A nano microbeam cellulose, method for preparing the same and use thereof

A microbial cellulose and nanotechnology, applied in the direction of bacteria, fermentation, and medical raw materials derived from bacteria, etc., can solve problems such as difficult classification, unevenness, and wide particle size distribution of nanocellulose particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

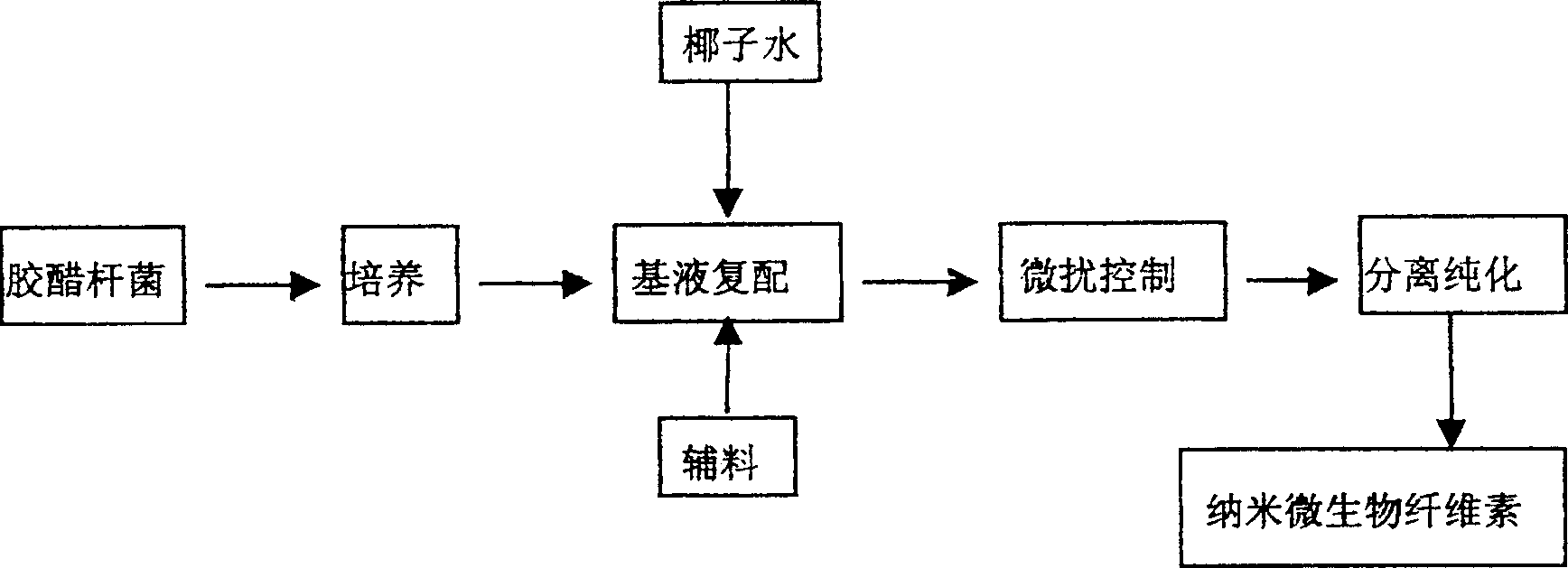

Method used

Image

Examples

Embodiment 1

[0019] Mix 500 grams of coconut water, 3000 grams of pineapple juice, 300 grams of sucrose, 6180 grams of tap water, 5 grams of potassium dihydrogen phosphate and 15 grams of ammonium sulfate to form a solution, adjust the pH value of the solution to 3, sterilize at 110 ° C, cool to 30 ℃, add Acetobacter xylinum CGMCC0603 strain, adjust the pH value to 3 every 2 hours in the incubator, the gas-liquid ratio is 30% (volume ratio), cultivate for 48 hours, and then separate and purify to make nano-microbial fibers Vegetarian 10 mg. Its particle size is 100 nm as tested by electron microscopy (see figure 2 ).

Embodiment 2

[0021] Mix 5000 grams of coconut water, 800 grams of glucose, 4130 grams of tap water, 15 grams of potassium dihydrogen phosphate and 55 grams of ammonium sulfate to form a solution, adjust the pH value of the solution to 6, sterilize at 110 ° C, cool to 25 ° C, add wood vinegar The bacillus CGMCC0603 strain is adjusted to a pH value of 6 every 2 hours in an incubator, and the gas-liquid ratio is 48% (volume ratio), cultivated for 12 hours, and then separated and purified to produce 30 mg of nano-microbial cellulose.

Embodiment 3

[0023] Mix 5000 grams of apple juice, 300 grams of fructose, 4670 grams of tap water, 5 grams of potassium dihydrogen phosphate and 25 grams of ammonium sulfate to form a solution, adjust the pH value of the solution to 6, sterilize with microwave, cool to 34 ° C, add Acetobacter xylinum The C6MCC0603 bacterial strain is adjusted to a pH value of 6 every 2 hours in an incubator, and the gas-liquid ratio is 56% (volume ratio), cultivated for 24 hours, and then separated and purified to produce 8 mg of nano-microbial cellulose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com