Storage battery agm separator and preparation method thereof, storage battery

A battery and separator technology, applied in the field of battery AGM separator and its preparation, can solve the problems of poor electrolyte retention, easy delamination, insufficient resilience, cycle discharge attenuation, etc., to improve battery capacity and high rate. Effects of discharge capacity, reduction of wetting shrinkage and compressibility, acid absorption and wettability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

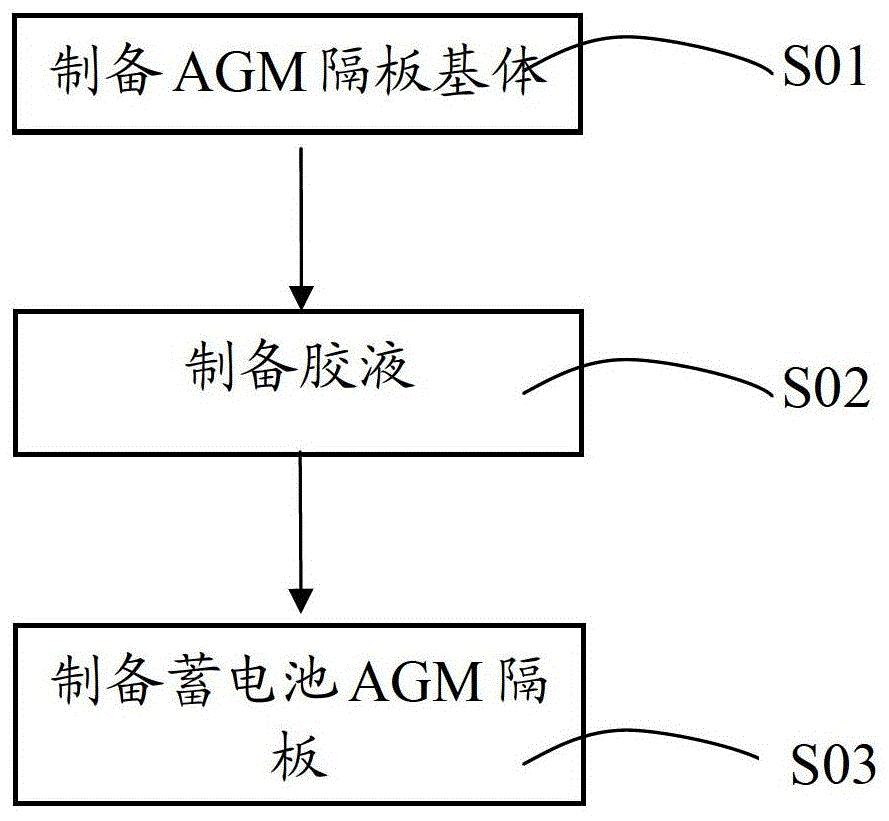

[0038] Correspondingly, the embodiments of the present invention provide a method for preparing battery AGM separators with simple process, easy controllable conditions, and easy industrial scale production. The process flow of this method is as figure 1 As shown, it includes the following steps:

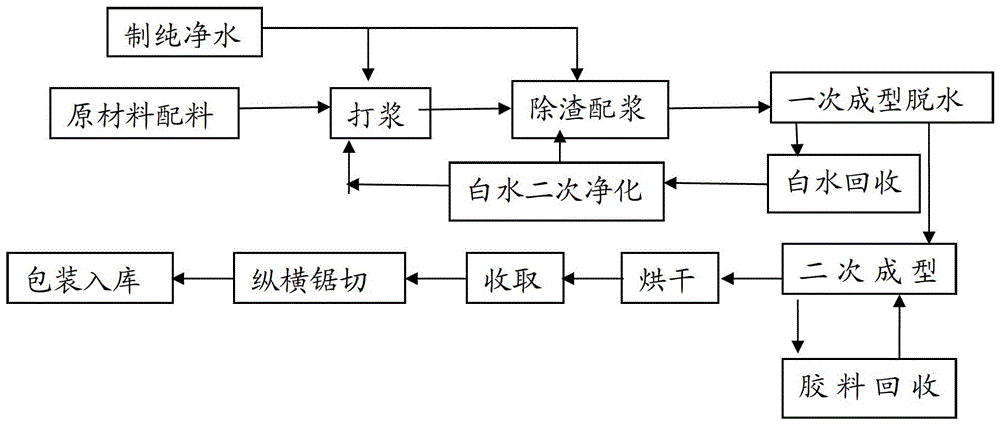

[0039] S01: Mix the high-alkali glass wool, medium-alkali glass fiber, and two-component polyester fiber in proportion to prepare a slurry, and then prepare the AGM separator base according to the AGM separator preparation process;

[0040] S02: Add the above-mentioned SiO 2 The glue of the particles is prepared into a glue solution with a concentration of 1.6~2.0% or 1.9~3.0%;

[0041] S03: Coating the glue solution on the surface of the AGM separator substrate for infiltration treatment, and then performing vacuum negative pressure light dehydration treatment, pressure roller treatment, vacuum strong dehydration treatment, secondary pressure roller treatment and drying treatment...

