Nano sized intellectual driving unit with large feeding force for super precisively machining

A technology for ultra-precision machining and driving components, which is applied in metal processing mechanical parts, manufacturing tools, metal processing and other directions, can solve the problem of small driving force, and achieve the effect of preventing stress concentration, increasing the feed range and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

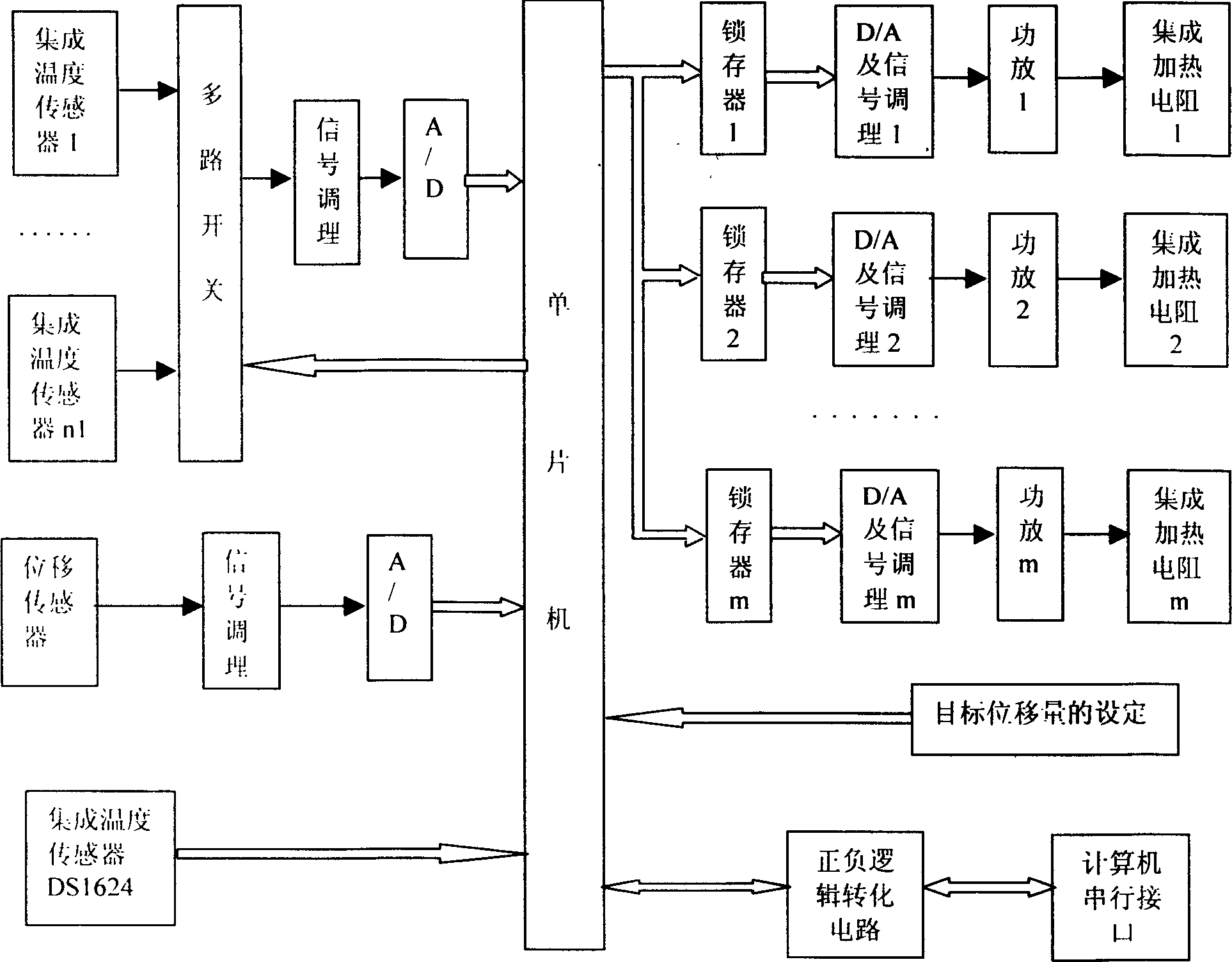

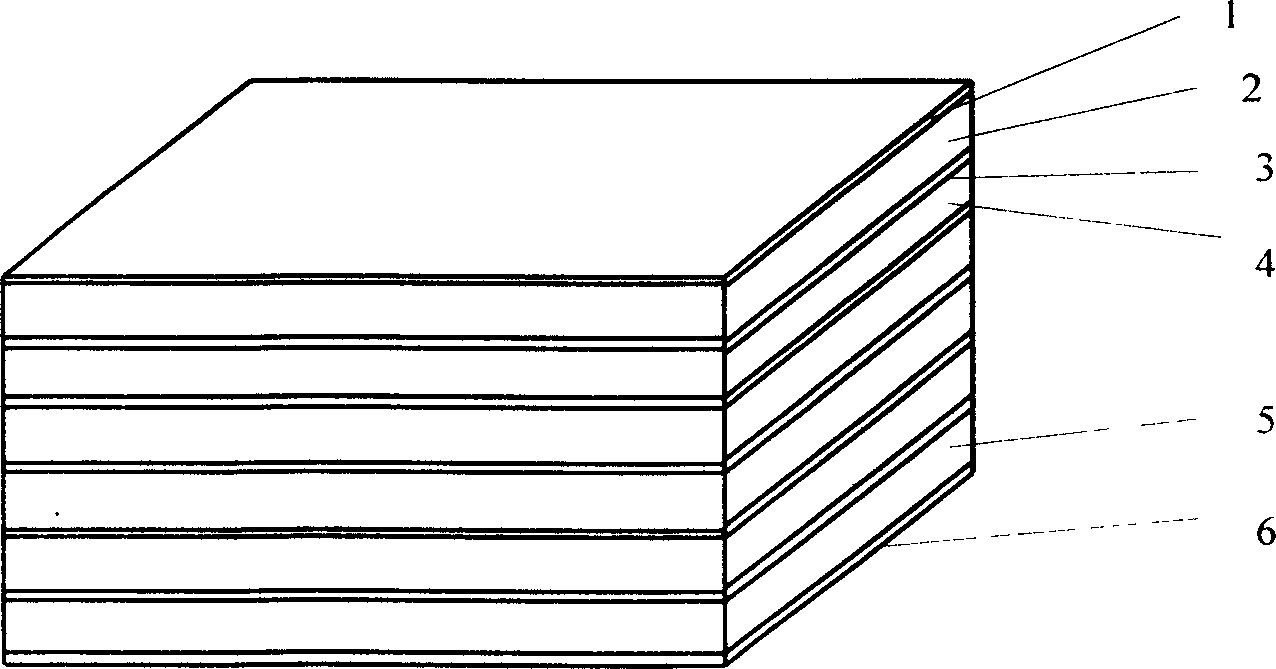

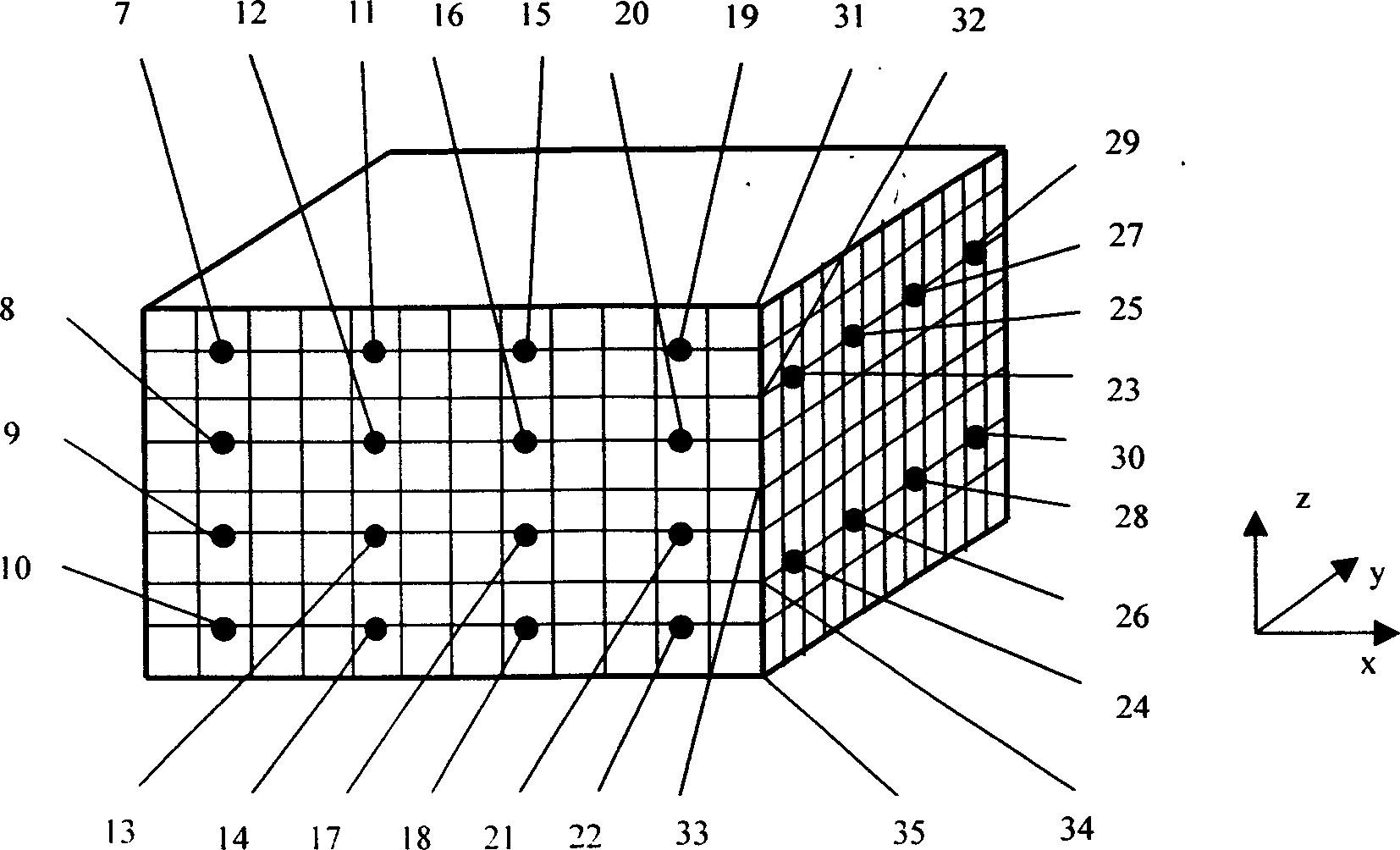

[0015] The key point of the present invention is to use each piece of deformation body with intelligent structure as the actuator, and according to the principle of thermal expansion and cold contraction, by controlling the internal heat source with mesh structure in each piece of deformation body, the temperature field is changed, and then the displacement is controlled. purpose of the field. Since the thermal displacement of the feeding surface of the nanoscale driving component is directly used as active feeding, the research on thermal deformation has shifted from passive compensation to active application. figure 2 Among them, the nano-scale intelligent drive components with large feed force are structurally composed of various deformation bodies in series, the purpose is to expand the feed range as much as possible without changing the feed resolution. In order to facilitate the control and prevent mutual heat conduction between the deformed bodies and between the defor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com