Temperature measurement node point suspension thin film electric thermocouple

A technology of thermocouple and thin film, applied in thermoelectric devices, measuring heat, circuits, etc., can solve the problems of fluid motion interference, reduce the heat capacity of junctions, and reduce the response speed of thermocouples to temperature changes, etc., so as to improve the response rate and reduce the The effect of thermal inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

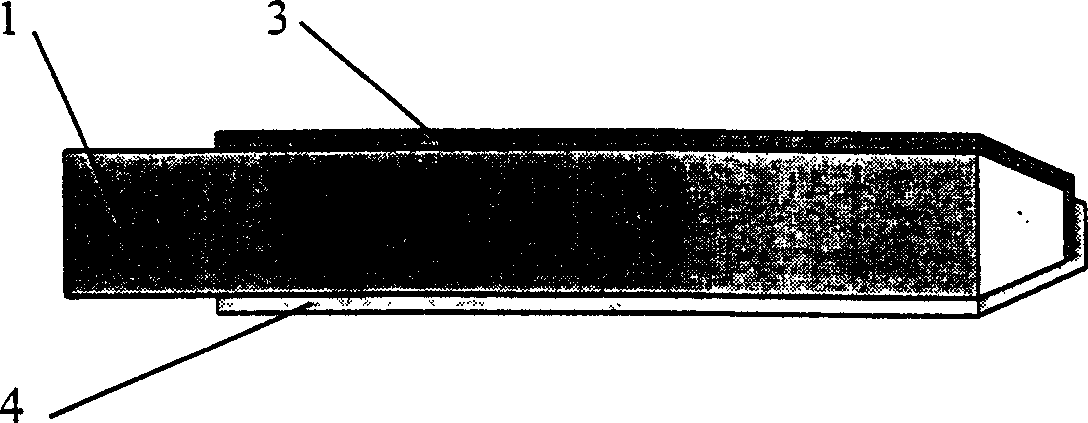

[0021] Example 1: Figure 3-1 To Fig. 3-5 is the schematic diagram of the manufacturing process of the present invention;

[0022] Such as Figure 3-1 As shown: the permanent substrate 1 is used as the structural basis of the thin-film thermocouple with the temperature-measuring node suspended in this embodiment, so that the thermocouple thin-film is attached to it, and lead contacts are provided;

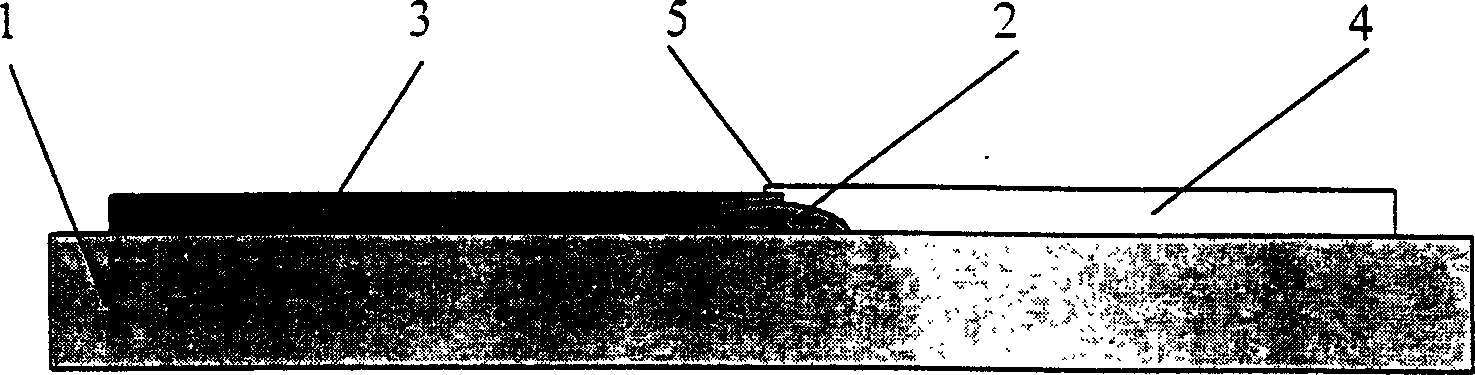

[0023] Figure 3-2 Shown: a non-permanent substrate 2 of smaller size is attached at the end or other specific location on the permanent substrate 1;

