Structure of flash memory cell and method for making the same

A technology of storage unit and manufacturing method, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

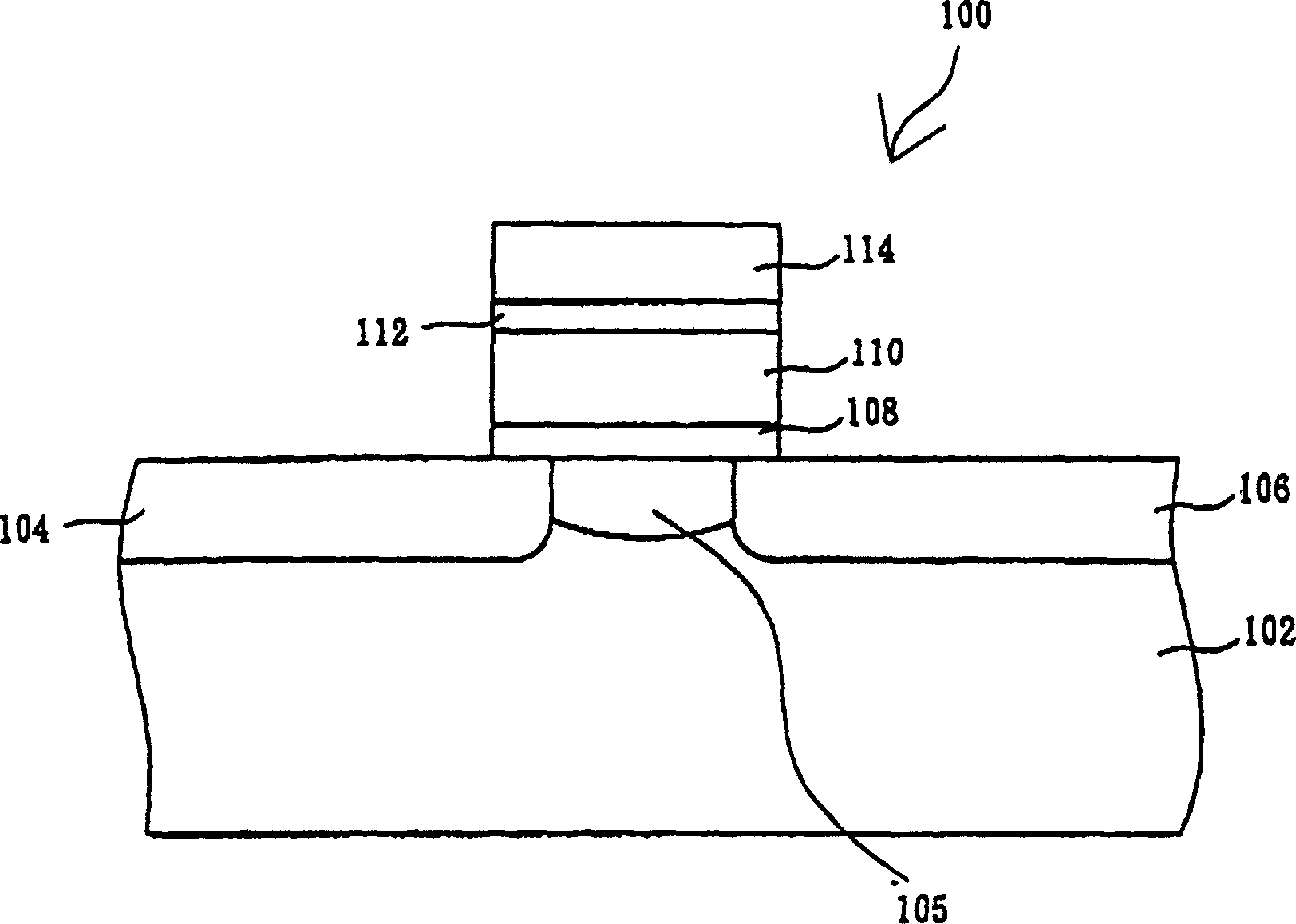

[0032] The invention discloses a structure of a flash storage unit and a manufacturing method thereof. The flash memory unit of the present invention has a planar surrounding gate, and can use FN tunneling effect to write and erase data. In addition to effectively improving the leakage current between the source and the drain and increasing the cell current in the on state, it can also achieve the purpose of improving the performance of the device without increasing the size of the device. In order to make the narration of the present invention more detailed and complete, refer to the following description and cooperate Figure 2 to Figure 15 .

