Positive-electrode material of metal hydride nickle sealed secondary cell

A technology of secondary battery and positive electrode material, which is applied in the direction of alkaline battery electrode, secondary battery, airtight battery, etc. problems such as service life and internal resistance, to achieve the effect of extending cycle life, excellent high-rate discharge performance, and reducing ohmic internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

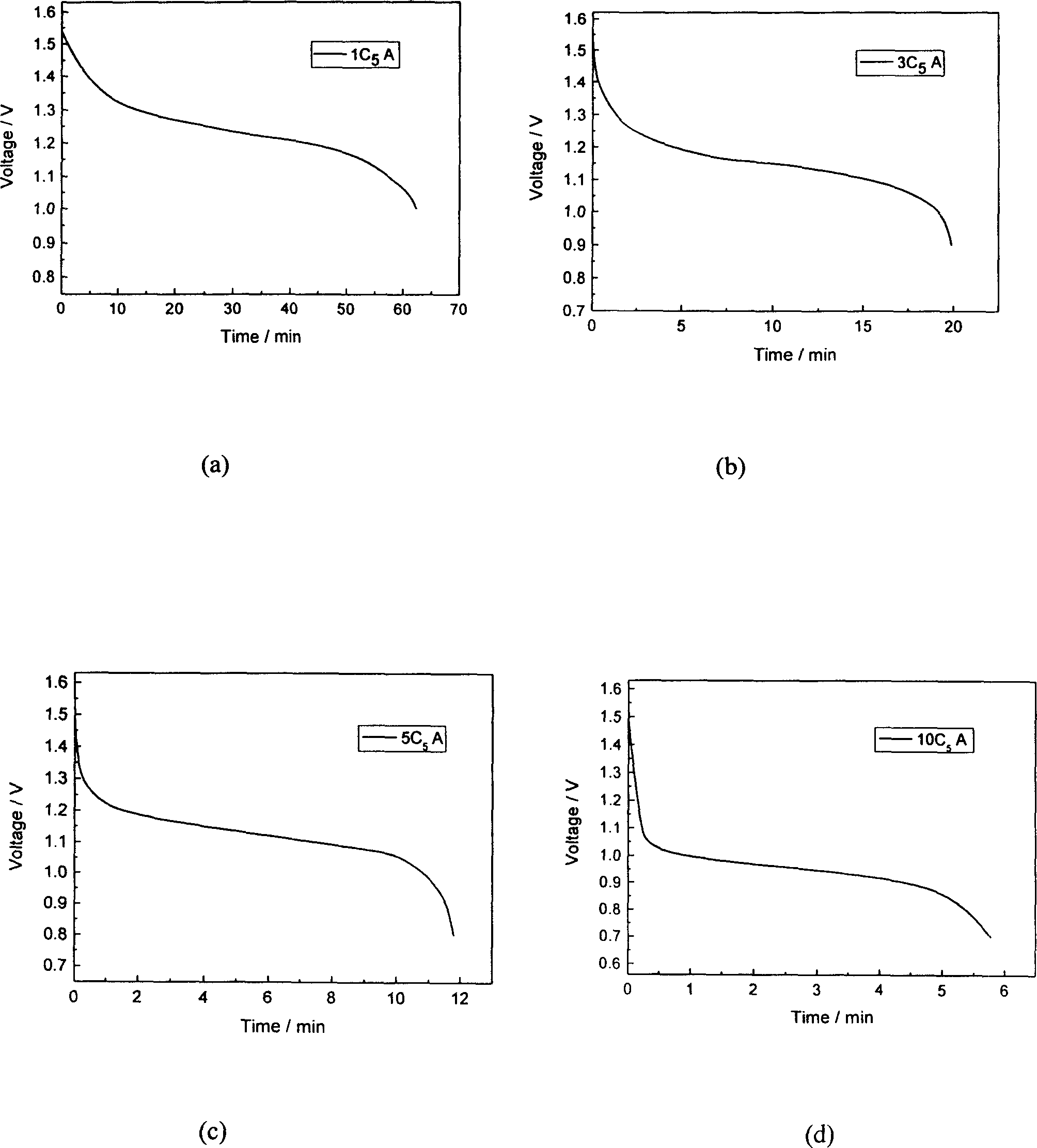

[0011] The positive electrode material composition of the metal hydride nickel sealed alkaline secondary battery contains (by weight): 0.8% multi-walled carbon nanotubes (CNTs), 6.4% CoO, 0.7% Co, remaining β-Ni(OH) 2 . Composition of multi-walled carbon nanotubes and spherical β-Ni(OH) 2 , CoO and Co powders were mixed in proportion, and after ultrasonic oscillation and mechanical stirring for 60 min, the multi-walled carbon nanotubes, CoO and Co powders were mixed in β-Ni(OH) 2 Evenly dispersed in the powder. After adding a small amount of CMC and PTFE binders and water, the uniformly mixed powder is coated on the nickel foam of the current collector, dried and pressed to prepare positive electrodes of different sizes.

[0012] Cut the nickel foam positive plate into shape, the size is: 86×40×0.66mm 3 ; The negative electrode is dry pressed and formed on the copper grid to add oxygen catalyst AB 5 Type hydrogen storage alloy, the excess capacity of the negative electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com