Lithium-containing hydrogen-storing alloy electrode material and its prepn

A hydrogen storage alloy and electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of increasing processes and equipment, making it difficult to realize industrialization, and increasing product costs, so as to achieve less energy consumption and easy industrialization And promotion, the effect of long cycle life

Inactive Publication Date: 2003-05-14

NANKAI UNIV

View PDF3 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

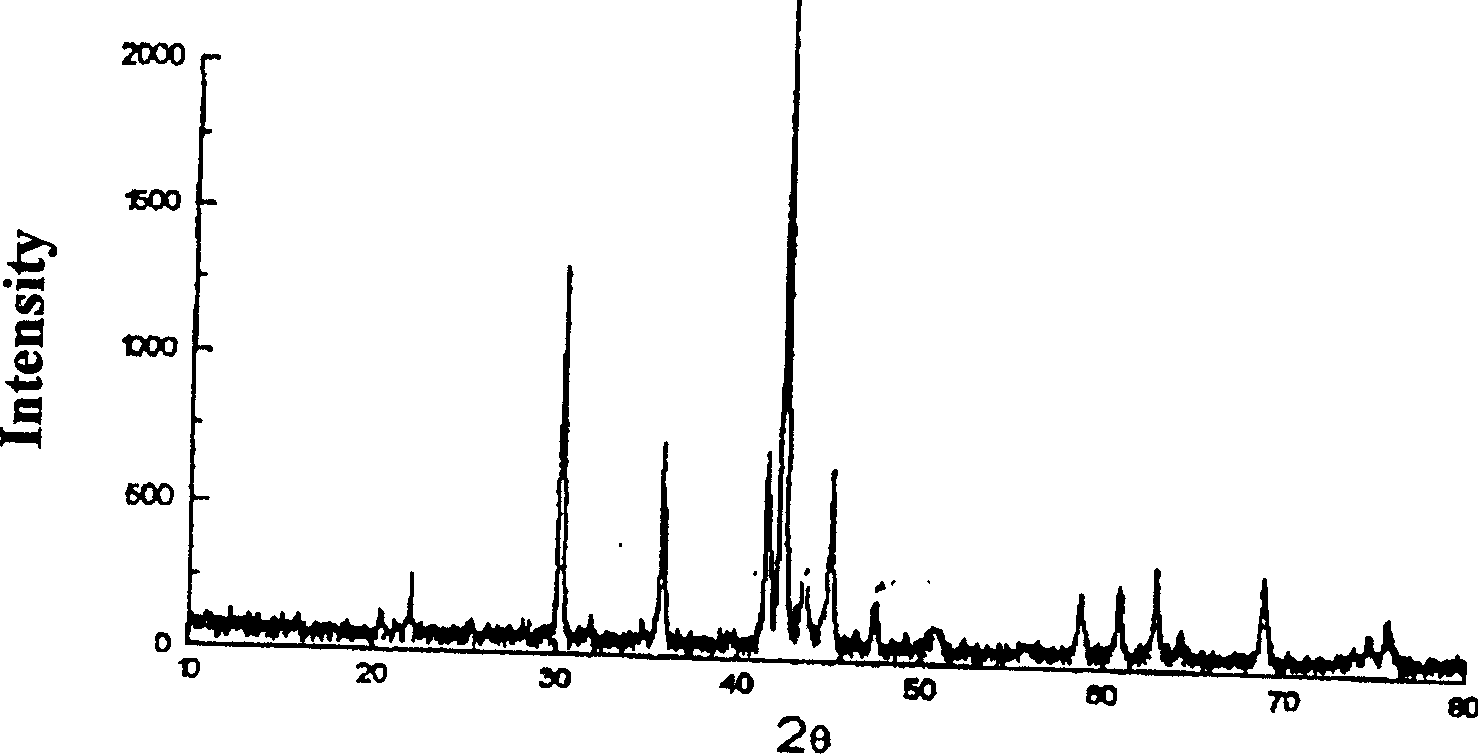

Embodiment 2

[0020] the element

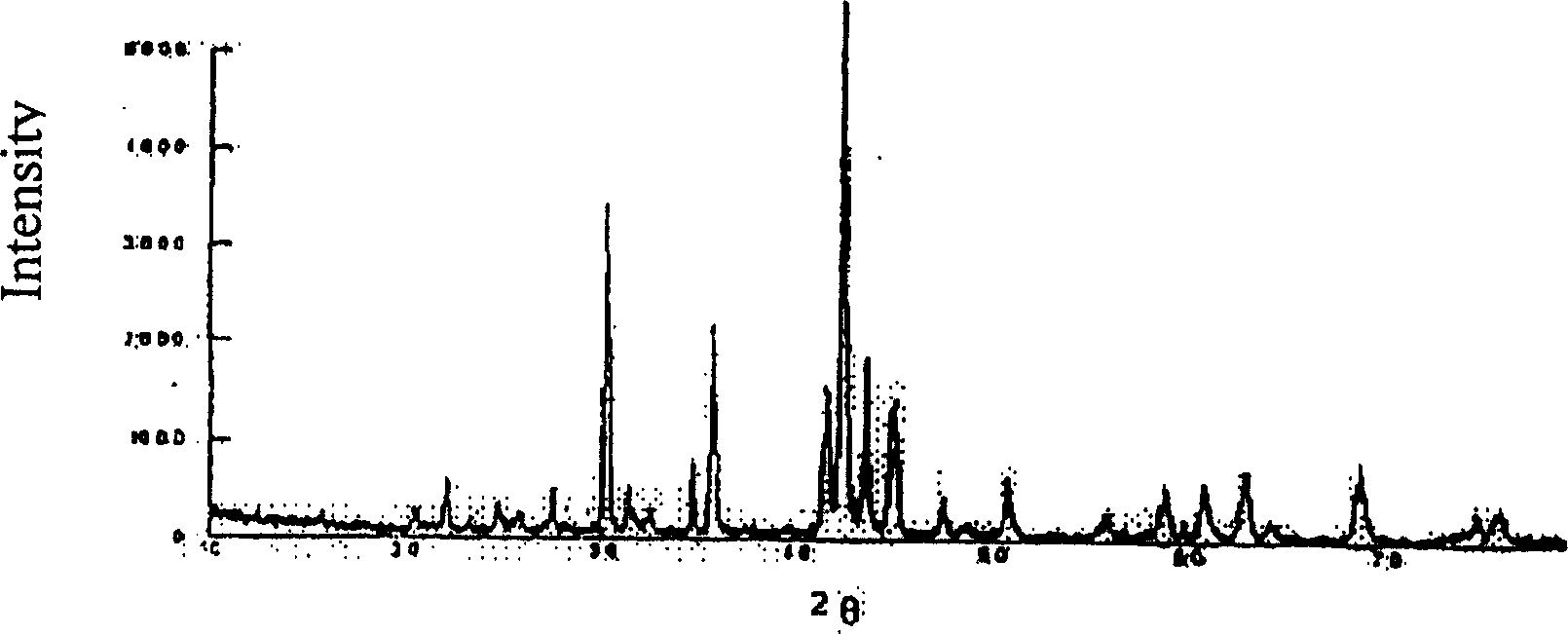

Embodiment 3

[0022] cycle

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

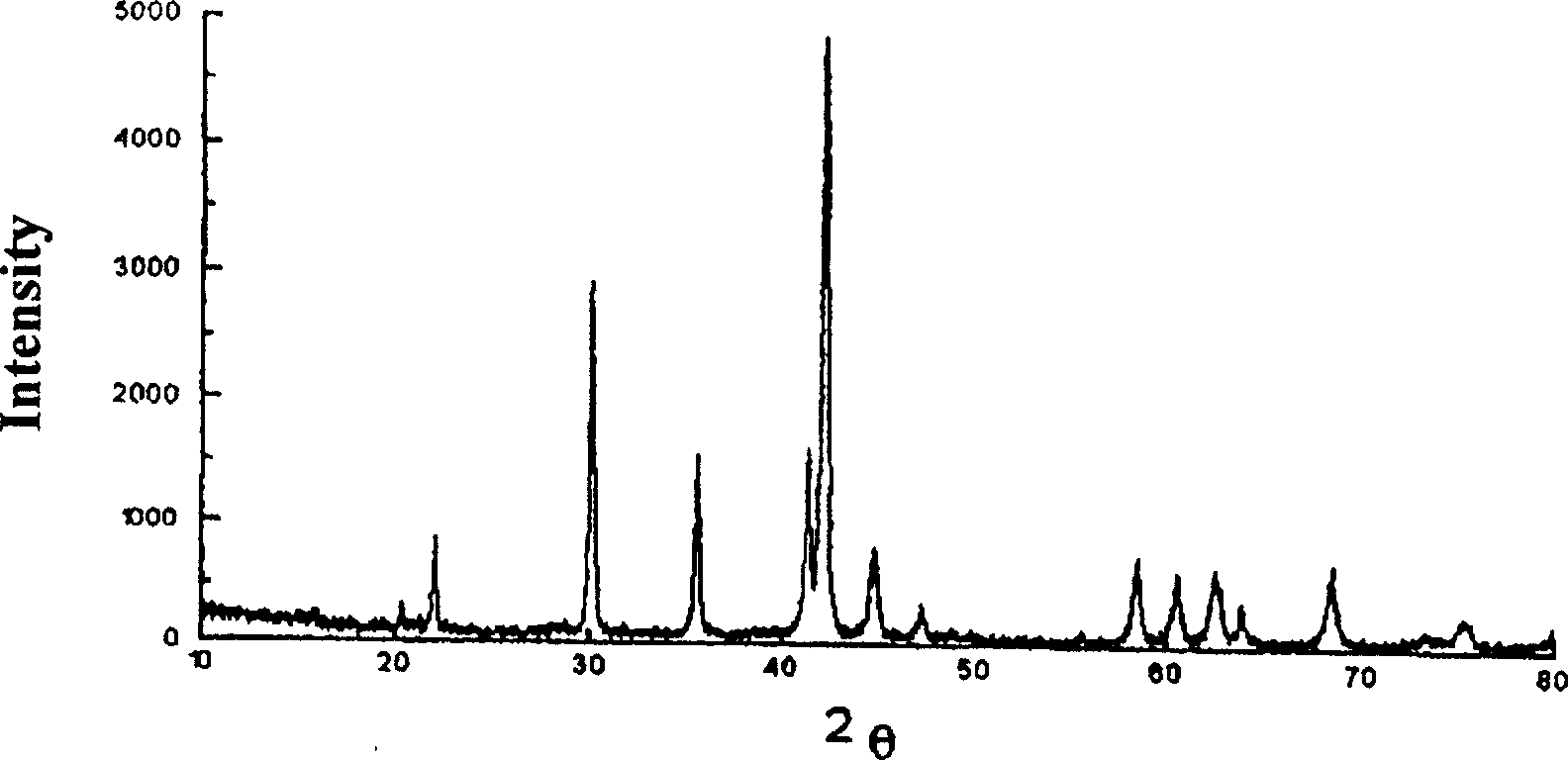

In the present invention, during the ball milling of AB5 type hydrogen-storing alloy is a special high-energy ball mill, LiH or Li is made to form alloy mechanically with