Horizontal type detector of atom force microscope

An atomic force microscope, horizontal technology, applied in the field of atomic force microscope probes, can solve the problems of restricting the popularization and application of AFM, restricting the development and popularization of nanotechnology, and expensive operation requirements, etc., and it is easy to realize the technical conditions, good nanometer detection and imaging performance, Improvement of action efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The core component of the atomic force microscope is a probe composed of a scanning and feedback controller and a photoelectric detection system, which directly affects the detection resolution, detection accuracy, scanning range, and signal-to-noise ratio of the atomic force microscope. The purpose of the present invention is to invent a horizontal atomic force microscope probe, so that the atomic force microscope system can obtain better nanometer detection performance.

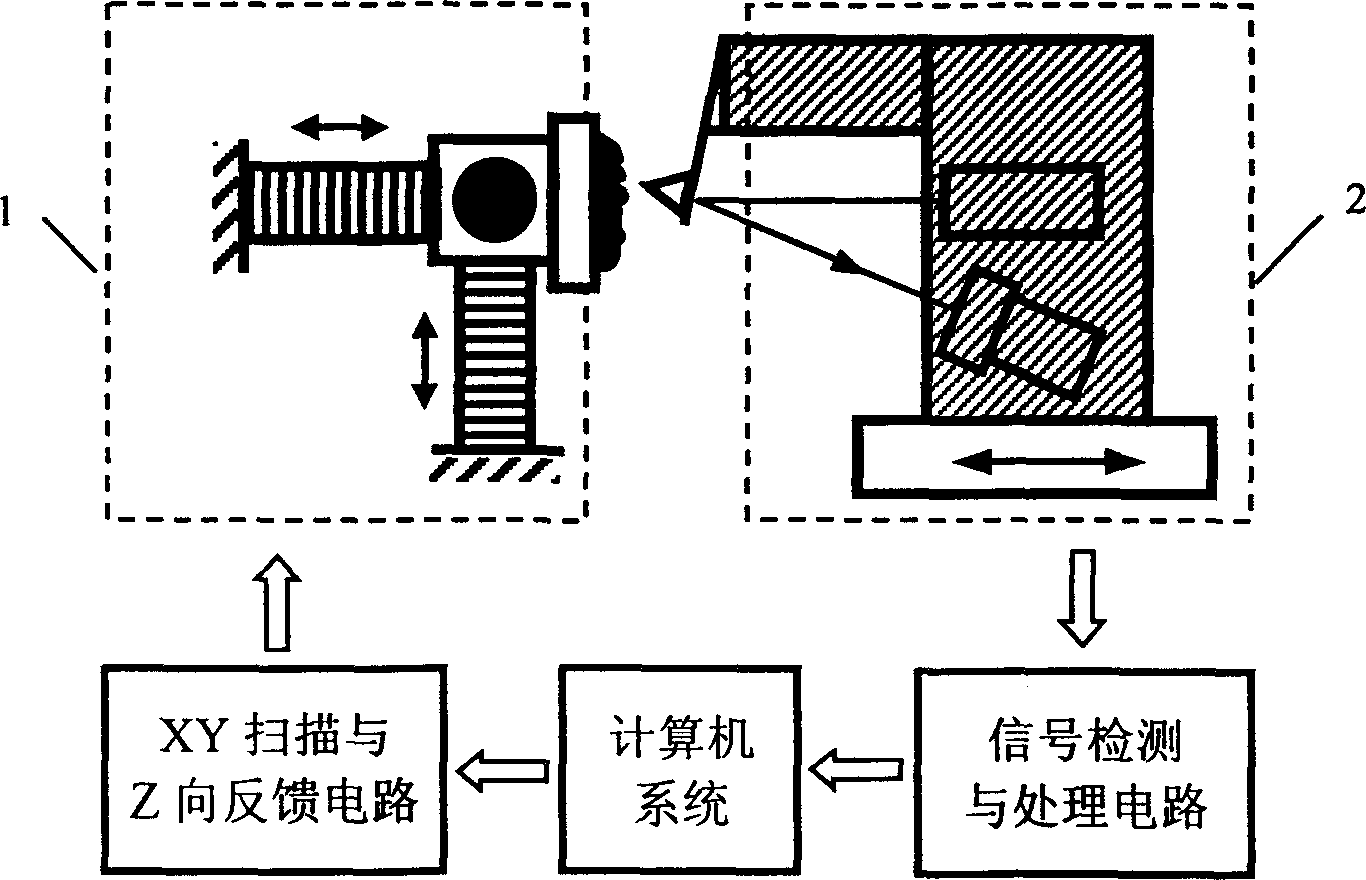

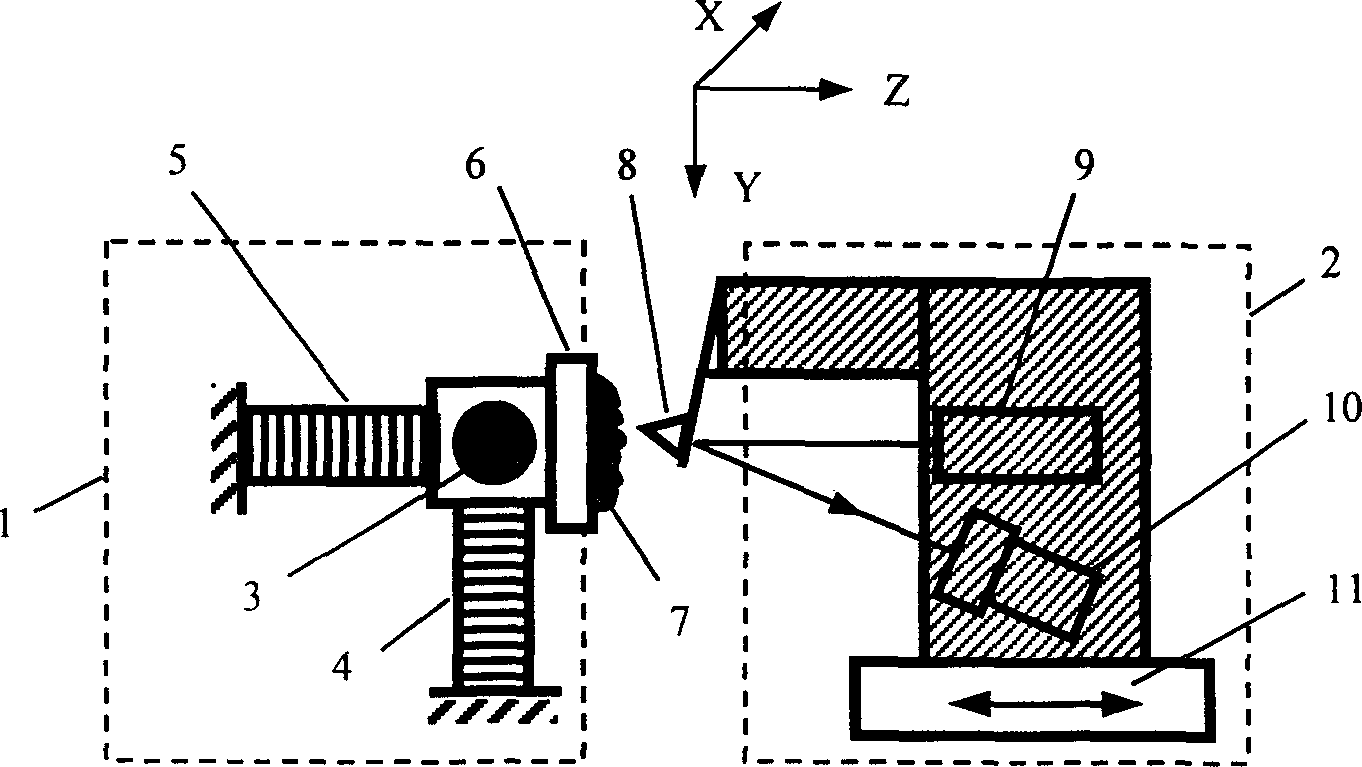

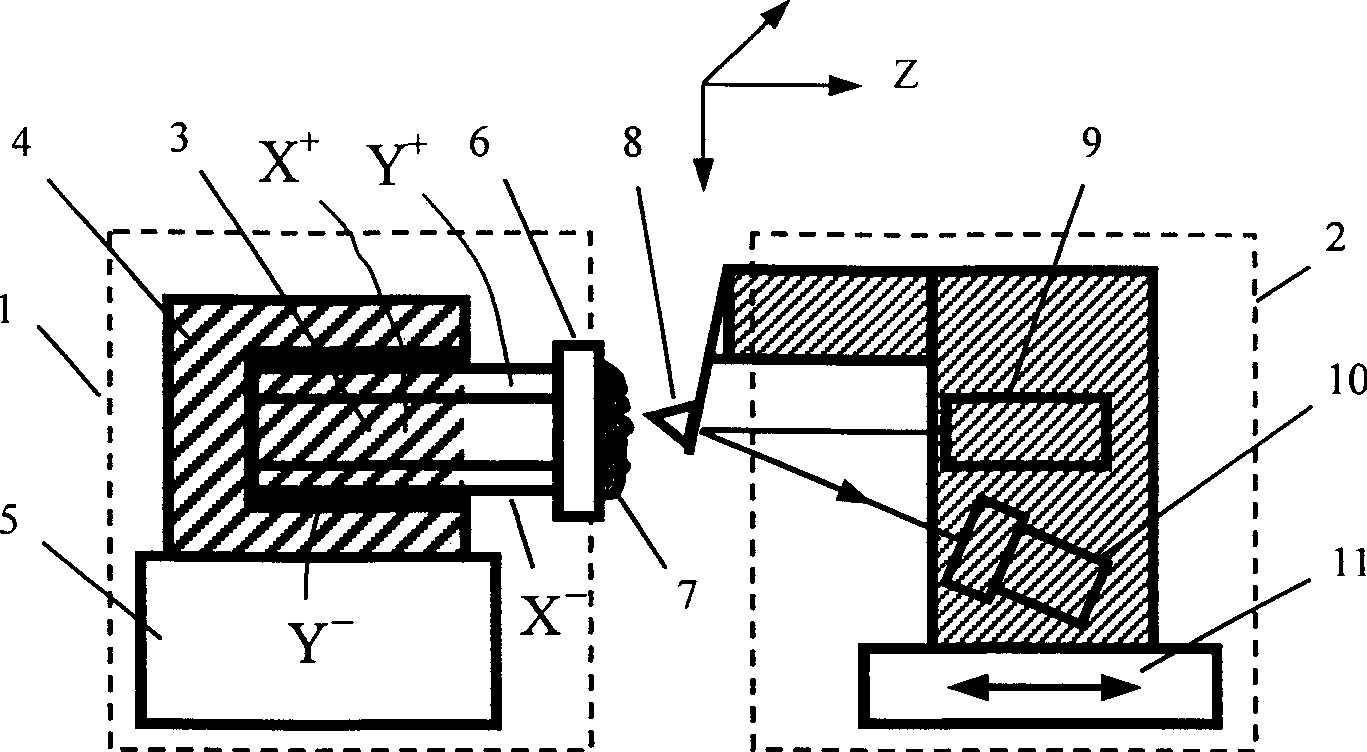

[0010] figure 1 Shown is a schematic diagram of the working principle of a horizontal atomic force microscope. The horizontal atomic force microscope probe of the present invention includes two parts: a scanning and feedback controller 1 composed of XYZ piezoelectric ceramics and a sample stage, and a photoelectric detection system 2 composed of a microcantilever probe, a laser and a position sensitive device (PSD). . AFM uses a microcantilever that is extremely sensitive to weak forces as a force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com