Improvements to methods for calefcation densification of a porous structure

A porous structure and densification technology, applied in applications, home appliances, ceramic products, etc., can solve problems such as poor energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

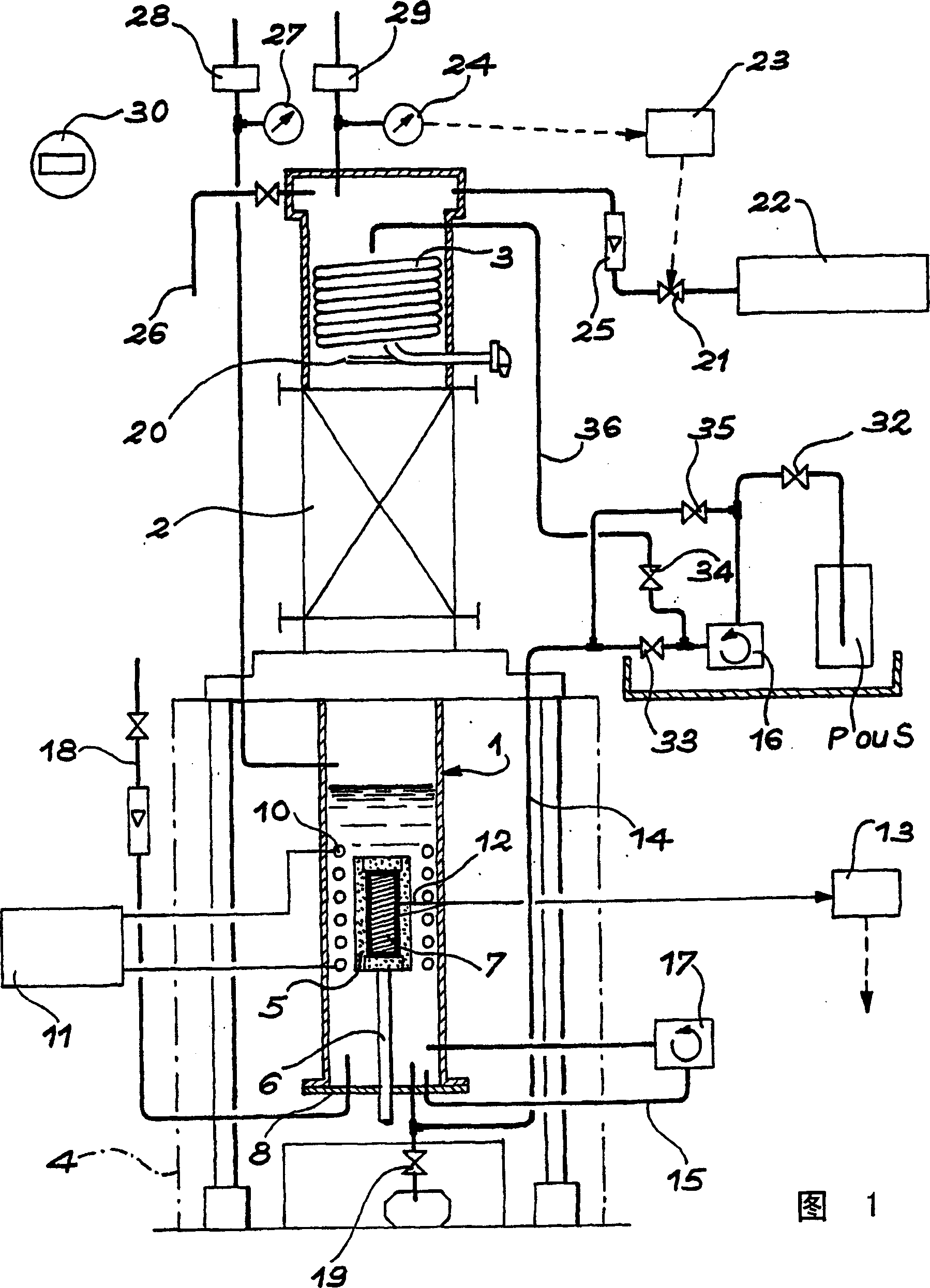

[0070] The reactor used had an internal diameter of 200 mm and a height of 300 mm. The inductor located in the reactor has a height of 150 mm and has 6 helical turns with internal and external diameters of 175 mm and 195 mm respectively.