[0024] As shown in Figure 3-3: two kinds of thermocouple films 3 and 4 that constitute the film thermocouple suspended at the temperature measuring node are plated on the surface of the permanent substrate 1 respectively, and the intersection where the two thermocouple films overlap is is the temperature measuring junction 5 of the thermocouple;

[0025] Figure 3-43-3 is a view rotated 90° along its axis (i.e. the length direc...

Embodiment 2

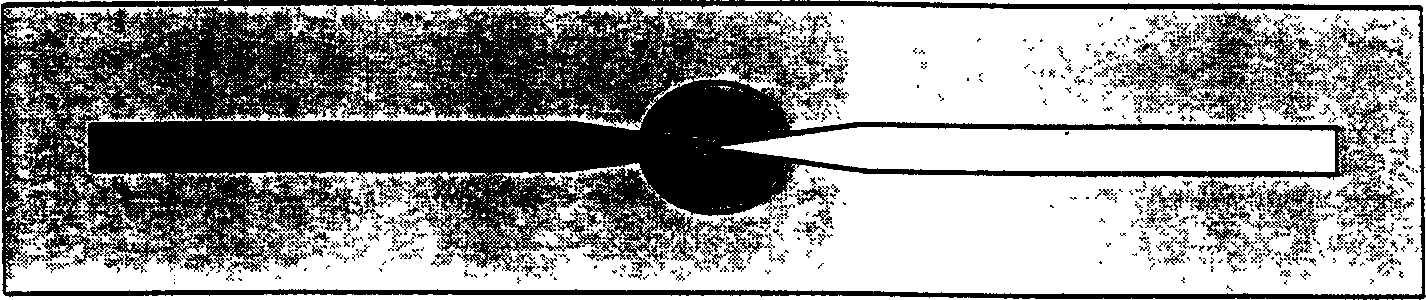

[0028] Thin film thermocouple provided by the present invention can have multiple forms, diagram 2-1 Another embodiment given is a suspended thin-film thermocouple whose base is a flat plate type, Figure 2-2 For the top view before removal of the non-permanent substrate 2, Figure 2-3 After removal of the non-permanent substrate 2, the node is in a suspended state.

[0029] Its production process is:

[0030] 1. A non-permanent base 2 with a small size is attached to the middle of the flat permanent base 1,

[0031] 2. On the flat-type permanent substrate 1, the non-permanent substrate 2 is used as the overlapping point to coat the thermocouple film 3 and the thermocouple film 4 on both ends respectively, and the thermocouple film 3 and the thermocouple film 4 are placed on the non-permanent overlap on base 2;

[0032] 3. The non-permanent substrate 2 is removed, that is, the fabrication of the thin-film thermocouple with the temperature measuring node 5 suspended in thi...

Embodiment 3

[0034] The production process of this embodiment is:

[0035] 1. Punch a hole in the middle of the permanent substrate 1 in the shape of a flat sheet, thin tube or thin rod, and attach a non-permanent substrate 2 in the hole;

[0036] 2. On the permanent substrate 1, use the non-permanent substrate 2 attached in the hole as the overlapping point to coat the thermocouple film 3 and the thermocouple film 4 on both ends respectively, and the thermocouple film 3 and the thermocouple film 4 are in the non-permanent overlay on base 2;

[0037] 3. Remove the non-permanent substrate 2 attached to the hole, that is, complete the fabrication of the thin-film thermocouple with the temperature measuring node suspended in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com