High-purity pressure-maintaining deep sea hot liquid sampler

A deep-sea hydrothermal, high-purity technology, applied in the direction of sampling devices, etc., can solve the problems of increasing operational difficulty, cost and sampling process complexity, affecting sampling efficiency, affecting sample purity, etc., to achieve automatic control of sampling speed, improve purity, reduce Effects of cost and process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

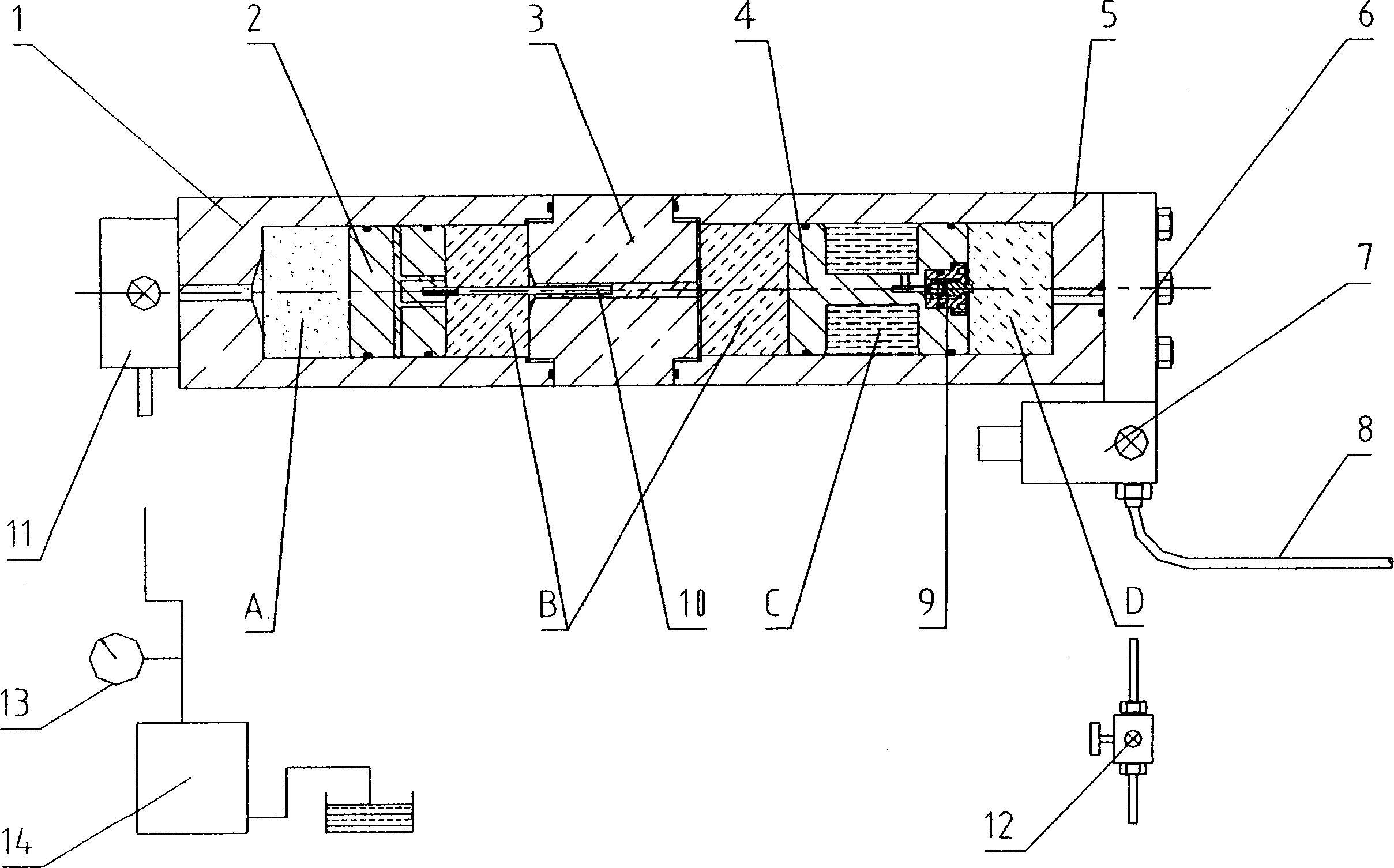

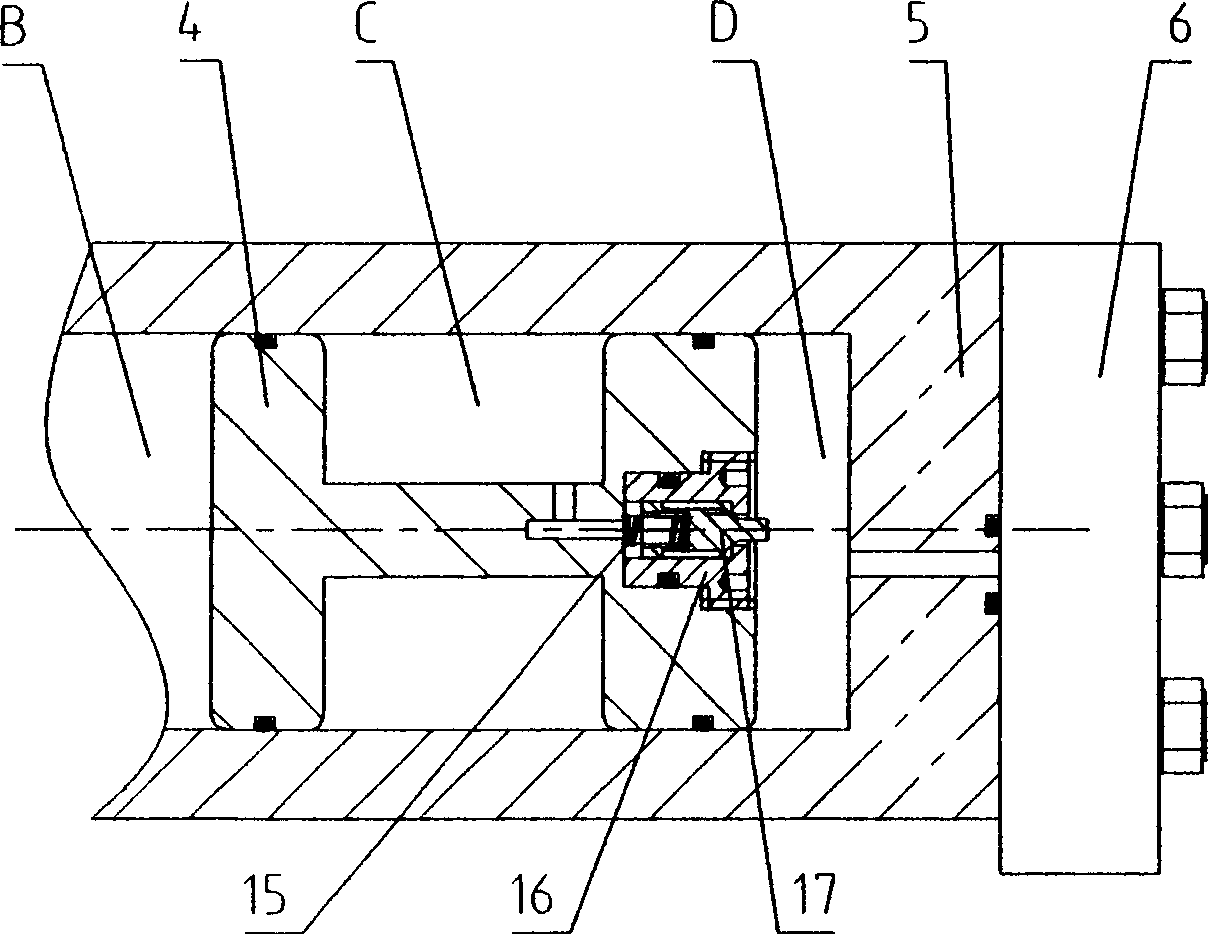