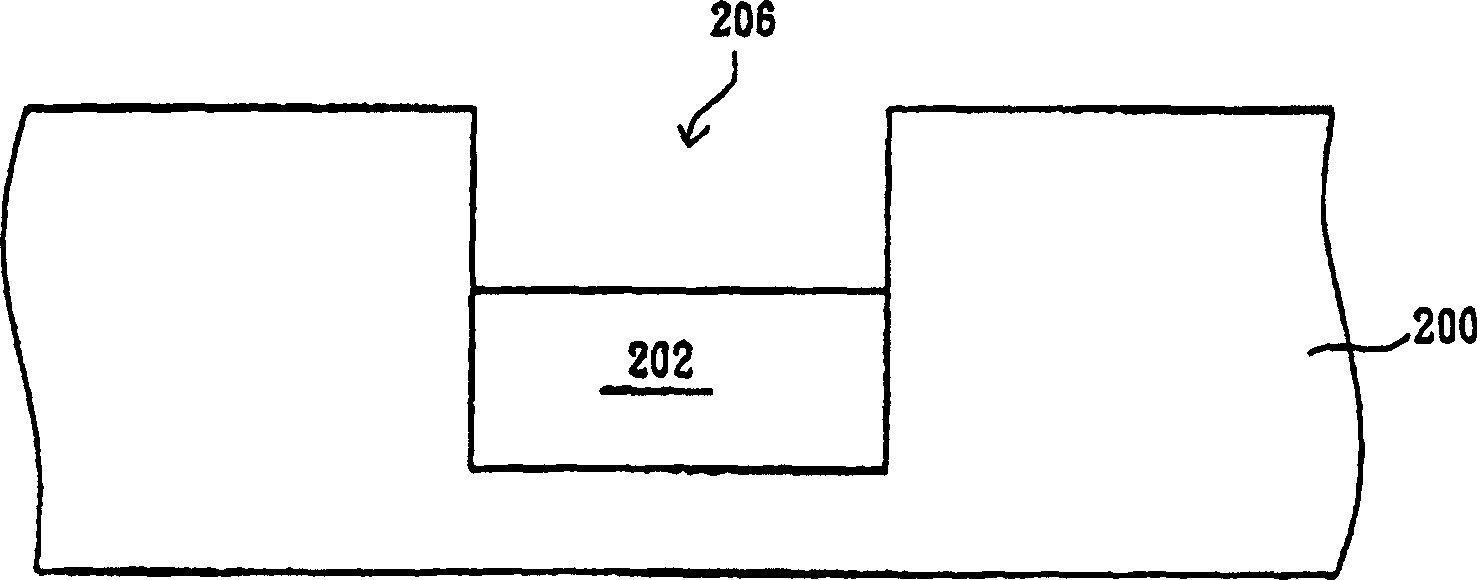

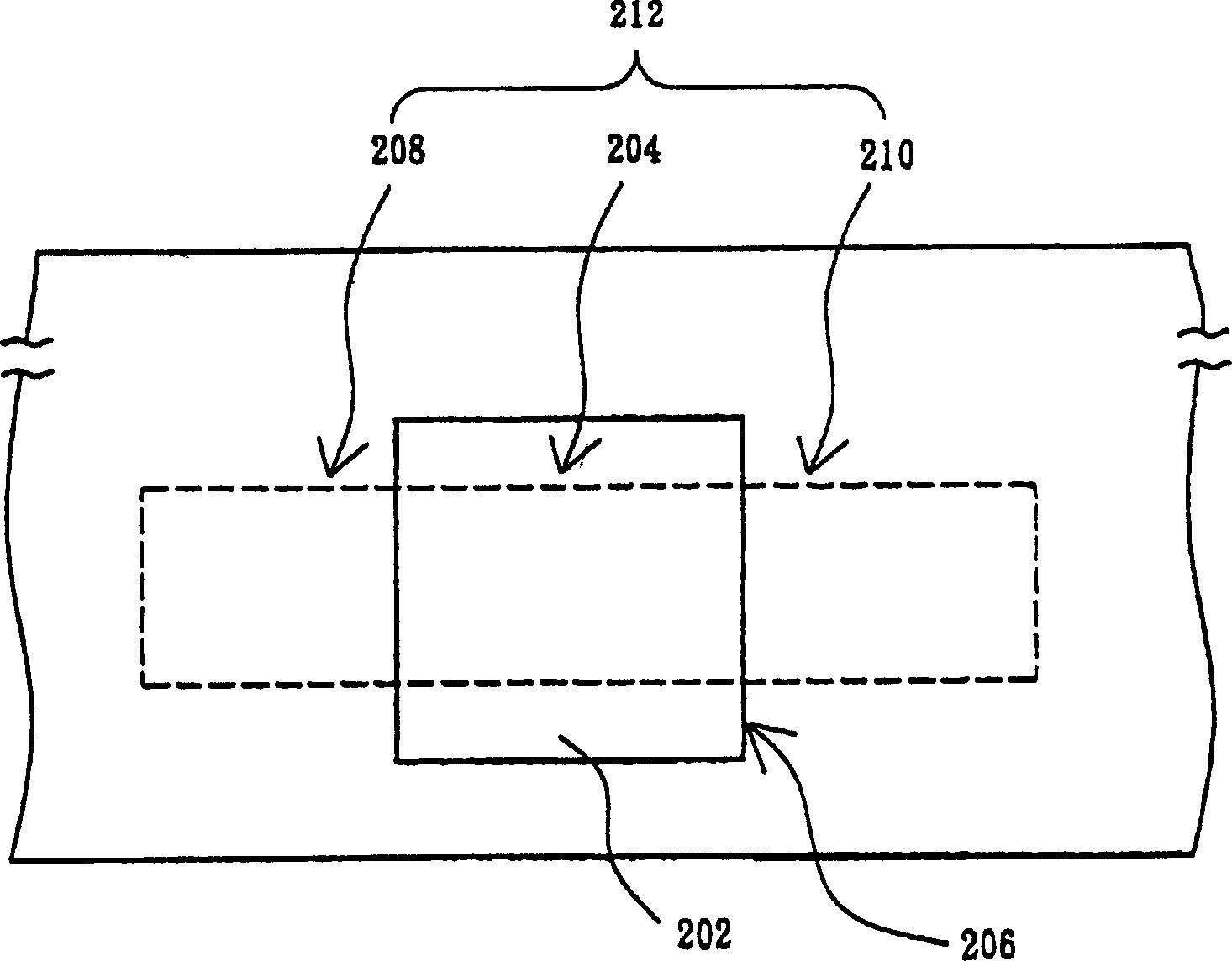

[0033] Please refer to figure 2 and Tutu, where image 3 for figure 2 top view. First, a plurality of isolation regions 202 are formed on the semiconductor substrate 200 (only the isolation regions 202 located in the preset device region 212 are shown), part of the isolation regions 202 are used to isolate devices, and the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com