Air permeable upper downspout of pouring basket in continuous casting

A continuous casting tundish and nozzle brick technology, which is applied to casting equipment, casting molten material containers, manufacturing tools, etc., can solve the problems that the ventilating upper nozzle cannot be adapted, the number of continuous casting can only reach 8 times, and microcracks are easy to occur. , to achieve the effect of high precision in appearance size, prevent adhesion, and prevent shrinkage of pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

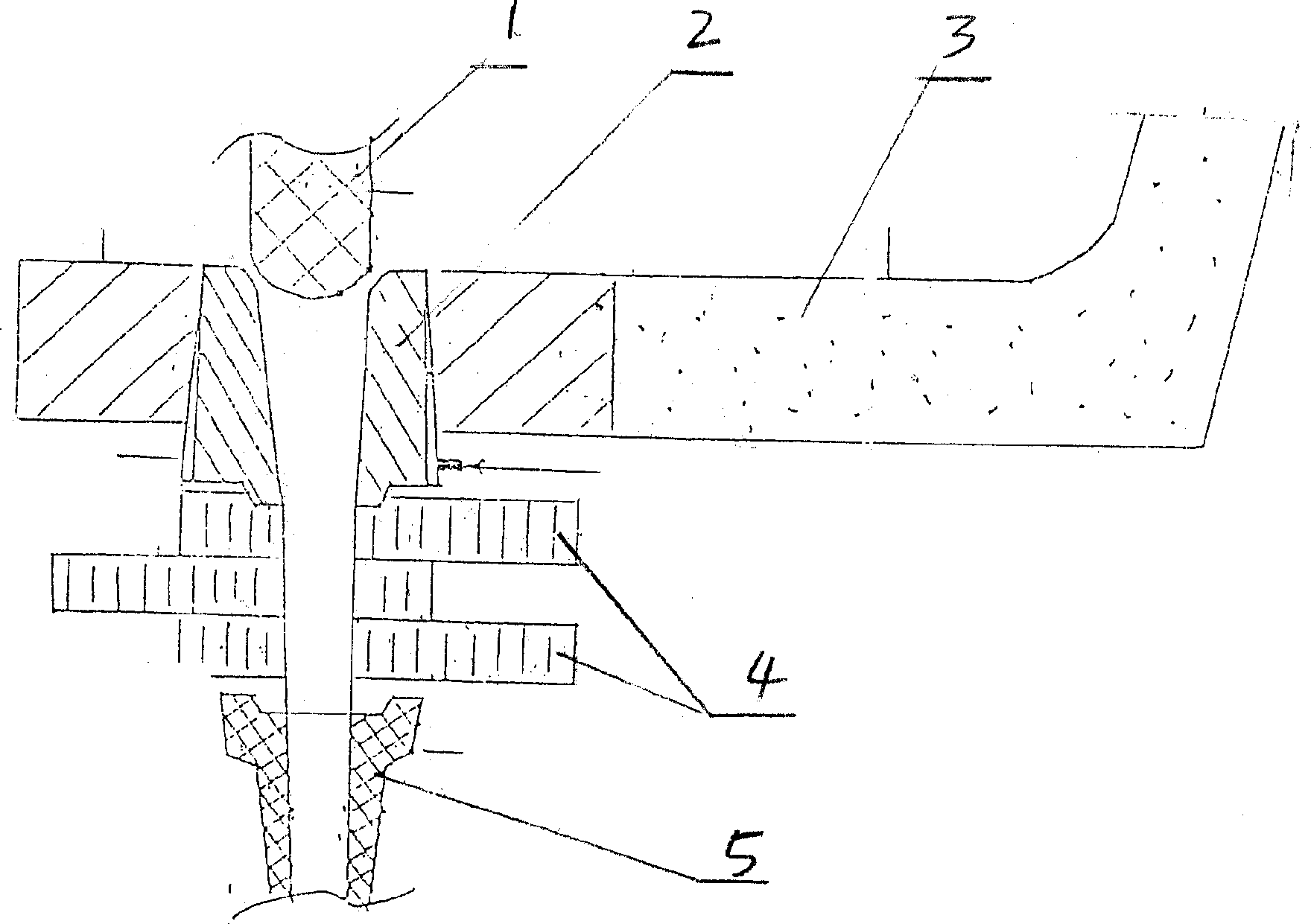

[0027] Such as figure 1 As shown, the vent 2 of the continuous casting tundish is located at the bottom of the tundish 3, and the lower part is connected with the three-layer slide plate 4 and the submerged nozzle 5. Ventilation upper nozzle 2 tops are stopper rod 1.