AB5 type hydrogen-storing alloy to prepare composite hydrogne-storing alloy electrode material with Li content of 0.1-2.0 wt%. The present invention is also suitable for preparing composite lithium-containing hydrogen-storing alloy electrode material with AB, A2B and AB2 type hydrogen-storing alloy. The present invention utilizes the leaching of Li in alkali solution of make hydrogen-storing alloy form pores and to raise theelectric catalytic activity of Ni / MH cell negative pole. In addition, Li dissolved in the alkali solutio to form LiOH can protect the positive pole of the cell, and raise the circulation life and discharge capacity of cell.

Description

technical field [0001] The invention relates to a lithium-containing composite hydrogen storage alloy electrode material and a preparation method thereof, belonging to the hydrogen storage alloy electrode material and preparation technology. Background technique [0002] Nickel-metal hydride batteries (Ni / MH batteries) have been rapidly developed due to their advantages of high energy density, long cycle life, no memory effect and no environmental pollution. Small cylindrical Ni-MH batteries have been industrialized and commercialized; large-capacity power Ni / MH batteries have been selected as power batteries for electric vehicles due to environmental pollution caused by fuel motorcycles and automobile emissions, and research and development are being stepped up. At present, the negative electrode hydrogen storage material of Ni / MH battery is basically multi-component AB 5 Hydrogen storage alloys, where Mm(Ni-Co-Mn-Al) 5 (J6 2020-25-A, CA107:99728f) is widely used. Hydrog...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M4/38H01M4/40

CPCY02E60/12Y02E60/10

Inventor 吴锋高学平曲金秋金季荪李玉刚牛广良袁华堂宋德瑛

Owner NANKAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com