Accumulation of heat typed high temperature air burning device and its methods

A high-temperature air and combustion device technology, which is applied in the field of high-temperature air combustion, can solve problems such as fire failure and deflagration, and achieve the effects of reducing oxidation burning loss, fast heating, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

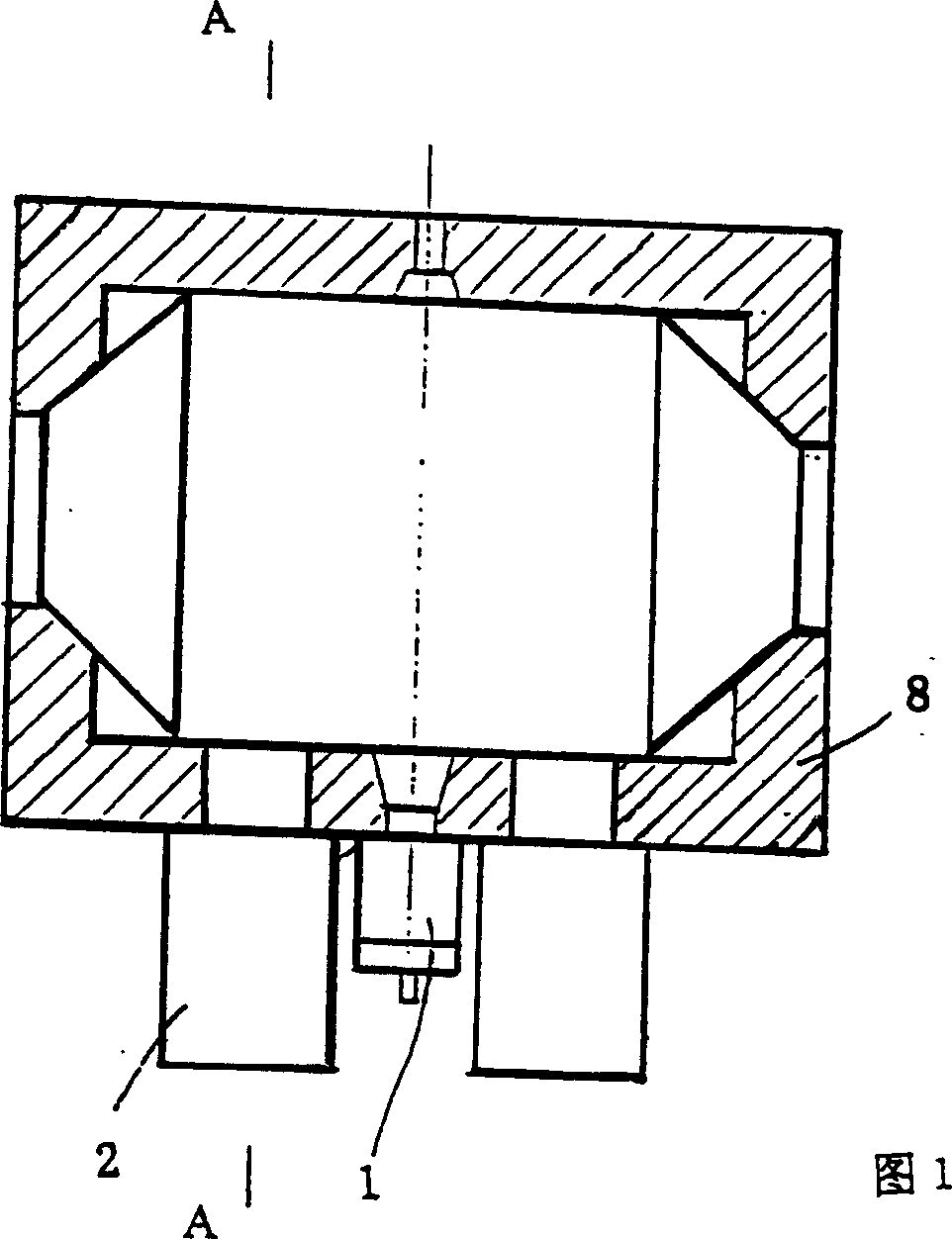

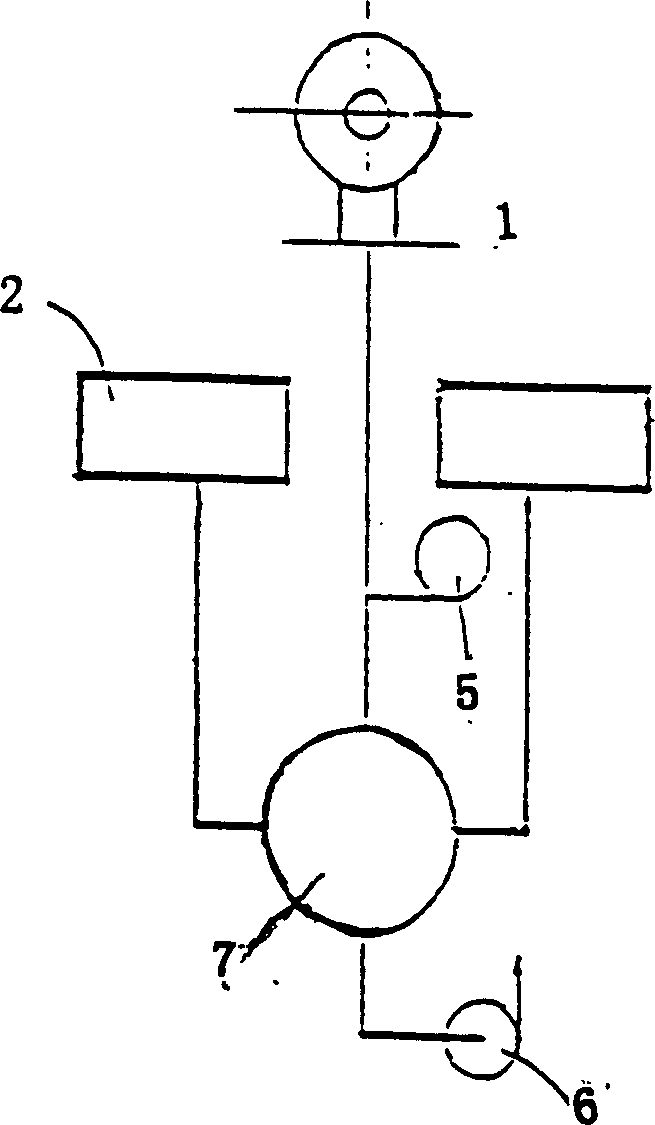

[0025] Referring to Fig. 1, the regenerative high-temperature air combustion device of the present invention includes a furnace body 8, on which at least one fuel nozzle 1 for injecting fuel and at least two burner bricks connected with the furnace body 8 are arranged. 