Adjustable optical fibre polarizer and production thereof

A technology for polarizers and manufacturing methods, applied in the field of tunable polarizers and optical fiber tunable polarizers, to achieve the effects of miniaturization of tuning devices, small insertion loss, and large tuning range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

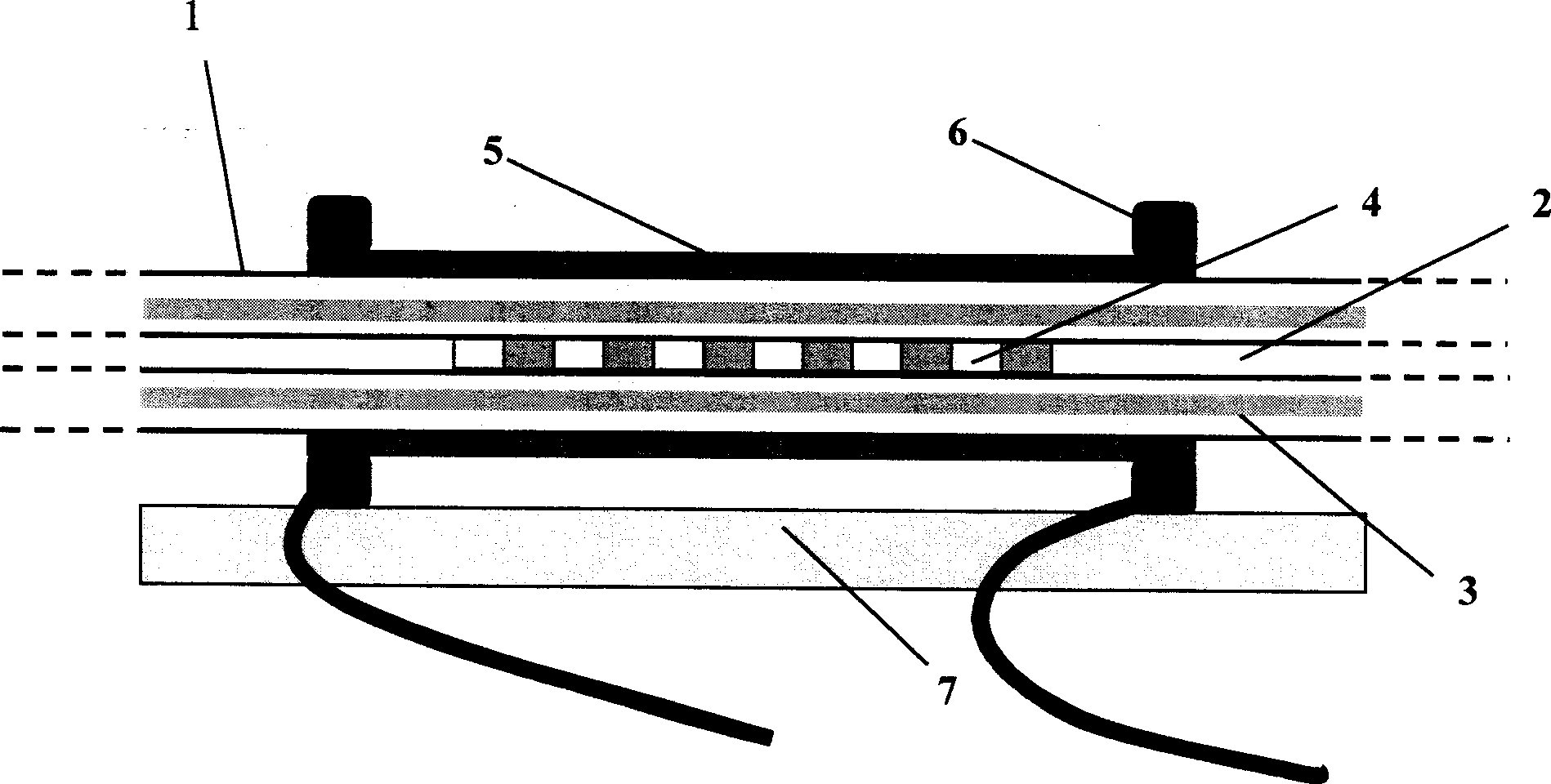

[0028] We choose a Panda polarization-maintaining fiber as the high birefringence fiber 1, and write a long-period fiber grating 4 with a period of 450 μm and a length of 8 cm on the core 2 by means of ultraviolet irradiation. Then we use the method of ion sputtering to coat Ti, or Pt, or Au and other metals on the outside of the cladding 3 of the fiber grating 4 uniformly as the inner surface layer, and then use the chemical deposition plus electroplating method to coat metal Ni on the inner surface layer. As the outer layer, a metal resistance collar 5 is formed. This not only improves the strength between the optical fiber and the metal layer, but also is very convenient when soldering. The metal resistance film 5 has a thickness of about 2 μm and a resistance of 3Ω. A pair of lead electrodes 6 are welded on both ends of the metal resistance film 5, and they are fixed on an insulating base plate 7 to keep the long-period fiber grating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com