Method of preparing hot pressure casting porous ceramic using organic foam micro ball as perforating agent

A technology of organic foam and porous ceramics, applied in ceramic products, other household utensils, household utensils, etc., can solve the problems that the structure of porous ceramics is greatly affected, the control of pore size and channel is not ideal, and the shape and density are not easy to control. Adhesive growth, controllable three-dimensional connected three-dimensional porous structure, beneficial effect of blood vessel and nerve ingrowth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

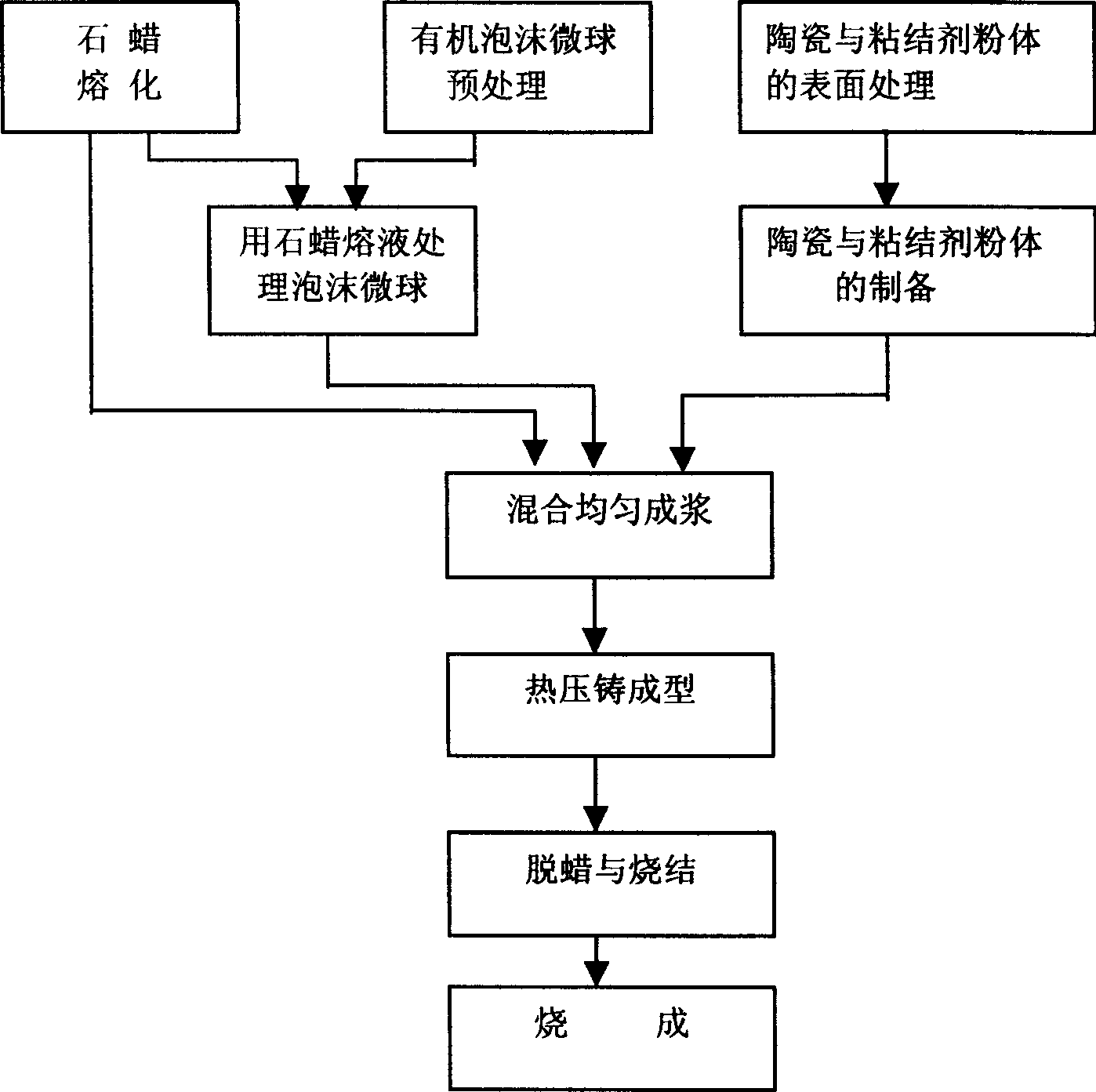

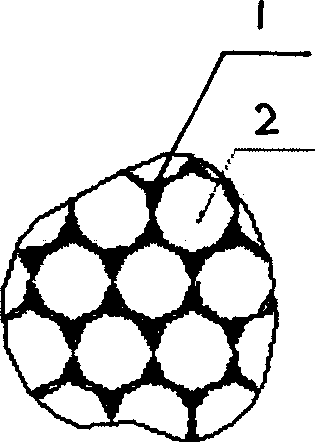

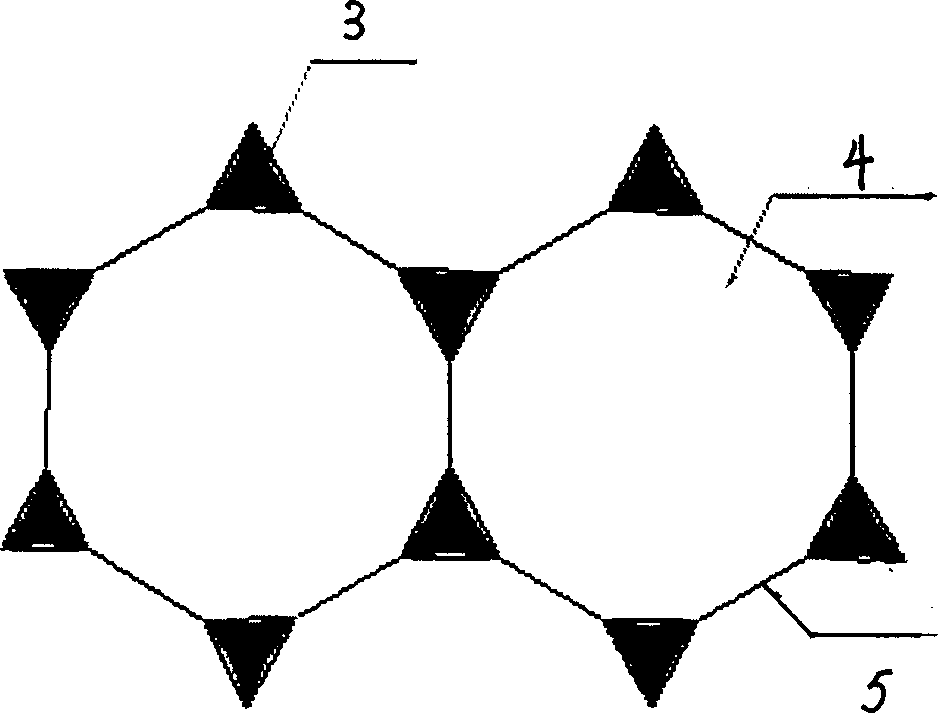

[0041] Ordered and porous β-tricalcium phosphate (abbreviated as β-TCP) bioceramic has been successfully prepared by using the preparation technology of ordered and controllable porous materials. , have good mechanical and processing properties. The specific process is roughly as follows: 1. Treatment of polystyrene foam balls

[0042] First of all, we explored and found an organic substance with a low melting point (40°~70°), which does not intermelt with polystyrene foam balls but can have good wettability with it - sliced paraffin - as a dispersion agent. After the foam balls pass through a 20-mesh sieve and a 30-mesh sieve remains, they are treated with sliced paraffin wax to adjust the surface hydrophilicity and hydrophobicity of the foam balls. 2. Preparation and surface treatment of β-tricalcium phosphate ceramic powder and binder

[0043] Composition of β-tricalcium phosphate ceramic powder and high-temperature biological glass binder (powder) (mass percentage o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com