4 connected at least two regenerators 2, the regenerator 2 blows combustion air into the furnace and induces flue gas in the furnace to store heat for the regenerator. Therefore, the fuel supply system and the heat storage system are separated from each other, the fuel is continuously supplied by the fuel nozzle 1, and the combustion-supporting hot air is alternately supplied by the two heat storage chambers 2 to ensure that the temperature of the hot air is 800°C (100°C lower than the furnace temperature) -200°C) or so.

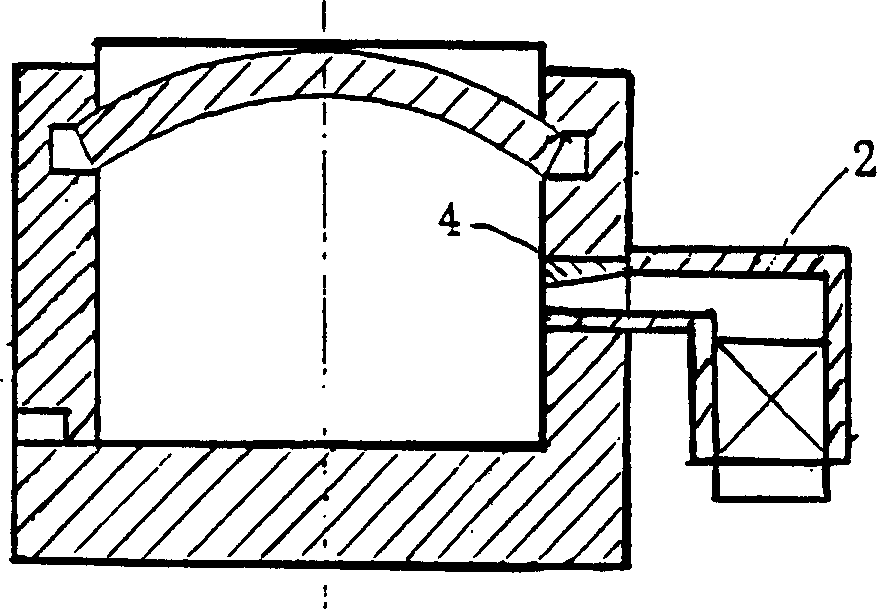

[0026] see figure 2 , the combustion-supporting hot air fed into the regenerator 2 enters the combustion chamber through the through hole of the burner brick 4 . The upper plane of the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com