Method for treating acidic waste-water contg. nonferrous metals

A technology for acidic wastewater and non-ferrous metals, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. To achieve the effect of reducing the amount of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

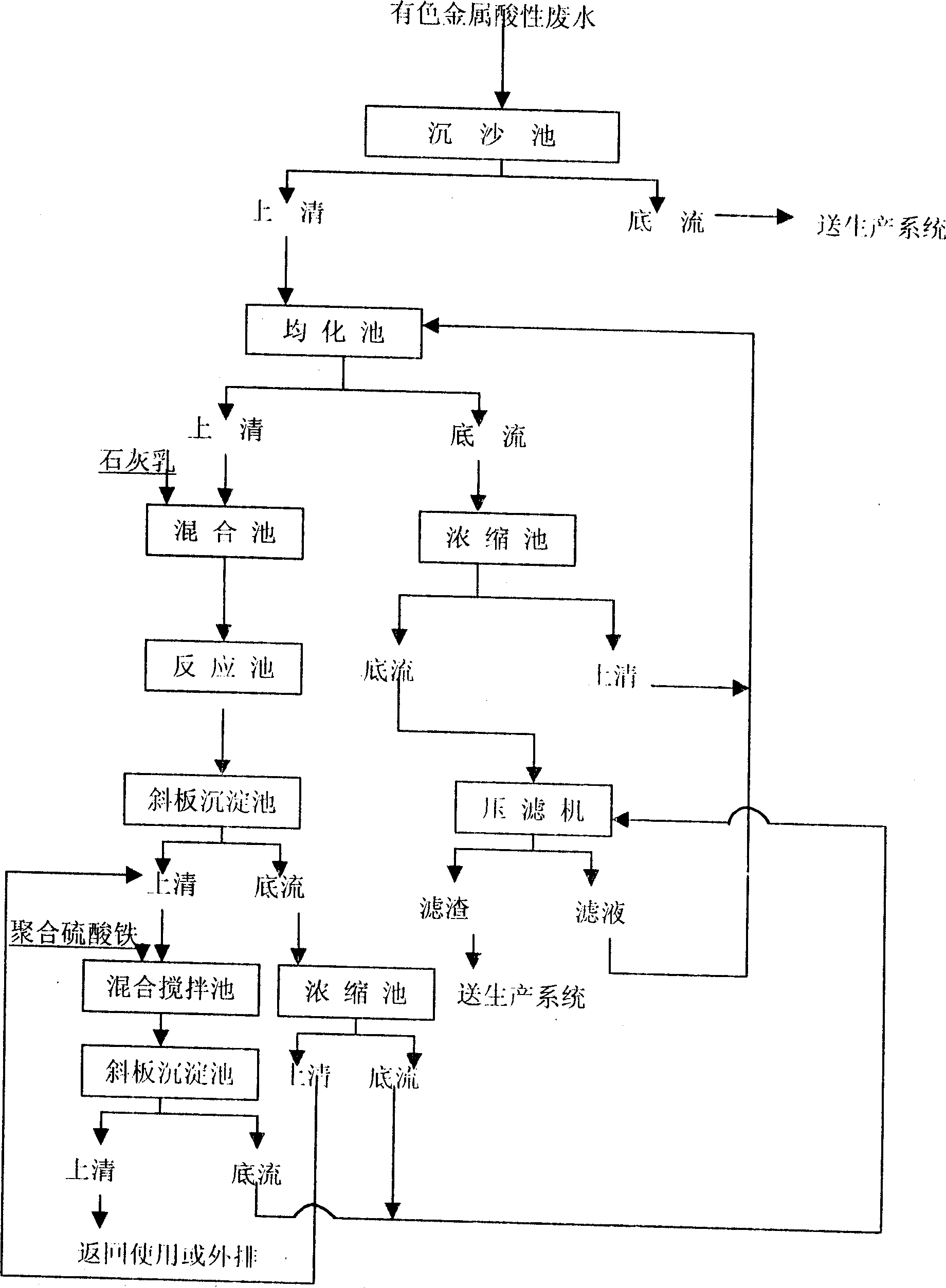

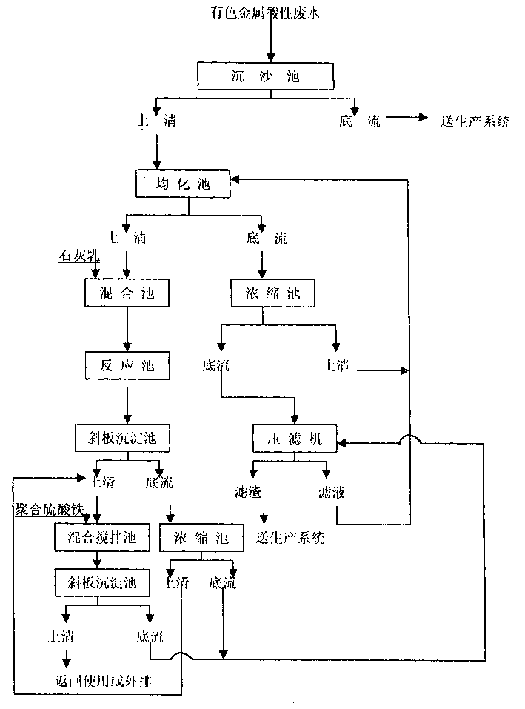

[0016] Referring to the accompanying drawings, the accompanying drawings are a process flow chart of the present invention's two-stage method for treating nonferrous metal acidic wastewater. The acidic wastewater containing ferrous metal ions enters the mixing tank after sedimentation and homogenization, and milk of lime is added to the mixing tank. , to carry out a period of lime neutralization, after neutralization, the liquid is sent to the reaction tank and the inclined plate sedimentation tank, and the supernatant of the sedimentation tank is put into the mixing and stirring tank, and polyferric sulfate is added to the stirring tank to carry out the second stage of polyferric precipitation, and the mixed liquid enters another The inclined plate sedimentation tank, the supernatant is returned to use or discharged, the bottom flow of the homogenization tank and the bottom flow of other processes enter the filter press for filtration, the filter residue is sent to the producti...

example 2

[0021] Wastewater composition (mg / l): Cu1.82, Pb9.40, Cd7.12, Zn138.48, pH value 3.5.

[0022] The milk of lime concentration is 6%, until the pH value reaches 7.5, the composition of the supernatant (mg / l) after neutralization is sampled and tested: Cu0.40, Pb1.04, Cd0.16, Zn2.14, and the pH value is 7.5.

[0023] Concentration of 5% polyferric sulfate 70PPM (equivalent to 28kg / hour), sampling test supernatant composition after polymerization precipitation (mg / l): Cu0.28, pb0.97, Cd0.07, Zn1.93, pH value 7.5 , and the rest are the same as Example 1.

example 3

[0025] Wastewater composition (mg / l): Cu5.65, Pb11.79, Cd6.89, Zn629.65, PH value 4.0.

[0026] The concentration of milk of lime is 10%, and until the pH value reaches 9.0, the composition of the supernatant (mg / l) after neutralization is sampled and tested: Cu0.28, Pb1.31, Cd0.16, Zn9.55, and the pH value is 9.0.

[0027] The polyferric sulfate 200PPM of concentration 20%, the supernatant liquid composition (mg / l) after the sampling assay polymerization precipitation: Cu0.24, Pb0.92, Cd0.07, Zn2.00, pH value 9.0, all the other are with example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com