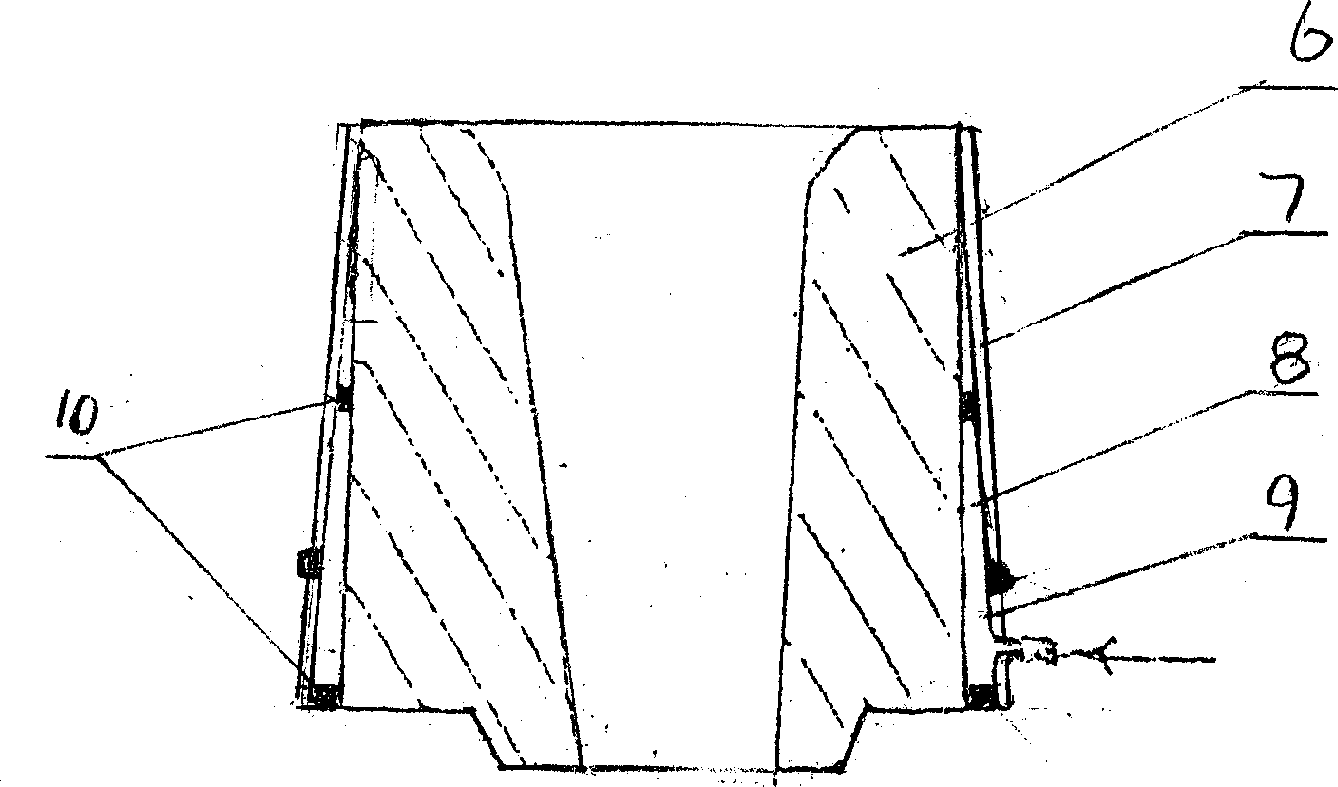

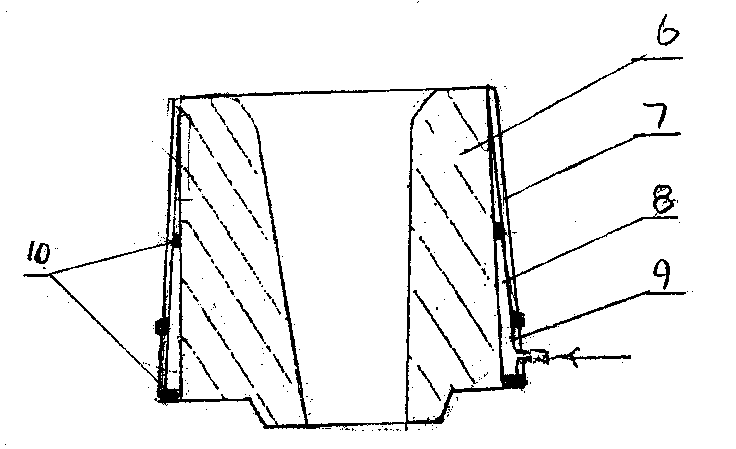

[0028] Such as figure 2 As shown, the continuous casting tundish has a ventilating upper nozzle, including a ventilating hollow truncated cone upper nozzle brick 6, an upper steel sleeve 7, and a lower steel sleeve 9. There is an upper steel sleeve 7 and a lower steel sleeve 9 on the outside of the brick 6, and there is a gap between the outer side of the upper nozzle brick 6 and the inner side of the upper steel sleeve 7 and the lower steel sleeve 9, forming an air passage 8 for ventilation. 6. The outer side is bonded to the inner side of the upper steel sleeve 7 and the lower steel sleeve 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com