Method for preparing negative electrode material lithium titanate of lithium ion battery through alternating voltage method

A lithium-ion battery, AC voltage technology, applied in battery electrodes, titanate, alkali metal titanate, etc., can solve the problem of poor high-power charging and discharging capacity of lithium titanate, and achieve excellent cycle performance and excellent high rate. Discharge performance, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

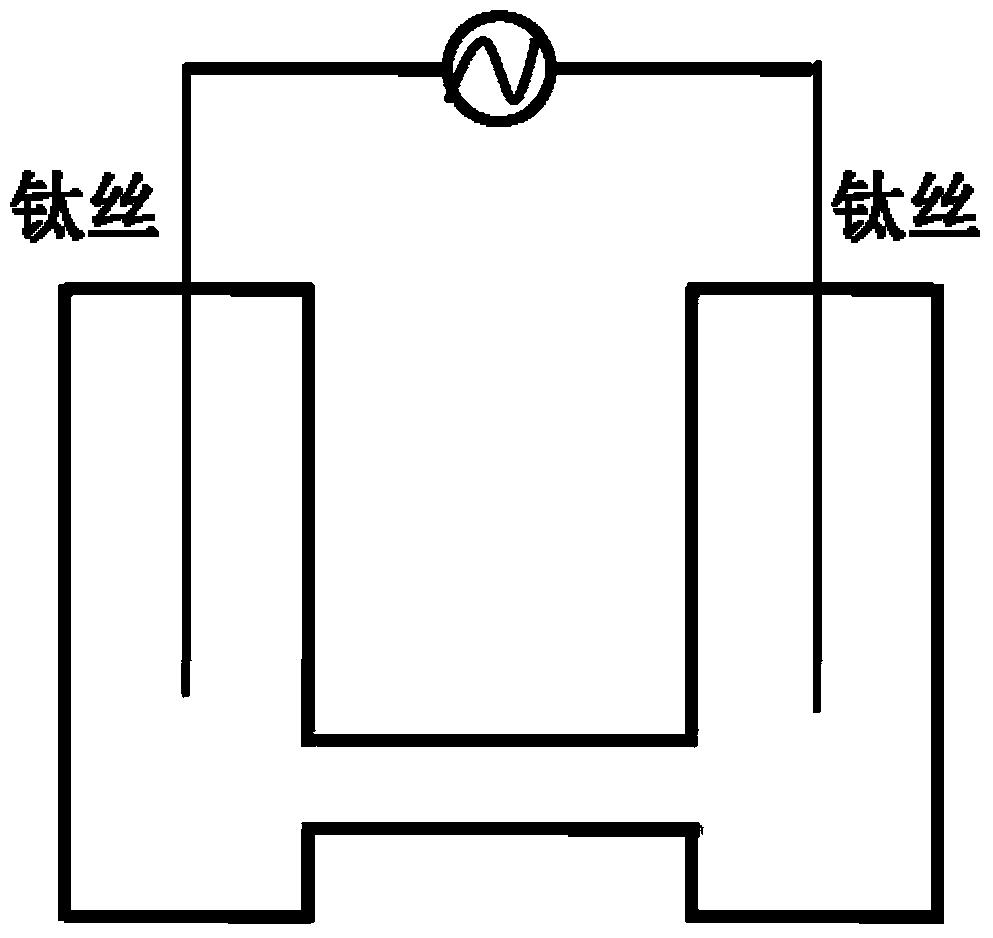

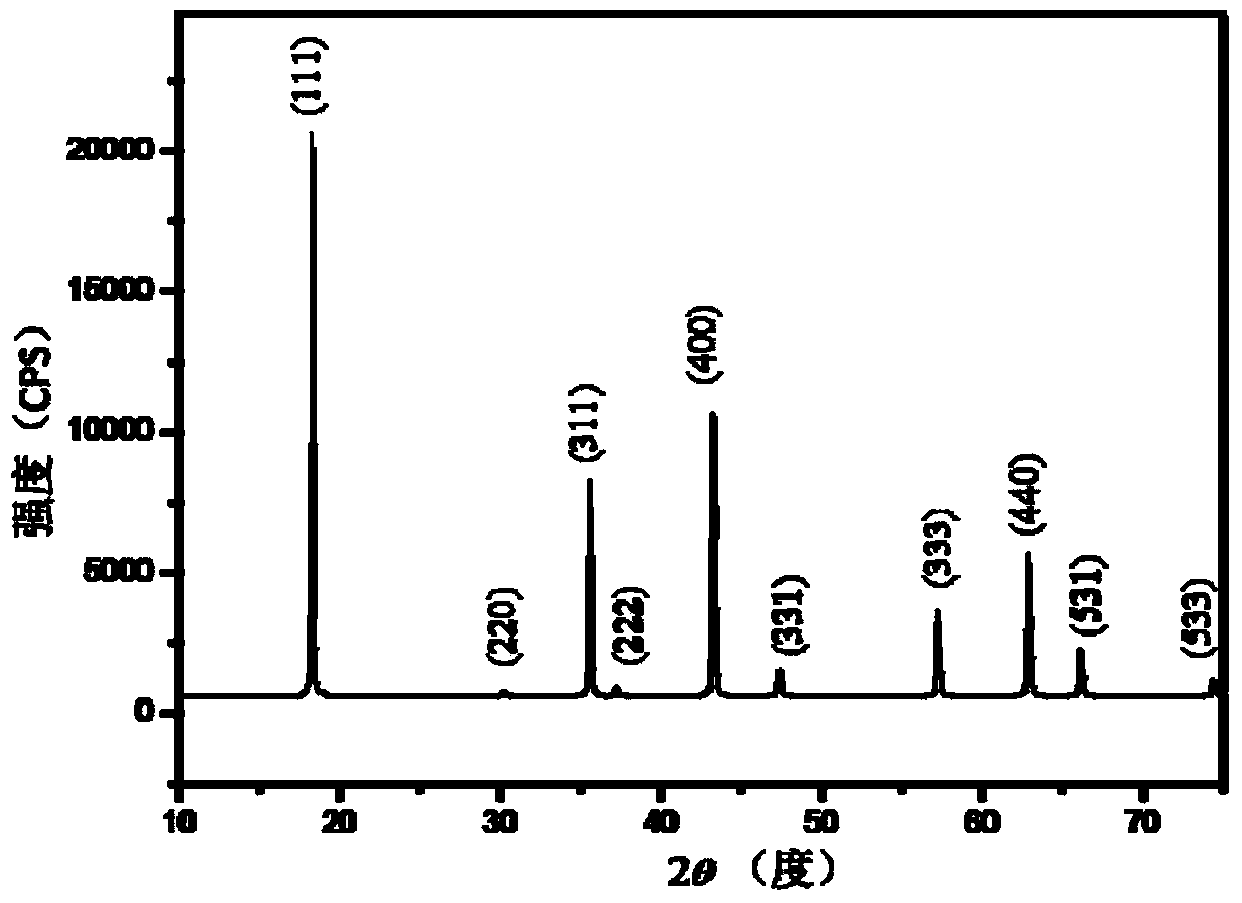

[0029] Such as figure 1 Shown, with 3mol / L NaNO 3 The solution is an electrolyte solution, using pure metal titanium wire as the cathode and anode, applying an AC voltage of 30V for 5 hours, and the metal titanium is dispersed into a titanium oxide nanoparticle sol with a particle size of less than 100nm, and then the titanium oxide sol is separated by suction filtration, and deionized Rinse six times with water, dry at 50°C, and Li 2 CO 3 Mix uniformly according to the molar ratio of lithium to titanium of 0.85, heat treatment at 800° C. for 15 hours in a tube furnace to obtain lithium titanate. From figure 2 And the XRD standard card JCPDS49-0207 shows that the synthesized lithium titanate is a pure phase without other impurities. TEM ( image 3 ) shows that the synthesized lithium titanate particle size is 50-70nm.