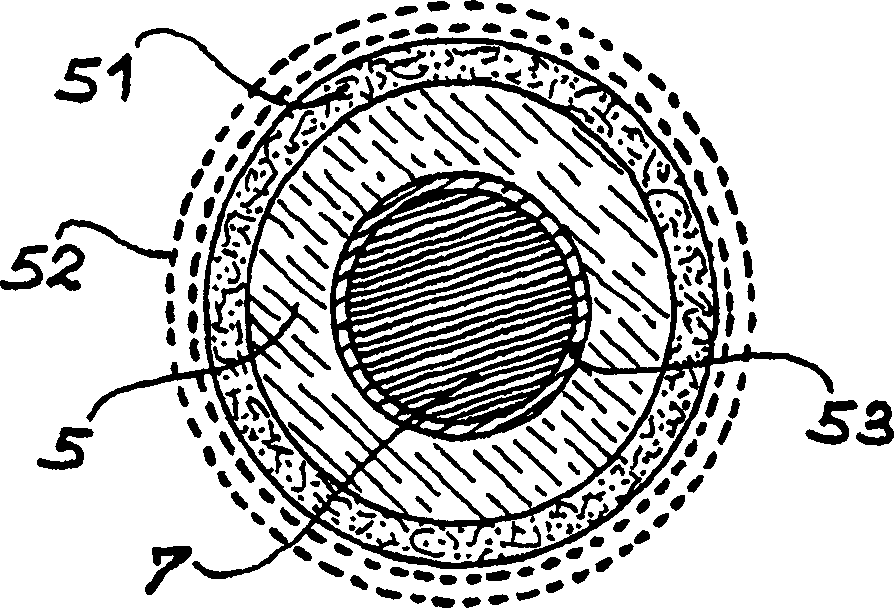

[0071] The susceptor used had a diameter of 80 mm and a height of 100 mm. The susceptor is completely covered by means of 3 carbon felt (density 0.40-0.45) parts to be densified:

[0072] - a hollow cylinder having internal and external diameters of 80 mm and 120 mm respectively covering its measured surface and a height of 100 mm;

[0073] - Two disks with a diameter of 120 mm and a thickness of 20 mm, covering the height and the bottom part of their two flat surfaces.

[0074] Fully covered with a felt made of two layers of Teflon GORE TBX It is composed of materials and has the following characteristics:

[0075] - thickness of one layer: 0.2 mm;

[0076] - Filtration: only particles with a diameter of less than 7.5 microns pass th...

Embodiment 2

[0090] This embodiment concerns the densification of small carbon parts. Heating is performed by electrical resistance.

[0091] The heating element is a graphite rod with a diameter of 3 mm. The heating element surrounds the sample to be densified, which is a felt tube of carbon (density 0.1 ) with a diameter of 2 cm and a height of 3 cm. Fully wrapped in a felt, as in Example 1, made of two layers of GORE-TEX Material composition.