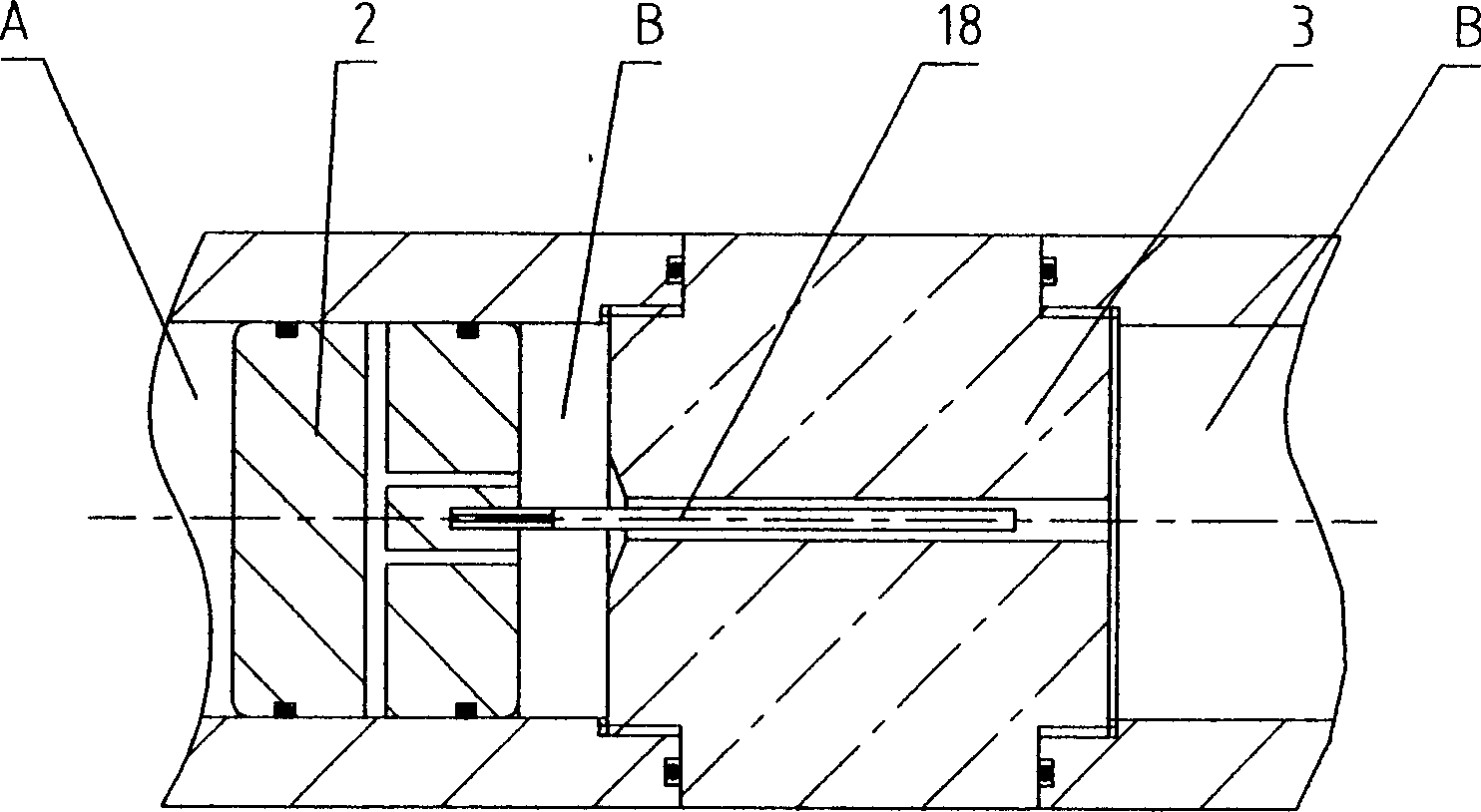

[0017] Such as figure 1 , figure 2 As shown, the present invention includes: pressure storage cylinder 1, pressure storage chamber piston 2, connecting body 3, "I"-shaped sample chamber piston 4, sample cylinder 5, valve plate 6, sampling valve 7, water suction pipe 8, one-way The valve mechanism 9, the variable damping throttling mechanism 10, the inflation valve 11, the micro valve 12, the micro high pressure pump 14, the sample cylinder 5 and the pressure storage cylinder 1 are respectively fixed at the front and rear ends of the connecting body 3, and the inner cavity of the sample cylinder 5 is set The piston 4 of the "I"-shaped sample chamber, the inner cavity of the pressure storage cylinder 1 is provided with the pressure storage chamber piston 2, and the center of the connecting body 3 has an axial small hole, thus respectively forming the pressure storage chamber A, the isolation water chamber B, the pre-suction chamber Cavity C and sample chamber D, a check valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com