[0030] Lithium titanate powder, conductive agent acetylene black and binder PVDF (dissolved in N-methylpyrrolidone) are mixed and ground into a uniform ...

Embodiment 2

[0034] Such as figure 1 Shown, with 3mol / L NaNO 3 The solution is an electrolyte solution, using pure metal titanium wire as the cathode and anode, and applying an AC voltage of 60V for electrolysis for 2 hours (the reaction speed is faster than that of Example 1), the metal titanium is dispersed into a titanium oxide nanoparticle sol, and then the titanium oxide sol is separated by suction filtration , rinsed six times with deionized water, dried at 50 °C and combined with Li 2 CO 3 Mix uniformly according to the molar ratio of lithium to titanium of 0.85, heat treatment at 800° C. for 15 hours in a tube furnace to obtain lithium titanate. TEM ( Figure 7 ) showed that the synthesized lithium titanate was seriously agglomerated, with a particle size of about 30-65nm.

Embodiment 3

[0036]Using 3mol / L NaCl solution as the electrolyte solution, using pure metal titanium wire as the cathode and anode, and applying an AC voltage of 30V for 1 hour, the metal titanium is dispersed into a titanium oxide nanoparticle sol. Ultrasonic collection and cleaning, and other follow-up preparation process with embodiment 1. TEM ( Figure 8 ) shows that the synthesized lithium titanate has a particle size of 40-70nm and some agglomeration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com