Potential oil screw pump production system

A technology of oil production system and submersible screw, which is applied in the fields of production of fluid, earth-moving drilling, wellbore/well components, etc., can solve the problems of reducing the pump efficiency of the screw pump, the wear of the parts of the motion conversion mechanism, and the large size of the structure. The effect of energy consumption, ensuring normal operation, and enhancing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

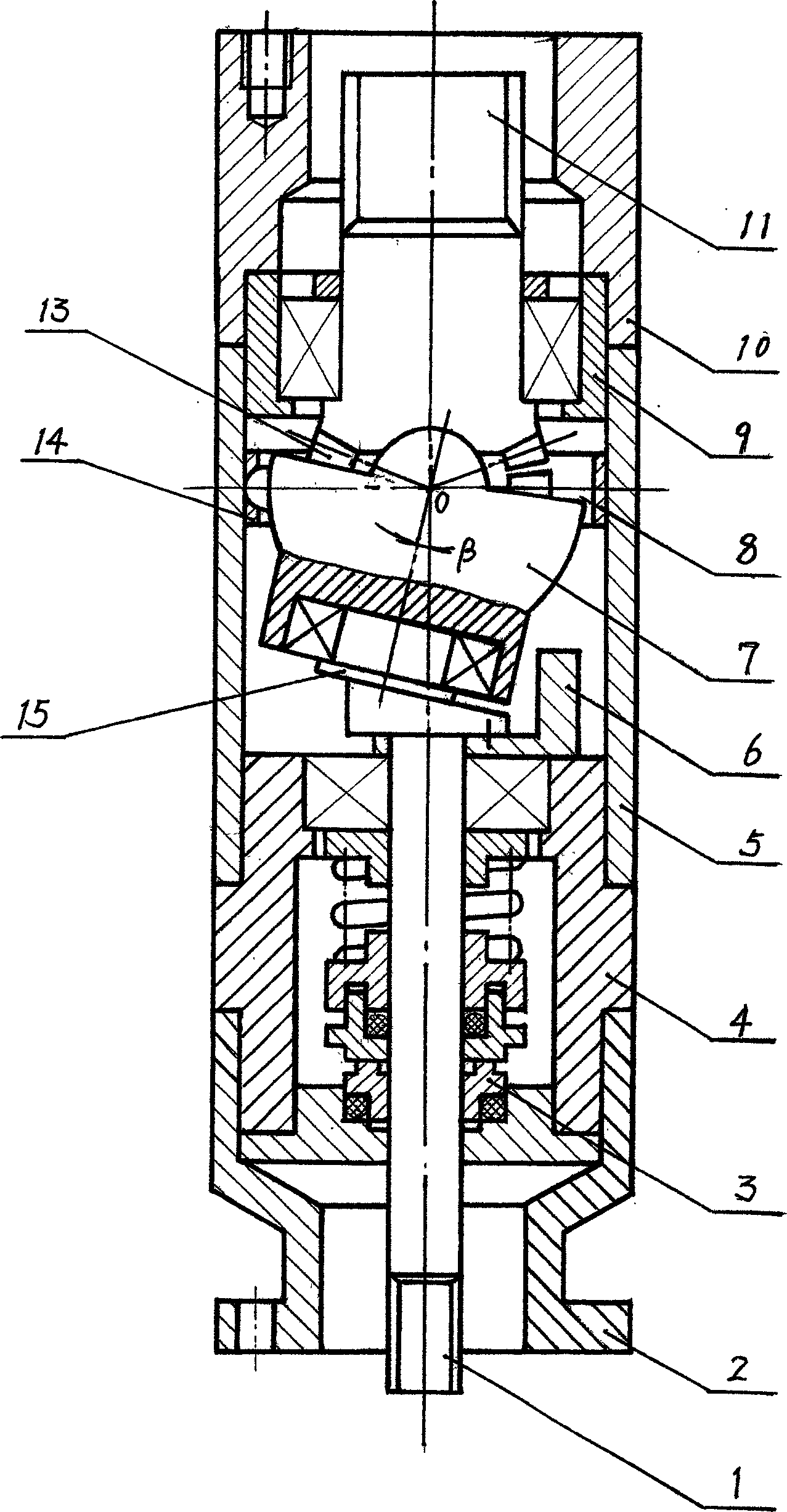

[0037] Figure 8It shows a structural schematic diagram of a submersible screw pump oil production system of the present invention, which includes a submersible motor 201 and a motor protector connected sequentially from bottom to top by using the connecting flange or the coupling and spline structure in each device 202, reducer 203, reducer protection device 204, screw pump 206 and oil production system protection device 207, the power between the surface power supply and the submersible motor 201 is transmitted by the submersible motor special cable 211, and the A plurality of cable clips 208 may be arranged on the special cable 211 for the submersible motor of nearly one thousand meters according to the requirement, and the system protection device 207 is connected with the oil pipe 210 through the oil pipe joint 209 .

[0038] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com