Foaming agent for earthwork

A technology of foaming agent and foam stabilizer, which is applied in applications, household appliances, and other household appliances, etc., can solve the problems of limited raw material resources, complicated preparation process, unstable performance, etc., and achieve simple preparation process, wide application range, The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

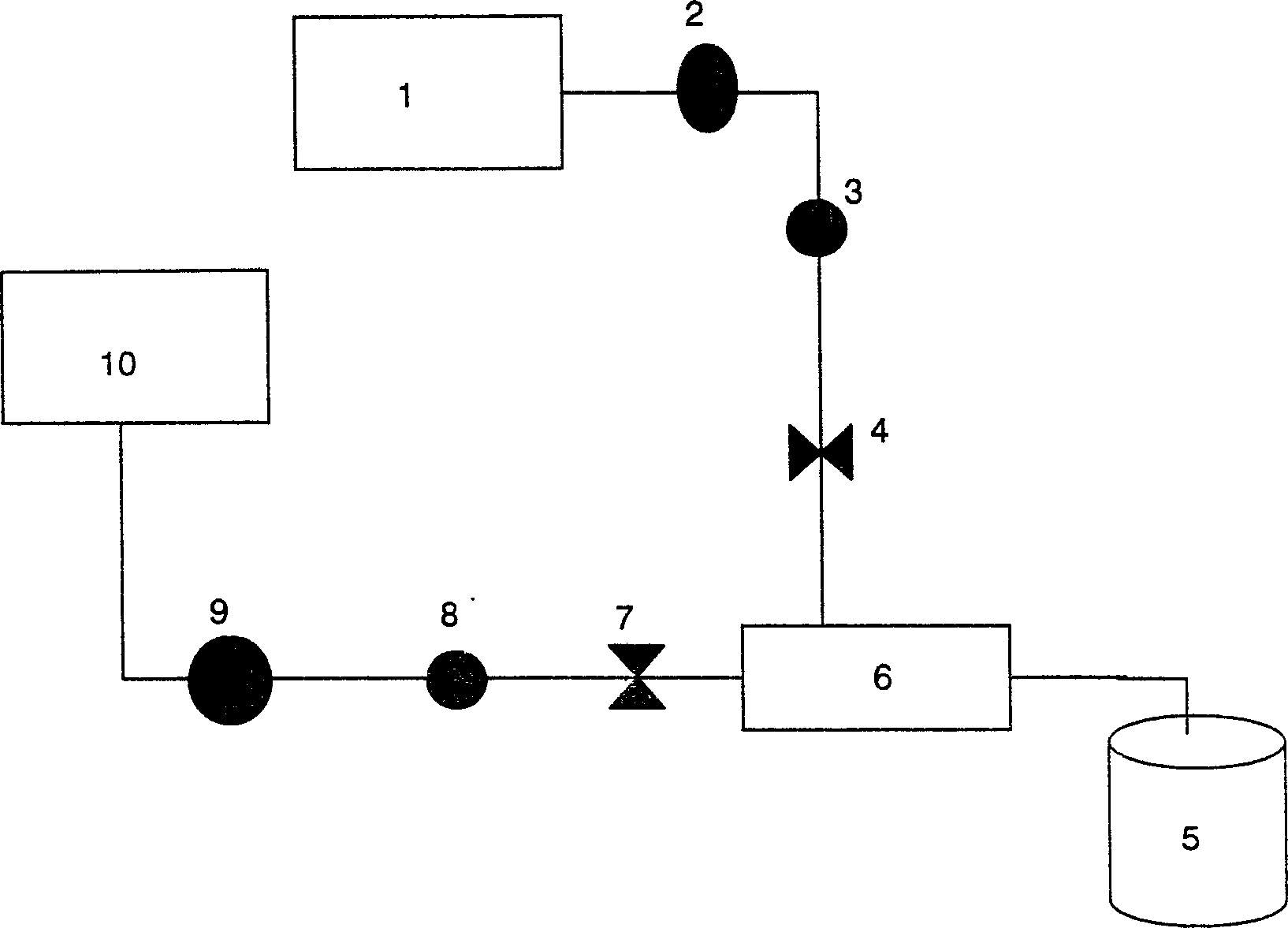

Image

Examples

Embodiment 1

[0024] Compounding sodium lauryl sulfate with alkanolamide and auxiliary agent calcium chloride can obtain a foaming agent with high foaming efficiency and good foam stabilizing performance. The weight percentage is:

[0025] Lauryl Sulfate 5%

[0026] Alkanolamide 2.5%

[0028] Water 91.5%

[0029] When in use, the prepared foaming solution is foamed by a foaming device, and the time required for 50% of foaming and defoaming is 72 minutes. It is suitable for making light materials such as air bubble mixed light soil and foam concrete. Compared with similar foreign products that achieve the same index, the cost is reduced by 30%.

Embodiment 2

[0031] Compounding sodium lauryl sulfate with alkanolamide and fatty alcohol polyoxyethylene ether sodium sulfate, etc., its mass percentage:

[0032] Lauryl Sulfate 5%

[0033] Alkanolamide 4%

[0034] Sodium fatty alcohol polyoxyethylene ether sulfate 4%

[0035] Water 87%

[0036] When in use, the prepared foaming solution is foamed by a foaming device, and the time required for 50% of foaming and defoaming is 15 minutes. It is suitable for soil improvement in the pressure chamber of the shield machine in the earth pressure balance shield tunneling construction. Compared with similar foreign products that achieve the same index, the cost is reduced by 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com