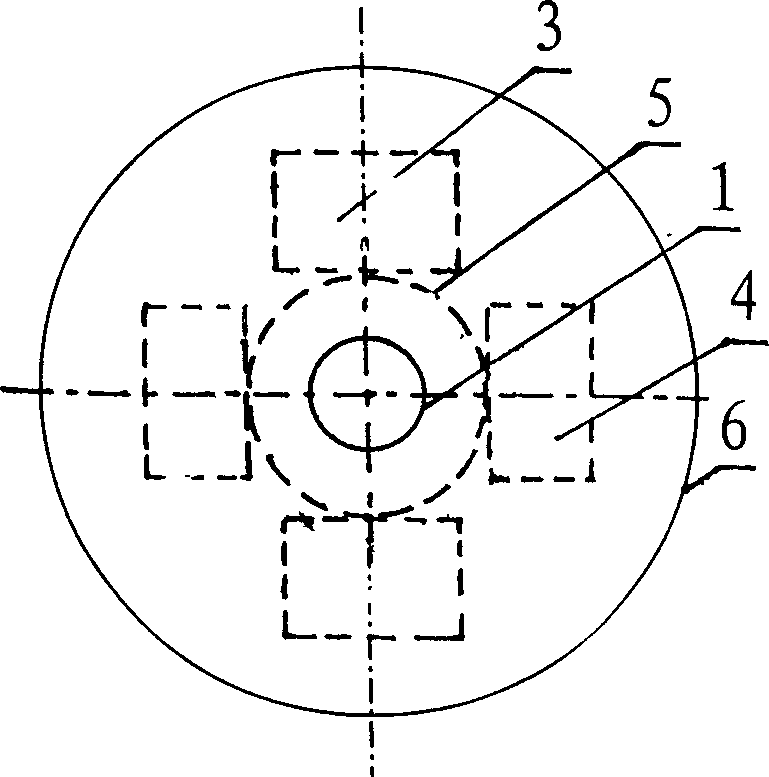

[0018] Such as figure 2 , image 3 As shown, the membrane module 5 is a hollow barrel structure, the inner layer is a roll-type reverse osmosis membrane made of aromatic polyamide composite material, the outer wall is a cover body, and the maximum operating pressure of the membrane is 8.27Mpa. A water inlet 1 and a water outlet 7 are respectively provided at both ends of the membrane module 5 , and permanent magnets 4 are respectively installed on the outer sides of the water inlet and the water outlet, and the magnetic field strength thereof is 0.25T. Five ultrasonic transducers 3 are installed alternately on the outer wall of the membrane assembly 5, each ultrasonic transducer has a power of 30W, and all transducers are connected in parallel to an ultrasonic power generator with an output frequency of 45KHz. A tubular plastic protective cover 6 is set outside the ultrasonic transducer 3 . After using the invention, in the seawater desalination process, its cleaning freque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com