Embodiment 1

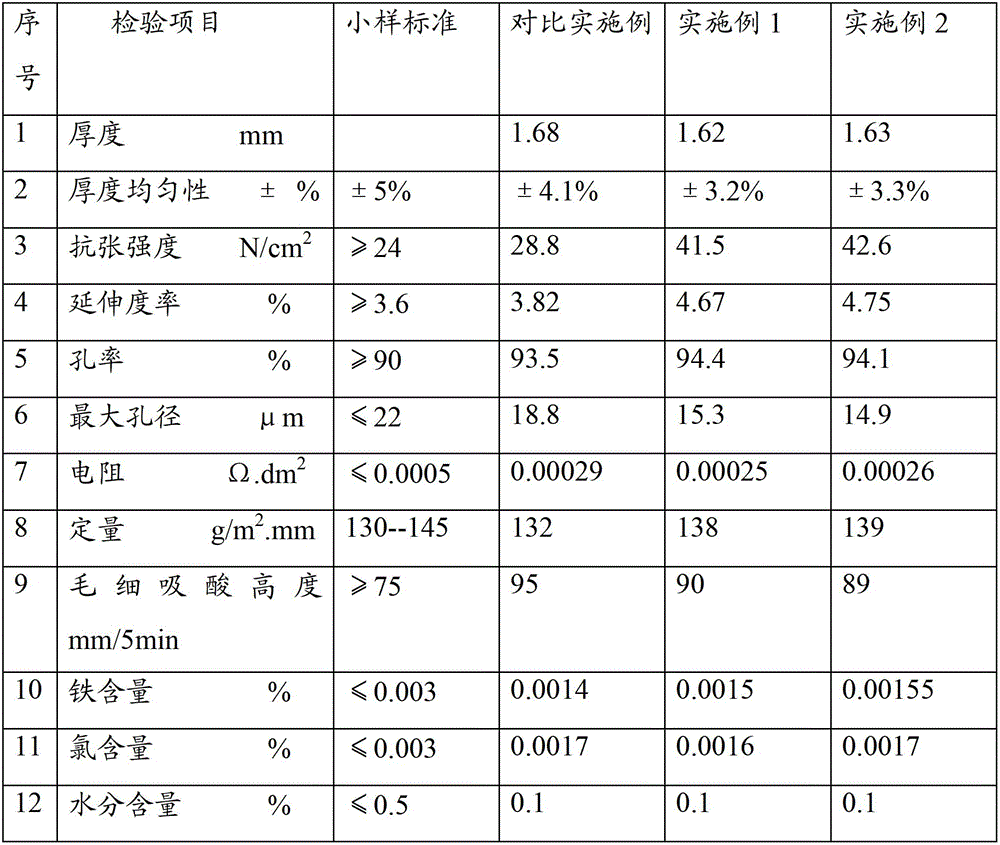

[0053] The present embodiment storage battery AGM separator comprises high-alkali glass wool, medium-alkali glass fiber, two-component polyester fiber, glue, and the weight percent of this high-alkali glass wool, medium-alkali glass fiber, two-component polyester fiber, glue is 86:3.6:2.0:8.4; wherein the colloid contains silica sol, silicon dioxide, and dispersant, and the weight ratio of the silica sol, silicon dioxide, and dispersant is 80:6.7:13.3; high-alkali microfiber glass wool includes an average diameter 1.1μm shielding fiber, skeleton fiber with an average diameter of 2.65μm; medium-alkali glass fiber with a fixed diameter of 9μm and a fixed length of 10mm; two-component polyester fiber with a length of 5mm, an outer diameter of 15μm, and a core diameter of 9μm .

[0054] The preparation method of this storage battery AGM separator is as follows:

[0055] S11: Use an electronic balance (accuracy 1.0%) to accurately weigh 10g of various fibers in proportion, add the...

Embodiment 2

[0060] The present embodiment storage battery AGM separator comprises high-alkali glass wool, medium-alkali glass fiber, two-component polyester fiber, glue, and the weight percent of this high-alkali glass wool, medium-alkali glass fiber, two-component polyester fiber, glue is 83.5:3.5:2.0:11. Wherein the glue solution comprises water-based acrylic latex, wetting agent, silane coupling agent, precipitated silica, micron silica, the water-based acrylic latex, wetting agent, silane coupling agent, precipitated silica, micron silica The weight ratio of the high-alkali microfiber glass wool is 67:12:0.2:16:4.8; the high-alkali microfiber glass wool includes shielding fibers with an average diameter of 1.1 μm and skeleton fibers with an average diameter of 2.65 μm; The length is 10mm; the length of the two-component polyester fiber is 5mm, the outer diameter is 15μm, and the core diameter is 9μm.

[0061] The preparation method of this storage battery AGM separator is as follows:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com