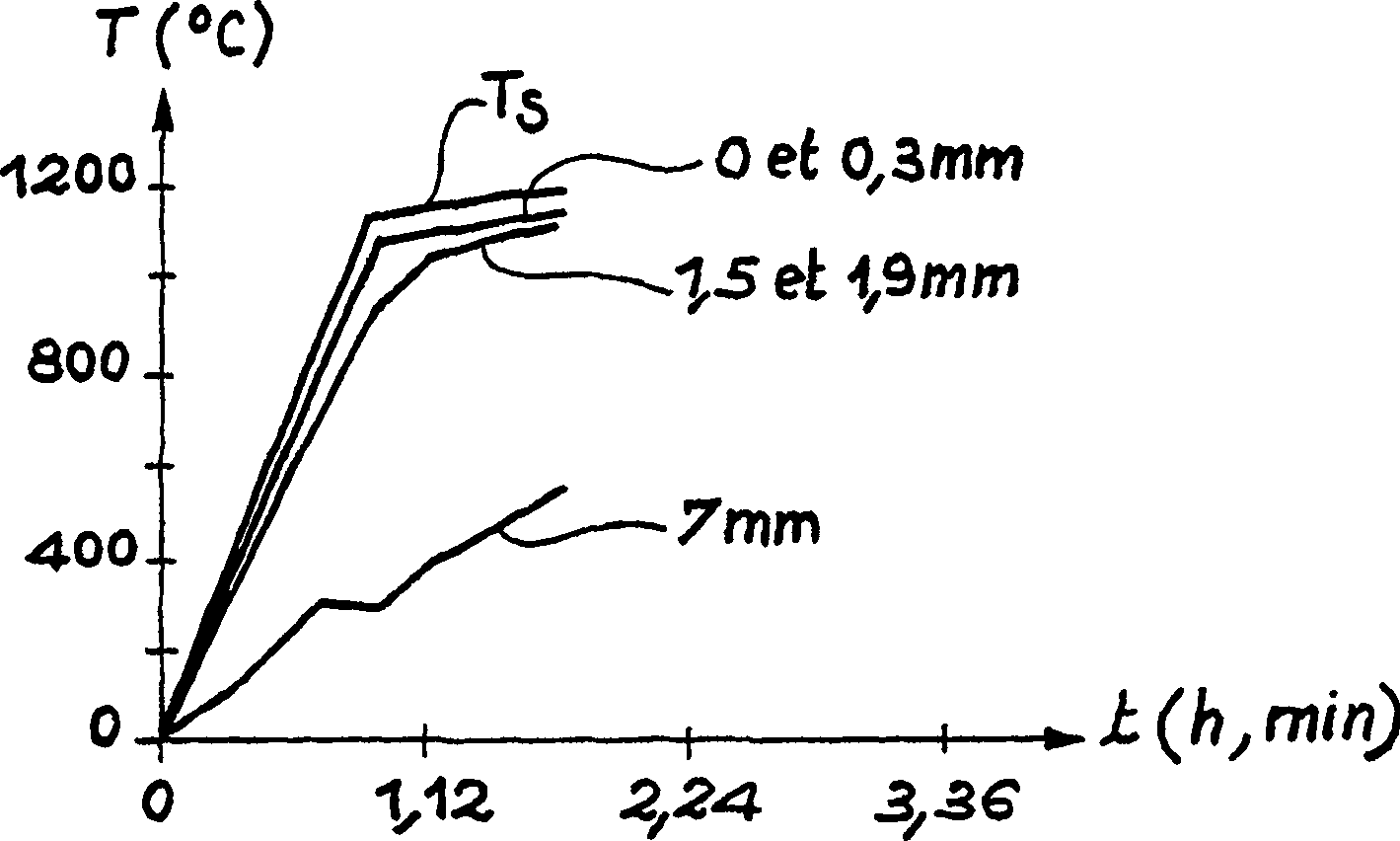

[0092] The pressure is fixed at 0.1Mpa. The temperature was raised at a rate of 1000°C / h until reaching 100°C. The temperature was maintained at 1100° C. during 30 minutes, and then the temperature was lowered at a rate of 1000° C. / h.

[0093] The result is as follows:

[0094] - densification speed of 4 mm / h;

[0095] - Energy consumption of 110kWh / kg deposited carbon;

[0096] - Density is 1.8.

[0097] For comparison, under the same conditions without GORE-TEX felt,

[0098] - The speed is 0.6mm / h;

[0099] - energy consumption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com