Method for raising production efficiency of delayed coking liquid product

A liquid product, delayed coking technology, applied in cracking, non-catalytic thermal cracking, petroleum industry, etc., can solve the problems of increasing equipment investment, reducing the contribution of coke yield, etc., to reduce equipment investment and reduce coke yield , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

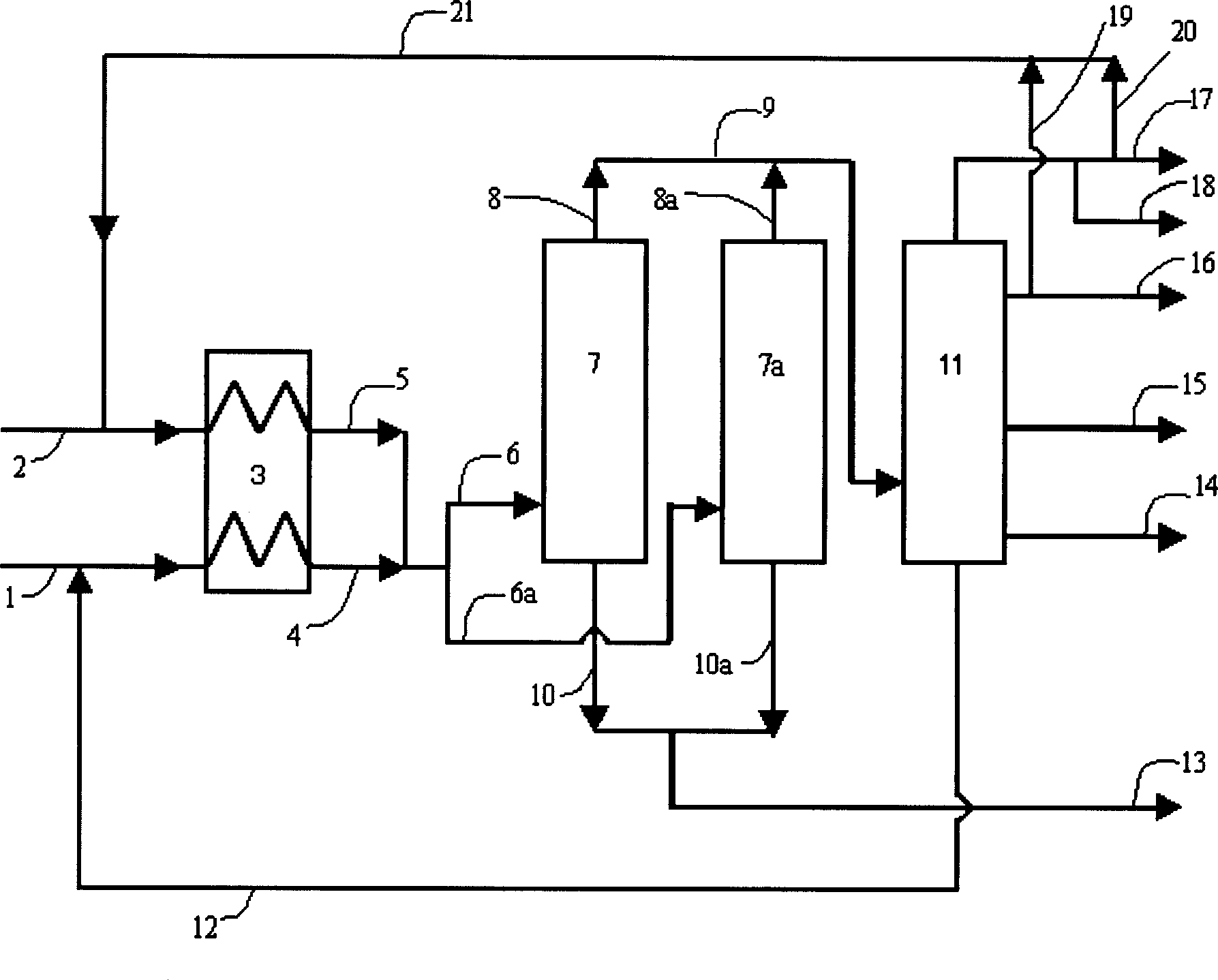

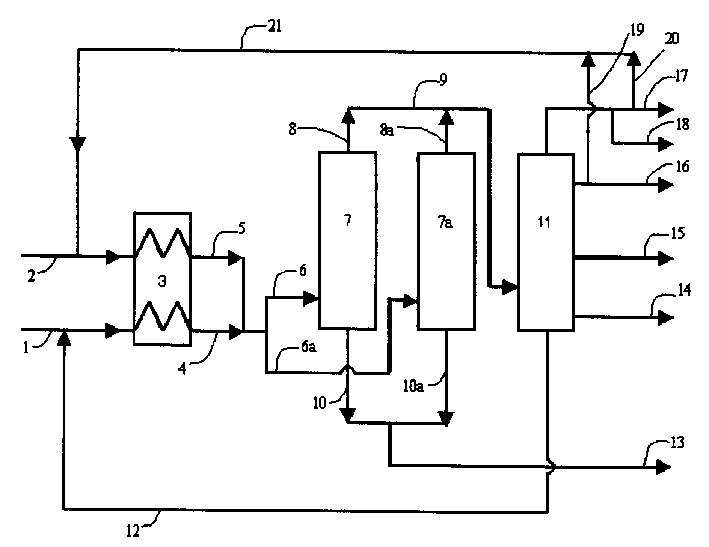

[0025] As shown in Figure 1, the raw oil enters the heating furnace 3 through the pipeline 1 for heating, and the low-molecular hydrocarbon heating agent enters the radiation zone of the heating furnace 3 along the pipeline 2. After being heated to the required temperature, the raw oil and low-molecular The hydrocarbons pass through the pipeline 4 and the pipeline 5 together and enter the coke 7 through the pipeline 6 to undergo a coking reaction. The coking reaction product enters the fractionation tower 11 from the top of the coking tower 7 through the pipeline 8 and the pipeline 9, and the various hydrocarbons are separated in the fractionation tower 11. product. C 1 、C 2 Export device via line 18, C 3 、C 4 A part is exported to the device through the pipeline 17, and the other part is circulated as a heating agent to the high-temperature radiation area of the raw material heating furnace through the pipelines 20 and 21 for recycling; C 5Part of the -180°C distillate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com