High temp. dry distillation treatment method for urban domestic refuse

A technology for municipal solid waste and high-temperature dry distillation, which is applied in the field of municipal solid waste treatment and can solve the problems of high energy consumption and cost, low utilization rate of waste resources, and difficulty in disposal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

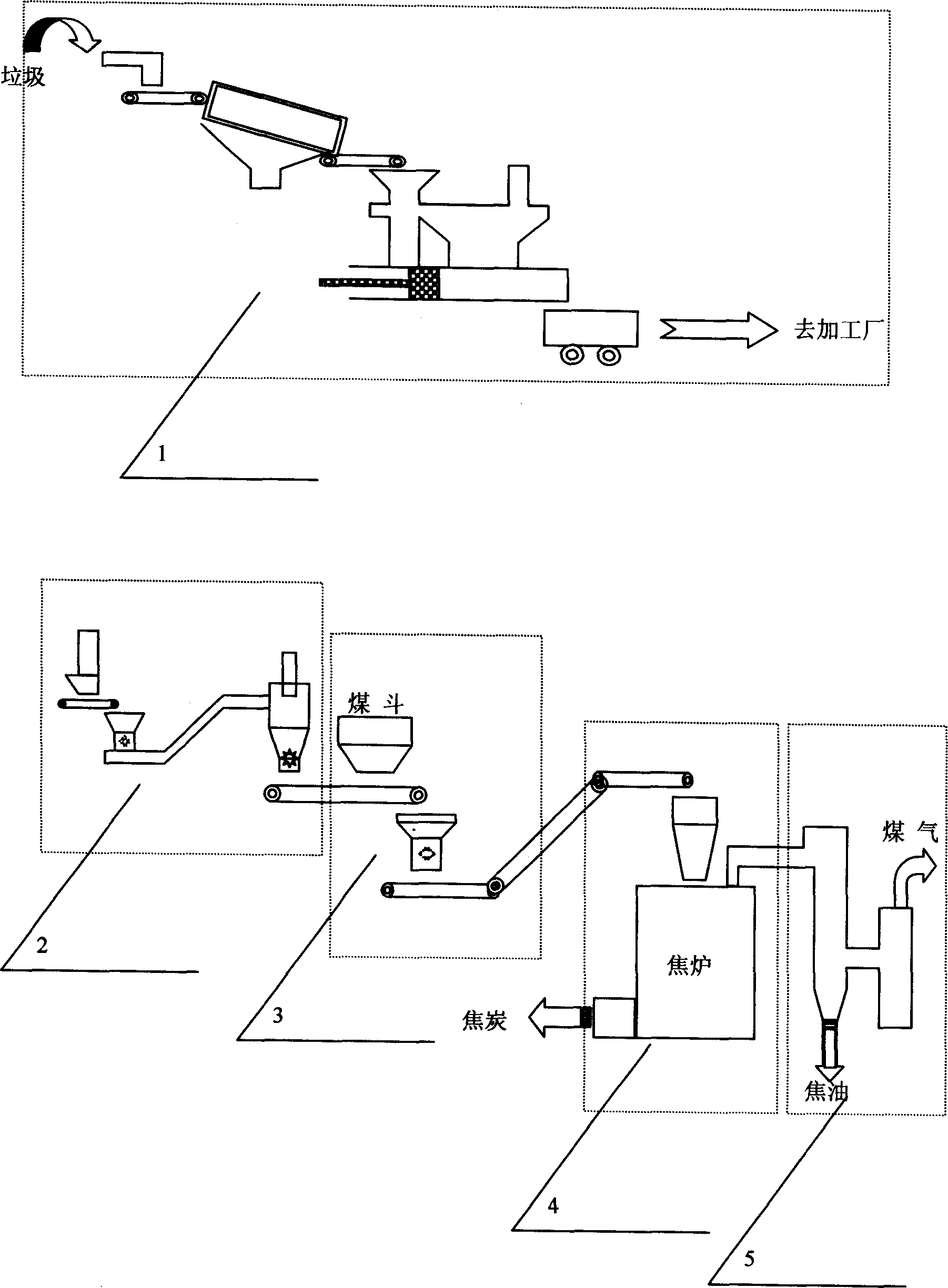

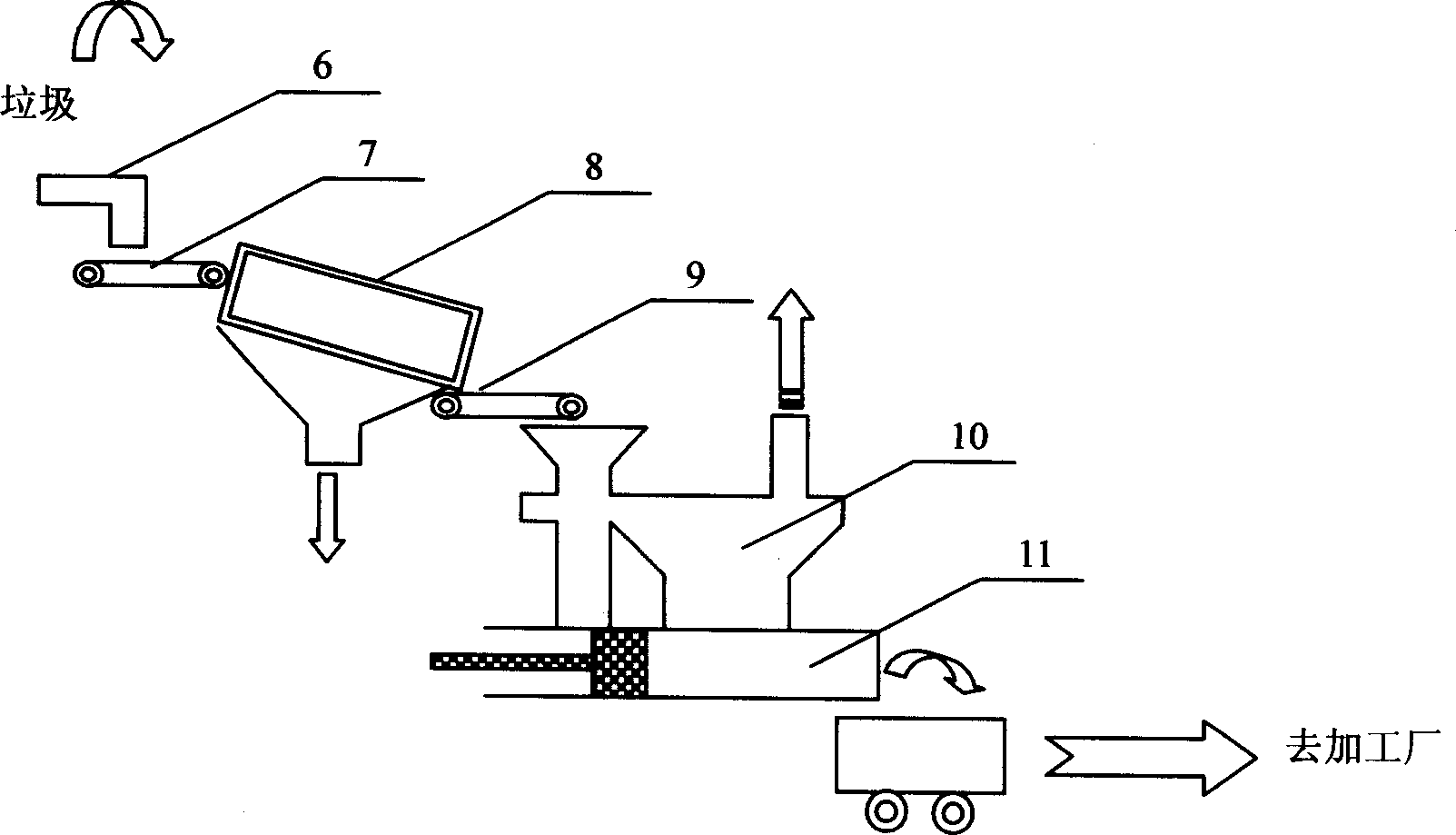

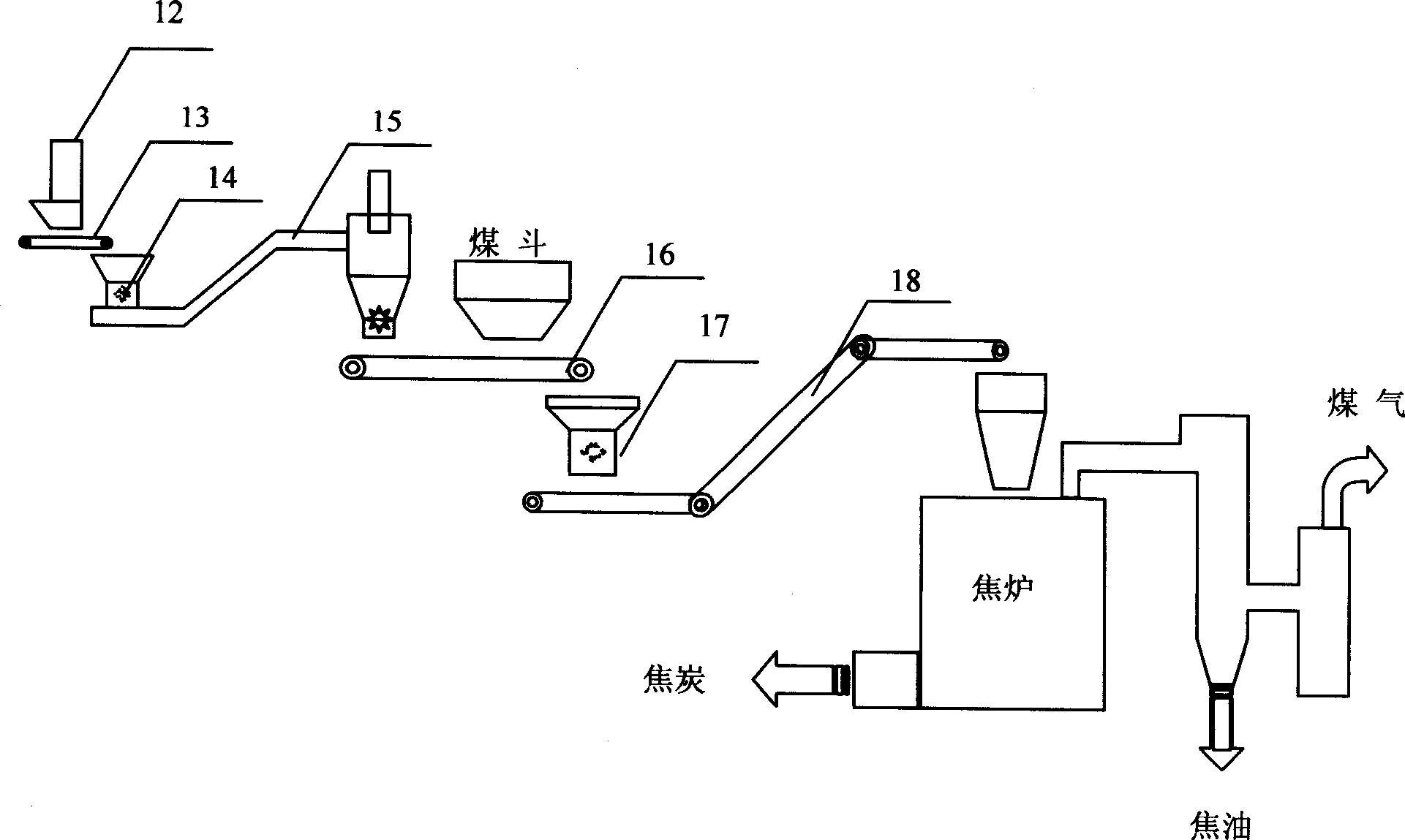

[0030]The implementation process of the above method is divided into three steps: the first step is to complete the supply of waste plastic raw materials through manual collection and mechanical sorting. The implementation process of the mechanical sorting method is as follows: (1) The original municipal solid waste is broken into bags and then enters the drum screening to remove small particles of waste materials (particle size less than 80mm); (3) The organic light components separated by winnowing are packed and processed as raw materials and transported to the processing plant to complete the raw material collection process. The second step is to break up the collected organic light waste raw materials, and then transport them to the crusher for processing through the belt. The feeder or screw feeder feeds the organic light waste in the silo into the coal conveying belt, and mixes with coal into the coal breaking system to complete the processing and transportation of orga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com